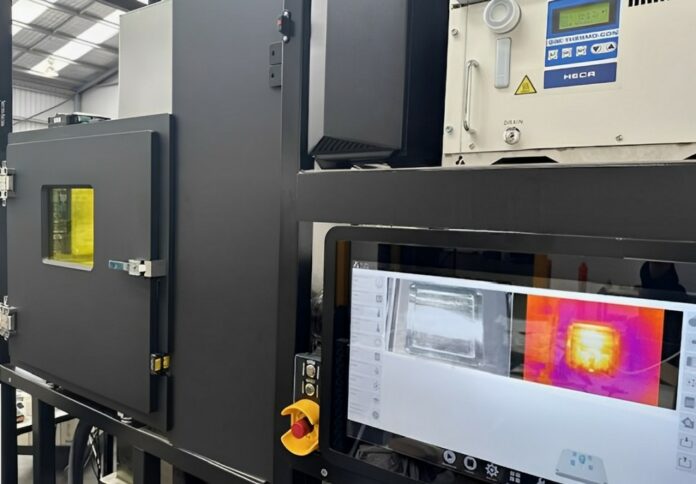

Aurora Labs Limited (A3D) announced it provides the latest industrial printing metal printer AL250 3D. Designed, engineered, and made by the company in its Australia-based facility, the AL250 3D metal printer can be mainly deployed for oil & gas, defense, and aerospace applications.

The Aurora Labs AL250 is equipped to print mid-sized intricate geometries. The company can dedicate specific powders to specific printers by obviating the need for powder changing between jobs. This reduces the risk of powder contamination and cuts downtime.

Rebekah Letheby, CEO of Aurora reveals, “The AL250 3D printer is improving our industrial printing service and machine building abilities. It will meet the increasing demand for specialized materials as we expand our capabilities and scale up production for the defense industry, reinforcing our commitment to developing machines tailored for practical industrial printing applications. The AL250 equips multiple commercial features, ensuring a user-friendly and seamless experience. Its compact, easy-to-clean build chamber supports a generous 250x250x300mm 3D print area. This machine excels at printing intricate, mid-sized geometries, making it a valuable addition to our expanding print service.”

Key focus on Inconel 625

One of the first materials that can already be processed by the AL250 system is Inconel 625. According to the company, this nickel-based super alloy can deliver hardness as built 315 HV10 and part density at 8.4g/cm3. As a reminder, the material is acknowledged for delivering strength & its ability to withstand temperature and corrosion.

At first, one may expect full-scale micro gas turbines as the first applications achieved in this alloy. Other applications will follow in the area of microgas turbines and related parts. Using the AL250 can facilitate streamlined operations since specific powders can be used on specific printers without requiring change materials between print jobs, reducing this way downtime and the risk of powder contamination.

Lastly, providing AM services with this new 3D printer will help customers see its potential, and downstream customer support and better assess its viability for their production needs.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.