Remember when we told you that two critical factors drive efficiency in manufacturing: production throughput and workflow integration? Well this is not only the case for large-scale additive manufacturing, but also for other types of AM processes, including desktop FDM 3D printing.

Looking at production throughput specifically, the latest manufacturer who developed a solution that can improve the rate at which parts can be produced is AON3D.

According to the manufacturer, the standard approach to improve throughput has often failed because 3D printers rely on larger nozzles to achieve faster printing. This diminishes surface finish, and trial-and-error tuning — turning up print speeds, feed rates, and extrusion temperatures until quality begins to fail, then backing off slightly.

AON3D says these settings are applied globally, regardless of part size, geometry, and cooling conditions, treating every print the same. When applied to unique geometries, this one-size-fits-all approach often results in both drooping/poor surface finish, due to overheating, and unpredictable anisotropy due to variations in weld strength.

To address this issue, the Canadian company known for its high-performance 3D printers, has developed a software feature that utilizes physics-based G-CODE post-processing. The company claims that it was able to cut print times by as much as 54%, without compromising part quality or performance.

“Until now, polymer physics have been left out of the slicing process, relying solely on trial-and-error tuning — a time-consuming process with variable outcomes. AON3D’s Multiphysics Process Optimization changes this, achieving deterministic outcomes and tying predictions to results“, Adrian Muresan, AON3D VP Software Research, states.

How does it work precisely?

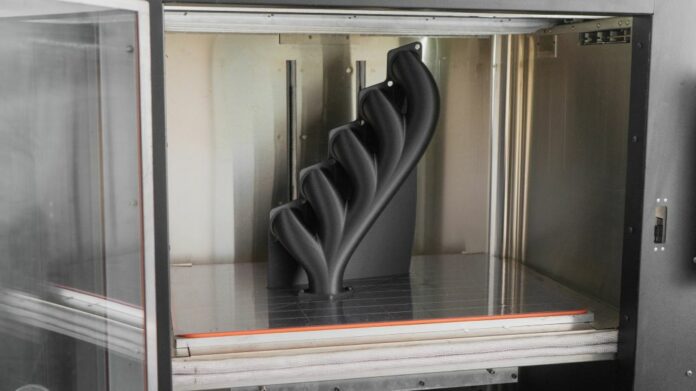

Utilizing a physics-based model of each polymer’s rheological and thermal properties, AON3D’s Throughput Optimization Module analyzes G-CODE to determine how heat will build and dissipate through a part. The software dynamically adjusts deposition rates based on part geometry to achieve the fastest possible print speeds without exceeding a material’s melt-fracture limits, and before inducing overheating deformation.

By coupling rheology and heat transfer properties, the system automatically accelerates when conditions allow and slows down when necessary to maintain surface finish. The result is maximum throughput without compromise: faster prints, consistent layer bonding, and smooth, repeatable parts every time — no trial and error required.

In testing, the software was able to cut 13 hours off a 24-hour print. AON3D’s new software feature is a large breakthrough for the utility of additive manufacturing for production applications.

On paper, this seems to be a reliable approach to increasing or ensuring throughput. In practice, what will AM users think? That’s the part we are waiting for to testify to the reliability of this software feature.

We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.