AM operators still spend too much time on manual, low‑value tasks that do little to improve output quality but significantly impact throughput, operator stress, and end‑of‑day workflows.

To address this challenge, AMIS, part of Hybrid Software Group, introduces an automation and scripting engine designed to eliminate repetitive build preparation tasks, reduce operator errors, and bring fully configurable, hands‑off workflows to industrial additive manufacturing.

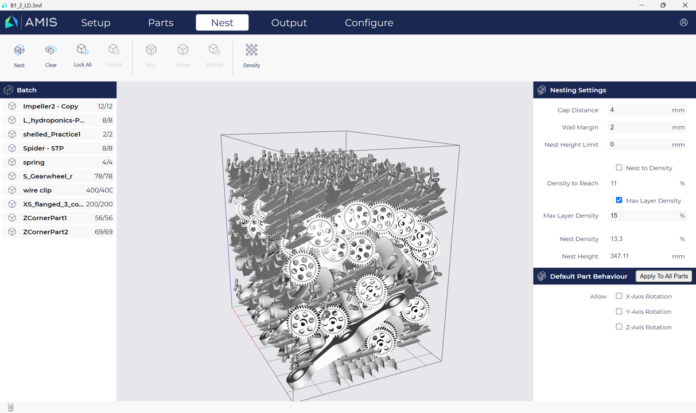

Named AMIS Runtime, AMIS claims that this software platform is the first to offer fully autonomous, continuously re‑nested build preparation.

Already deployed at two industrial production sites, the software platform helped early adopters refine the feature set based on real‑world bottlenecks and high‑volume production needs.

Key features of Runtime

AMIS Runtime automates the complete Build Preparation workflow, from part import to intelligent nesting to slicing and exporting, enabling AM operations to run consistent, configurable, and repeatable procedures across SLS, MJF, Binder and Material Jetting systems.

At the core of Runtime is a programmable approach to nesting and build preparation. Users can define part‑specific nesting behaviour based on size class, geometry, shell density, metadata flags, or business rules — allowing different part types to follow different optimisation strategies. This level of control enables highly efficient build creation that adapts dynamically to the part mix.

Runtime also supports continuous re‑nesting: as long as a build is not printing, it can be re‑evaluated and regenerated automatically when new parts arrive or priorities change. Parts and batches effectively behave as a virtual inventory, enabling flexible scheduling, higher utilisation, and just‑in‑time build preparation without manual intervention.

By automating these steps, Runtime gives teams the freedom to focus on value‑adding work such as machine management, quality inspection, and process optimisation.

“Build preparation drives both quality and economics in additive manufacturing,” says Kris Binon, Managing Director at AMIS. “By automating this step, AMIS Runtime helps users achieve better density, fewer errors, and smoother workflows, and that translates directly into lower cost per part and more predictable production. Early adopters already see the difference in day‑to‑day operations.”

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.