During its debut at Formnext 2025, ATLIX introduced not only a new brand but also a renewed vision for industrial additive manufacturing. Matthias Himmelsbach, CEO of ATLIX, walked us through this transformation.

Previously Head of Additive Manufacturing at TRUMPF Additive Manufacturing, he brings both continuity and credibility: a familiar face with a mindset customers already trust.

Going back to Italian roots

Although TRUMPF was headquartered in Germany, ATLIX will now establish its headquarters in Italy, where the journey originally began through the joint venture TRUMPF signed with laser specialist Sisma in 2014. Despite the significant rebranding, one element remains unchanged: the machines are, and have always been, manufactured in Italy.

On the booth, it was clear that ATLIX does not intend to erase TRUMPF’s legacy. The company has kept the iconic TRUMPF blue to honor its past. While a new product naming is expected in the coming months, Himmelsbach notes that ATLIX’s brand identity will continue to evolve to reflect reliability, scalability, and industrial-ready manufacturing.

“We have maintained the blue from TRUMPF, which is our heritage and we’re very proud of our heritage… and we want our customers to recognize our legacy. We want to deliver very reliable, robust and scalable products and services. This is the core element of our brand,” he says.

To reflect these robust services, the CEO emphasized the capabilities of the TruPrint 5000, one of the 3D printers that marks their presence at Formnext.

The newest generation of the TruPrint series

The newest generation of the TruPrint series

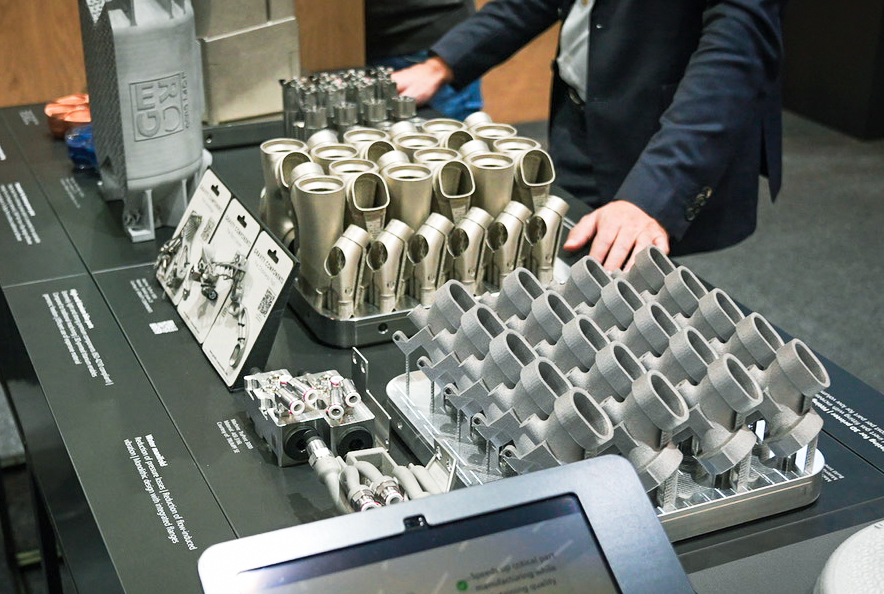

The TruPrint platform is a fully automated, highly productive metal additive manufacturing system designed for series production. Those who knew TRUMPF’s portfolio may already be familiar with the 5000 industrial 3D printer.

What changed is that the new generation is significantly redesigned, scaling from a 300 mm round build cylinder to a 500 × 500 mm square platform.

“This industrial 3D printer has been designed to bring down the cost per part to the lowest level possible,” Himmelsbach states. Depending on the application, the cost improvements can be dramatic. For example, suppressor production can be cut by more than half compared to the previous platform.

Additionally, for years, TRUMPF relied on round cylinders. ATLIX has broken from that tradition.

This shift is driven by application needs, as the geometry must always serve the part. According to Himmelsbach, square cylinders provide up to 30–50% more usable space depending on part geometry, enabling higher productivity and better platform utilization.

This design evolution is not only reflected in the new TruPrint 5000 generation but also, in the newly launched TruPrint 3000. Only the TruPrint 1000 retains its round platform, as it remains the most suitable shape for its typical applications, such as crowns, bridges, and other small dental parts.

Other key specifications include:

The 3D printer integrates a standard build height (400 mm), with future expandability for taller parts and an automatic multi-laser alignment system. It can process multiple alloys. Interestingly, the material changeover can be done in just three days.

Equipped with four 1kW lasers, ATLIX deliberately avoids installing six or eight lasers as often seen in most 3D printers of the same range. According to the CEO, additional beams raise system cost without necessarily providing meaningful productivity gains for this platform size.

The new TruPrint 5000 enables fully automated, continuous production through a seamless linear workflow in which empty build cylinders are loaded on one side of the machine, automatically leveled, sealed air-tight, and started without operator intervention.

Once a build job is complete, the machine automatically unloads the finished cylinder on the opposite side, where it can cool independently, and immediately loads the next one, restarting the process within just 15 minutes. This closed-loop automation eliminates downtime and prevents jobs from ending unattended during off-hours.

This update reflects ATLIX’s strategy: develop machine architectures tailored to specific industry needs; in this case, aerospace, defense, and semiconductors.

And now…?

And now…?

With the launch of the new TruPrint 5000 and the introduction of the ATLIX brand, the company signals both continuity and transformation, honoring its legacy while confidently stepping into a new industrial era. The blend of Italian roots, German engineering heritage, and a renewed strategic vision sets the stage for a compelling future. I can’t wait to see how this next era will be shaped.