Plastometrex continues to position its mechanical testing solution as a viable solution for additive manufacturing (AM) applications in the defense industry. On the heels of its collaboration with Fieldmade, the company joined forces with ASTRO America (ASTRO), a non-profit research institute advancing manufacturing technology and policy in aerospace and defense.

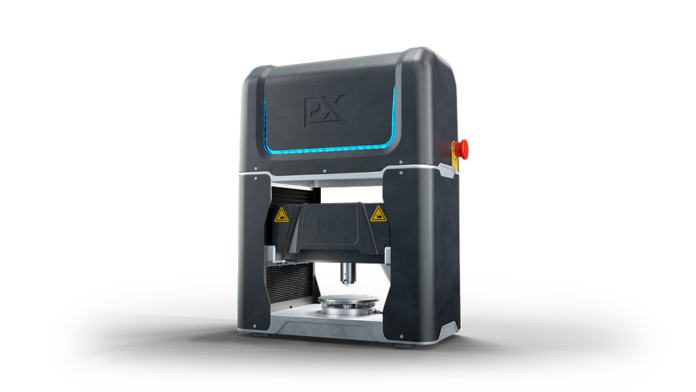

They integrate Plastometrex’s PLX-Benchtop into ASTRO’s additive friction stir deposition (AFSD) testing processes to improve ASTRO’s parameter development workflows.

After several tests using the system, ASTRO could refine its additive manufacturing parameters in aluminum alloys produced with a MELD print head.

“The ability to conduct fast, non-destructive mechanical testing with PIP has significantly improved our approach to material optimization,” said Noah Barnhill, Vice President, Army Operations at ASTRO America. “We can now evaluate mechanical properties in real time, making data-driven decisions about process parameters without the delays and material constraints of conventional testing methods.”

The Profilometry-based Indentation Plastometry (PIP) technology enables ASTRO to obtain accurate stress-strain curves in minutes and at a fraction of the cost of tensile testing, bringing mechanical testing into the development cycle earlier. This has allowed ASTRO’s team to identify parameter influences that would have been cost-prohibitive to assess with traditional tensile testing methods.

Beyond parameter development, the PLX-Benchtop enables ASTRO to assess part homogeneity, an insight that was previously impractical using tensile testing due to the challenges of extracting specimens from real components. With the flexibility to test directly on printed parts, ASTRO can now evaluate localized variations in mechanical properties, improving quality assurance for AFSD-processed materials.

“Traditional mechanical testing methods often limit the scope of what’s feasible in additive manufacturing R&D,” said Dr. Mike Coto, CCO at Plastometrex. “ASTRO’s use of the PLX-Benchtop demonstrates how rapid, cost-effective mechanical testing can unlock deeper insights into process optimization, material performance, and component reliability – without the cost and time barriers of traditional tensile testing.”

As ASTRO expands its testing across different materials and process parameters, Plastometrex and ASTRO will continue to explore new ways of integrating PIP-based testing into industrial AM workflows, a press release states.

Looking for a job in the AM industry or hiring new talent? You can post job opportunities on 3D ADEPT Media for free or explore openings via our job board. Stay connected by following us on Facebook, Twitter, LinkedIn & Instagram, and subscribe to our weekly newsletter for the latest updates. Have a story to share or want to be featured in our next digital magazine issue? Send it to editor@3dadept.com !