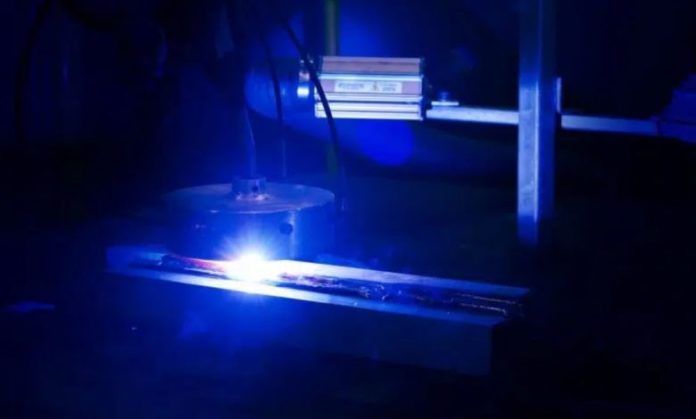

Metal 3D printer manufacturer AML3D Limited has signed an agreement with Deakin University’s Institute for Frontier Materials (IFM) to develop next generation materials and alloys specifically tailored to WAM® , the patented Wire Additive Manufacturing technology developed by the Australian manufacturer.

The announcement follows the recent establishment of AML3D’s facility at Tonsley’s ‘Factory of the Future’.

According to AML3D, a key focus will be made on optimising technology for high strength alloys, as wire feedstock for 3D printing and welding markets. Specific design of alloys that will deliver high strength wire coil for printing will be explored, as the ultimate goal is to remove any subsequent post-processing.

This will open up new markets and applications for WAM®, such as maintenance and repair tasks where WAM® can be directly applied to existing vehicles and structures (where a subsequent heat treatment might not be feasible).

Such exciting new technology to be developed from the partnership is anticipated to open new target industries and sectors for AML3D, supporting the geographical and sector based expansion of the Company. For example, AML3D and Deakin’s recent high strength aluminium – scandium wire feedstock project targets expansion into the marine, defence and aerospace sectors, with opportunities existing in the Asia Pacific (Japan, South Korea), European (Germany, France & the UK) and North American markets as well as creating opportunity for bespoke wire feedstock sales through specific IP and company branded consumables.

“The successful development of these alternative alloys provides significant potential upside for our business, not only through its application in WAM® and providing for other wire-fed DED processes, but the sales as a standalone feedstock product with widespread applications. The intended production of wire feedstock will provide an alternative within the general welding technology market that exceeds current applications. Whilst application through WAM® will provide customers greater flexibility in their choice of metal alloys, further enhancing the market leading position of our technology”, AML3D Managing Director Andrew Sales, states.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com