This week at RAPID+TCT 2024, Material producers Alloyed and Aubert & Duval have announced the release of a new nickel superalloy. Named ABD®-1000AM, the material has been developed specifically for AM. This launch marks the expansion of an agreement both companies previously signed. Under the terms of that agreement, Aubert & Duval has been named Alloyed’s production partner for ABD®-1000AM – an, supplying Alloyed with the powder feedstock that it is using to manufacture components.

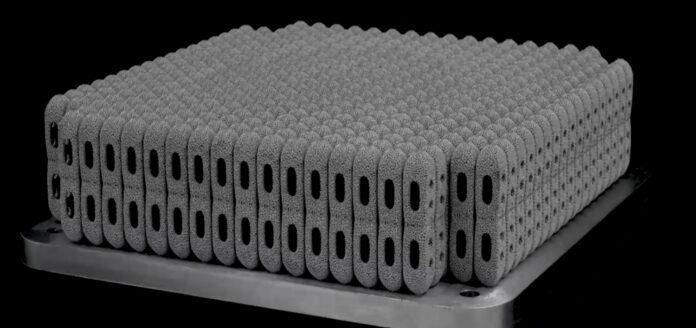

Designed using Alloyed’s computational Alloys-by-Design® platform, the new ultra-high-temperature nickel alloy (ABD®-1000AM) provides excellent environmental resistance and high-temperature strength, with a working temperature range beyond 1000°C (1832°F) in its age-hardened state. Compared to cast alloy Ni247LC, the alloy offers near-equivalent stress rupture life while allowing crack-free additive manufacture and heat treatment, enabling complex part design for components within the aerospace, power, automotive, defence and space industries.

Jean-François Juéry, EVP Business development & Strategy of Aubert & Duval, said: “[…] We are convinced that Additive Manufacturing technology combined with high-temperature powder Alloys is a promising solution in particular to achieve carbon footprint reduction in various industries: over the last five years, we have indeed seen huge growth in interest and orders for these innovative alloys across all industrial sectors, so we are excited to see what new products and performance gains will be enabled by the commercial availability of ABD®-1000AM.”

The AM industry has long sought to be able to manufacture parts in alumina-forming alloys such as Ni247LC and Ni713, though the susceptibility of these alloys to cracking has significantly limited the maturity that’s been reached, resulting in very few applications that can make use of them. Designed to be free of solidification, liquidation, and strain-age cracks, ABD®-1000AM would showcase good processability. The typical microstructure is characterized by a relative density above 99.9% and low defect levels, consisting of 55% gamma prime phase fraction in the age-hardenable state, a characteristic that was only made possible through the use of Alloyed’s ABD® platform to design the alloy specifically for the characteristics of the AM process.

Michael Holmes, CEO of Alloyed, commented: “Extending our portfolio of alloys through the introduction of ABD®-1000AM is a really exciting next step for Alloyed, greatly expanding our capability to deliver AM parts that can operate in some of the most extreme environments, and we’re thrilled to be doing it with Aubert & Duval as our trusted partner […].”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com