Specialty chemicals company Asahi Kasei Plastics North America (APNA) has launched a portfolio of filaments for the 3D printing industry. The launch marks the official launch of the company’s activities in the AM industry. Until now, it had been a silent player through its investment in CASTOR.

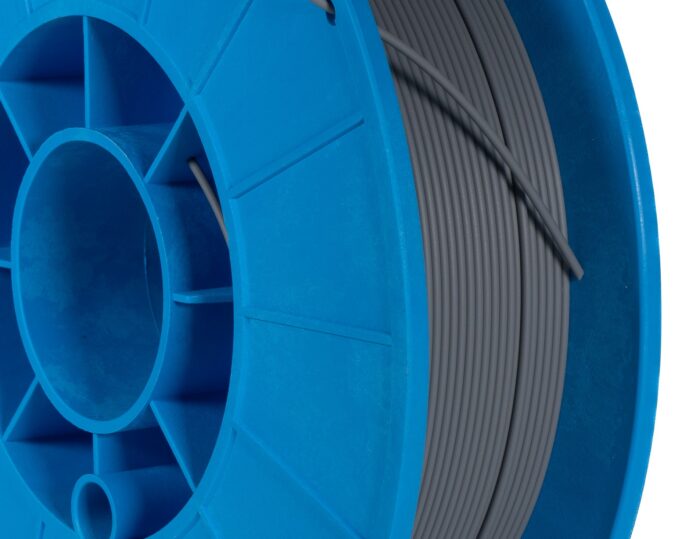

Designed to meet manufacturing needs across industrial, aerospace, and automotive sectors, the first line of the new filaments is made from XYRON™, APNA’s modified polyphenylene ether resin (m-PPE), known for its excellent balance of heat resistance and impact strength. This material replaces polycarbonate–acrylonitrile butadiene styrene (PC-ABS), and polyetherimide (PEI) alternatives in various applications. The second line is made from Thermylene® polypropylene (PP) resin and offers high strength and stiffness, does not require drying, and has lower warpage compared to traditional unfilled polypropylene alternatives.

“Everyone comes to NPE to see the latest innovations, and we are excited to show our strength as a leader in the industry with resin technology, 3D printing filaments, and purging compounds under one structure,” said Phani Nagaraj, President at APNA

Asahi Kasei’s line-up includes PPE/PS, PA/PPE, PP/PPE, and PPS/PPE.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.