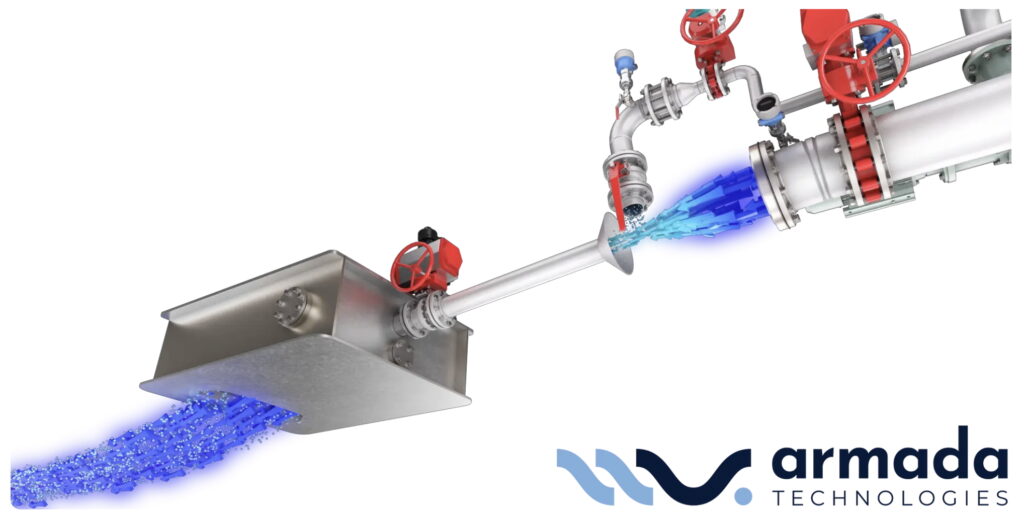

A Passive Air Lubrication System (PALS) a maritime efficiency technology used on ships to reduce frictional resistance between the hull and the surrounding water, which in turn cuts fuel consumption and emissions. It reduces drag by releasing microbubbles beneath a ship’s hull, creating an aerated layer that cuts fuel consumption and emissions.

Armada Technologies, a maritime and energy-efficiency company focused on shipping decarbonisation recently relied on additive manufacturing to produce an ejector for one of these systems.

This critical part features a precision geometry exposed to extreme pressures, corrosive seawater, and continuous flow), which poses a major manufacturing challenge. In general, traditional PALS rely on energy-hungry compressors. Armada’s design uses the vessel’s own forward motion to draw air through a proprietary venturi ejector.

To achieve the required internal features, surface uniformity, and environmental durability, Armada worked with 3D printing service bureau 3D People to manufacture its production parts. The components are produced using SLS 3D printing and PA12 Nylon, selected for its mechanical strength and durability, key requirements for this marine application. The parts are then finished using a vapour smoothing process, creating an optimal surface interface for the fluids flowing through them.

Over four production batches, every part met Armada’s tight timeline and quality thresholds. Eight months after installation, the components continue to operate flawlessly.

Over four production batches, every part met Armada’s tight timeline and quality thresholds. Eight months after installation, the components continue to operate flawlessly.

“3D People stood out immediately,” said Armada COO Roger Armson. “They understood the complexity of the part, grasped our technical needs quickly, and delivered prototypes that met our stringent functional and compliance requirements.”

Beyond the ejector, several other components of a Passive Air Lubrication System (PALS) are well suited to additive manufacturing—particularly where complex internal geometries, fluid control, corrosion resistance, and weight reduction are critical. These components may include air distribution manifolds, internal ducting and air channels, as well as protective housings and covers, among others.

It would be interesting to see how Armada continues to advance its additive manufacturing journey as the technology matures within its PALS development roadmap.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.