In the May/June Issue of 3D ADEPT Mag, we shared some insights into ULT AG’s activities, a global company that aims at removing hazardous particles in various manufacturing processes. The company provides the AM industry with advice and product assessment on everything related to air pollution control, occupational safety as well as air drying in plastic and metal AM processes. The first step towards appropriate use of air technologies solutions consists in understanding their specifications and how each of these technologies should be leveraged.

In this feature, Alexander Jakschik, Managing Director/CTO at ULT AG helps industrials to understand when they should rely on air technologies solutions. He also reveals key tips to know which air technology solution fits best a company’s needs.

Why do I need an air technology solution?

First of all, let’s keep in mind that this article will focus on three main solutions provided by ULT AG to the AM industry: extraction, filtration, and air-drying technology. These technologies can be utilized either in the workplace or more specifically alongside the 3D Printer.

Air’s ability to contain and to convey liquids, solids and living particles is quite overlooked. The reason sometimes is simple: as we do not see these particles, we can’t properly assess their impact on the end part or the operator health.

Yet, research demonstrates that 3D Printed parts often suffer from the impact of impurities in the construction chamber. Even once purged, those impurities can have a damaging impact on the 3D Printed part or alter the desired mechanical properties of the part, especially when sensitive materials are utilized during the production.

Seven forms of impurities can influence the AM process, machines and products. They can also cause significant health risks for operators: macro dust, nano dust, solvent vapors, noxious gases, foreign particles, oxygen in inert gases and air humidity.

“The extraction and filtration process starts with pollutant or air capturing, as you can only filter what has been captured before. Contaminants or air streams are captured using specially designed capturing elements. This highly important step requires strong expertise. Particularly contaminants in AM are nanoscale and almost do not sink to the bottom. Plenty of know-how is required to capture these airborne pollutants”, Alexander Jakschik points out.

Indeed, these pollutants occur at different stages of the production process, therefore, have a different impact on operators, the manufactured product or even the 3D Printer’s functioning.

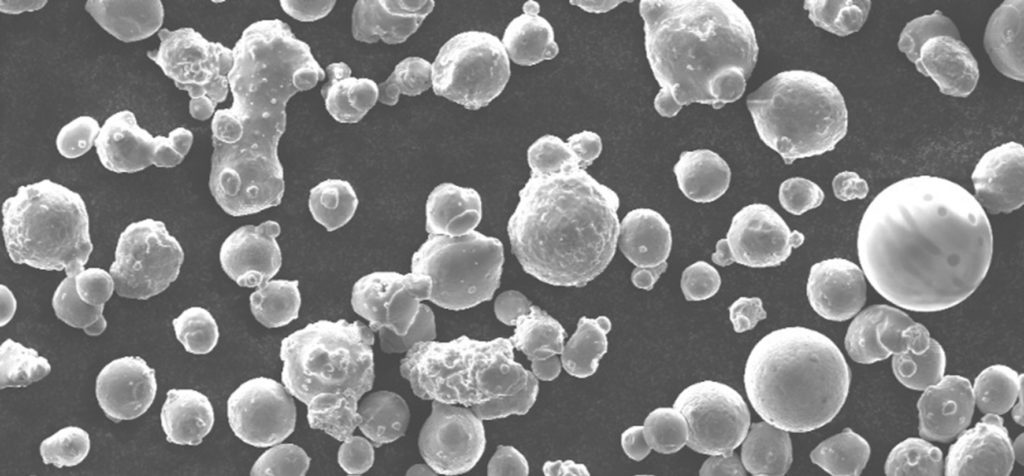

Nano dust for instance, is usually seen in melting processes, during a production that requires the use of powder materials.

Solvent vapors can be released during outgassing of liquid synthetic resin and cleaning of products. These solvent vapors can be a nerve poison, can cause eye damage or can even be a risk for the operator’s breathing.

Noxious gases pollutants can be released when melting powder materials during production processes. Due to contamination of powder materials and liquid synthetic resins, these pollutants can have a detrimental effect on the manufactured part. Furthermore, in the workplace, dust particles that remain in the air can contaminate the materials and have a similar impact on the manufactured part.

These examples show that air pollutants can have an impact at different stages of the AM process. That’s why, to tackle them, they require different types of air technologies solutions.

In this vein, Alexander underlines the different stages of the AM process that require dedicated solutions:

“[There are] solutions for AM process preparation. Drying technology is utilized during the handling of powder under defined dry conditions for better material and process quality. Air cleaning technology comes into play when operating with powders under safe and health conditions.

[Next in the line are] solutions for the AM process. Inert gas cleaning technologies (e.g. Argon, Nitrogen) are required for safe and stable processes. ULT offers solutions for powder bed fusion, material extrusion, and more. They are implemented either as an integrated solution or as retro-fit.

[And] solutions for post-processing which include vacuum cleaners such as process chamber cleaning, as well as air cleaning at manual workplaces (required when removing printing support material or smoothing phases). Not to mention that air cleaning is also used at unpacking stations or depowdering stations.”

Very often, additive manufacturing outlines are only assessed from the prism of the printing process. By highlighting these different stages, ULT AG’s Managing Director also highlights the need to address the issue at both the pre- and post-processing stages of the manufacturing.

Interestingly, the use of each air technology solution also depends on the AM technologies leveraged, hence the need to know which solution fits best each manufacturer.

Which solution fits your organization?

Air handling jobs can be performed both on the processing of metal, plastic, and ceramics powders as well as on the processing of plastic fibers and liquid synthetic resins.

Based on the aforementioned description of air pollutants impact, one notes that air technologies solutions mostly fit with selective laser melting and stereolithography technologies. However, further applications of these technologies can be explored for FDM processes and other forms of metal AM technologies including electron beam melting and laser deposition welding.

Air drying technologies, as well as extraction and filtration technologies, can be used for each of these AM technologies.

Air drying technologies come into play when the operator must process powders while meeting safety and quality requirements. In this regard, „it is important to ensure constant air humidity in the powder storage or production rooms. It helps prevent water from attaching to the powder and negatively influencing the process quality of the selective laser melting process or leading to corrosion”, Alexander states.

As for extraction technologies, they require the use of unpacking stations as well as post-processing systems for metal 3D Printing processes. As their name implies, they help remove powders that are downstream from the AM process into an optimized system.

“The powder itself is in the micrometer range. The particles that are created during processing are nanoscale. This particle size hardly sinks to the bottom and remains in the air. It can, therefore, be distributed anywhere in the room or dragged into the home. Such particles overcome the lung-blood barrier and are distributed throughout the body and the brain, where they may cause irreversible damage.

Also, it is advisable to subject the entire production area to air purification in order to ensure cleanliness in the production process and to prevent the particles from being carried over into the home.

Furthermore, ULT AG also provides industrial vacuum cleaners. Thus, the excess powder can be safely removed from the machines and in the production environment”, Alexander Jakschik explains.

Unpacking stations are a further step towards the flexible use and industrialization of AM. They are integrated into the AM material management system and help to establish a seamless powder processing chain. The good news is, they can be used no matter what the number of production machines is.

Application of air-drying technologies with Selective Laser Melting

SLM-based technologies always require the use of extraction technologies. Used in the form of gas cleaning, these technologies enable operators to maintain a stable and safe process.

ULT has built up extensive experience in applications with this AM process and has conducted further research in the field to explore new possibilities to improve the production environment.

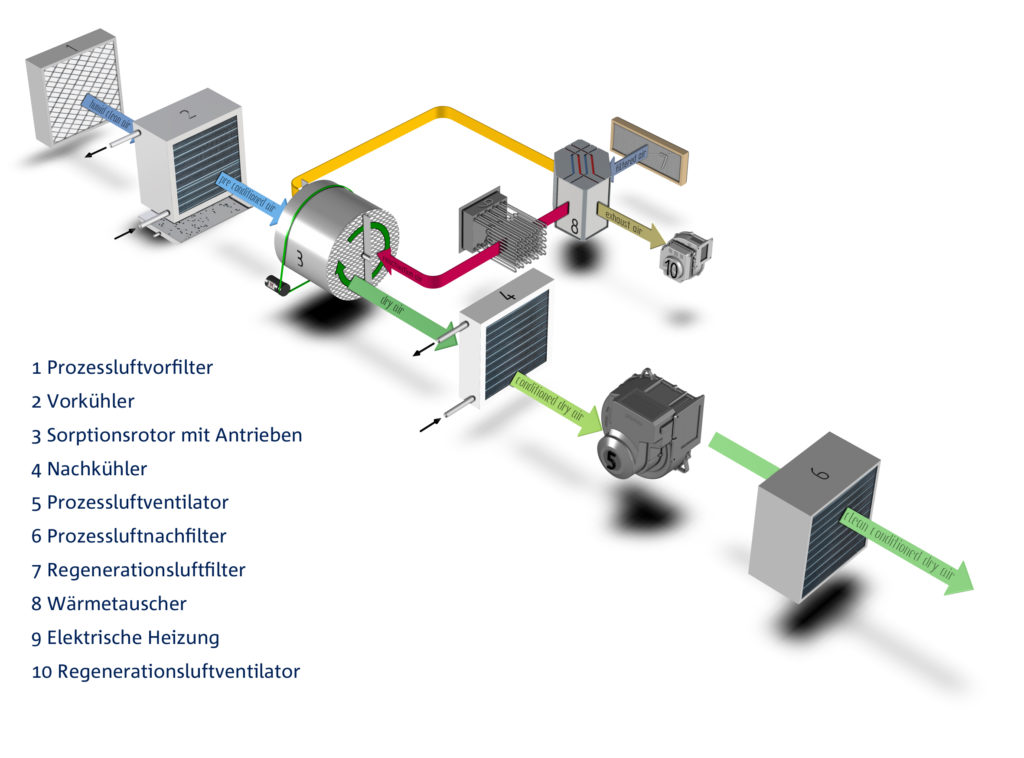

“Based on experience and intensive research, they have defined a multi-level filter concept, for [ different processes including] selective laser melting processes. Coarse and fine particles are filtered through several stages. The filters must be designed in the way they can handle flammable or explosive substances safely. In terms of air-drying systems, we have decided for sorption technology to achieve extremely low dew point temperatures. The most important component of such a system is the specially coated sorption wheel/rotor. It rotates at a speed adapted to the process and absorbs the moisture from the process airflow. In countercurrent, warm air is led through the sorption rotor, which removes the moisture from it. The water-laden exhaust air is then released into the environment outside the process area”, the MD states.

Concluding thoughts

The integration of air-drying technologies requires to pay attention to several parameters, from AM systems specifications to the use of materials leveraged and the workplace. In this case, personalized advice is often best as it can determine how efficient a company’s air treatment solution can be.

Several issues regarding this topic still need to be addressed, in light of the current development of automated AM solutions. However, the biggest issue today, is to raise awareness on the impact of harmful substances in 3D printing. As they are an invisible danger, their effects are only likely to be seen in a few years.

“The particles and gaseous substances are not visible (because they are nanoscale) and often cannot be smelled. Therefore, there is hardly any problem awareness. The effects are often visible years after application [and at that moment], they are no longer reversible. Particles cross the lung-blood barrier and are distributed in the body and brain.

I wish for the future that the understanding for it grows more and more and that we can all guarantee safe and clean production processes in the future”, Alexander Jakschik concludes.

This content has been written in collaboration with ULT AG.

Remember, you can post AM job opportunities for free on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com