A new partnership agreement will see the use of Titomic Kinetic Fusion metal additive manufacturing at Ascent Aerospace, a US-based company that delivers a variety of products & solutions to the aerospace, defense & space industries. The announcement follows the sales contract the Australian manufacturer has signed with another Defense supplier.

As far as this agreement is concerned, Titomic KF will play a key role in the global tooling market, a field that is expected to grow at CAGR 8% to $368.5 billion by 2026.

From wing components and fuselage structures to final assembly lines, aerostructure assembly requirements are often challenging and might be facilitated depending on the leveraged process. Over time, Ascent has been able to develop strategic alliances with manufacturers in the aforementioned industries. The company works with airframers to develop their project and see it through from process design and engineering to build and installation.

Mr. Michael Mahfet, CEO of Ascent Aerospace, stated: “Our focused research & development activities in additive manufacturing technologies aligns with Ascent’s multi-year technology roadmap and realization of expansive efforts studying the benefits of these technologies within the aerospace tooling market. Staying at the forefront of additive manufacturing positions us to remain the leader in new and innovative tooling solutions, supporting strong collaboration with our customers and supplementing our in-house, vertically integrated design and fabrication capabilities. We look forward to working with Titomic in the advancement of metallic 3D printing for the aerospace tooling industry.”

As part of this partnership, the focus will be made on a Validation Phase and an Adoption Phase.

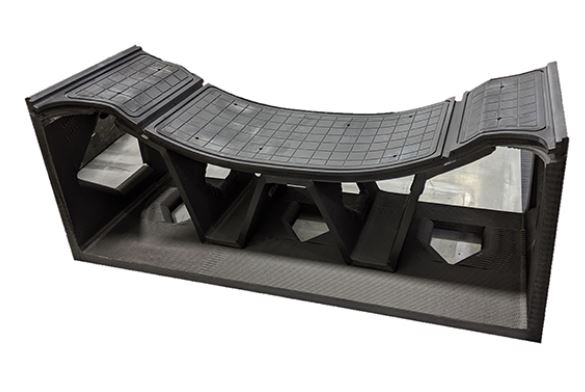

Titomic will deliver an Ascent customer approved Invar36 tool manufactured using the TKF9000 metal additive manufacturing system. The tool will be used to perform a test and production feasibility trial.

The second phase will consist in implementing joint-sales strategy to provide aerospace tooling using TKF’s metal AM process. The overall goal is to reduce the long lead-times to meet the growing global demand.

Based on its research and development of metal tooling for the aerospace and defence industries, the metal AM specialist will be able to offer aerospace specialist a new tooling manufacturing option that will have a key impact on performance, part production and reduced lead times.

Mr. Jeff Lang, Titomic Managing Director, comments on this partnership: “The significant increase in the global tooling market is being driven by the aerospace and defence industries’ compounding need for higher production rates of carbon fiber parts. The increased use of carbon fiber parts in commercial aircraft has created a backlog in the supply of tooling that is not being resolved. Titomic’s partnership with Ascent Aerospace makes strategic sense to further validate the commercial opportunities for industrial scale metal additive manufacturing using Titomic’s TKF systems to resolve this current, and ongoing, backlog for tooling. Ascent Aerospace’s notable achievements in producing the largest Invar molds ever made, and as one of the largest composite tooling manufacturers in the world, provides both companies with an inflection point to disrupt the traditional tooling industry by providing a more efficient manufacturing using Titomic’s TKF systems to deliver more sustainable tooling supply to meet increasing global demand.”

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com