Gas flow might not be the flashiest topic in additive manufacturing, but it plays a quiet yet critical role in ensuring every layer is built with precision and consistency. While a few specialists offer technologies to keep the build environment clean and stable, customized AM systems—particularly those for large-format metal parts—often call for tailor-made solutions.

With that in mind, OEM AMCM introduces a dedicated gas flow system for its M 8K and upcoming M 10K printers. Named AirSwordTM, the gas flow management system combines “the unmatched speed and precision of fixed scanner systems with a fundamentally revised gas flow approach.”

It overcomes challenges often faced by traditional gas flow solutions in larger spaces where they often deliver uneven distribution, turbulence, and suboptimal outcomes.

Key features of the AirSwordTM

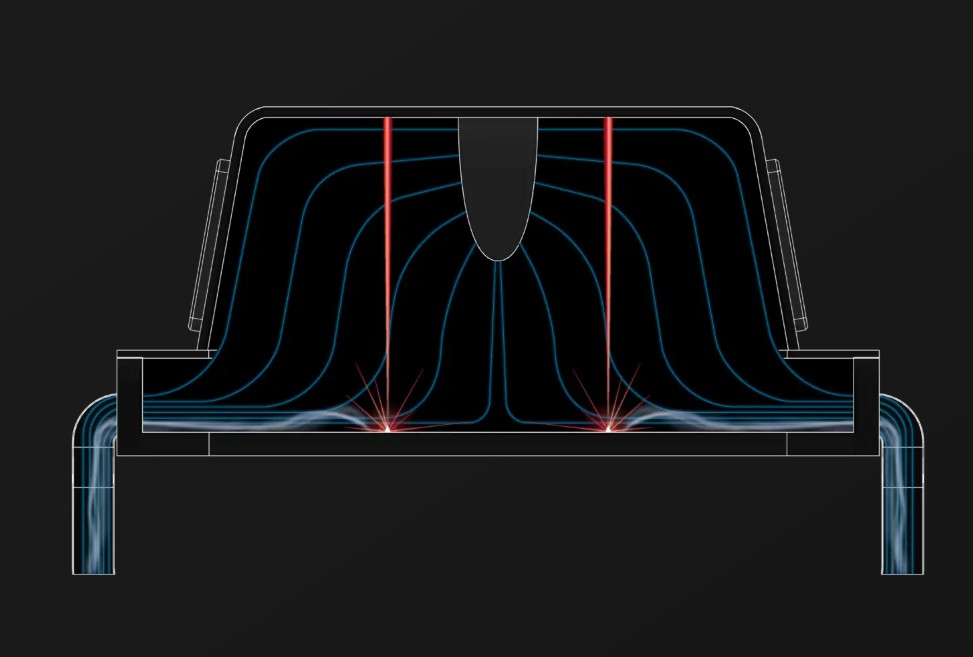

The AirSwordTM introduces a dynamic, multi-layered, and seamless gas flow that spans across the entire building area. This flow actively pushes smoke and soot directly toward the exhaust, maintaining optimal process conditions even in large chambers like those of the M 8K and the upcoming M 10K.

At the heart of the system is a central gas-emitting device that splits the flow into two opposing streams along the chamber’s axis. The key advantage of this design is that smoke from the simultaneously generated melt pools neither reaches the opposite side nor linger at the point of origin – eliminating any possibility of laser-smoke interaction. Instead, the smoke is extracted sideways for each half, ensuring a clean, interference-free process.

Another critical benefit of the AirSwordTM concept is its ability to keep cover glasses and the laser travel path free from smoke, a persistent challenge in long-duration LPBF print jobs. Accumulated soot and vapor plumes can degrade laser quality and part precision over time. AirSwordTM’s ceiling-directed stream efficiently clears the area in front of the optics, ensuring clear laser paths and consistent performance throughout extended builds.

“Designing a system of this size involves a whole range of challenges. The excellent laser, scanner, and optics design, based on decades of process expertise from EOS, ensures reliability. AirSwordTM complements this by maintaining a uniform protective gas atmosphere across the M 8K’s and M 10K’s expansive powder beds, safely dissipating fumes to avoid quality loss over long print times. Integrated with advanced process control technologies like SmartFusion and EOSTATE Exposure OT, AirSwordTM enhances in-process quality assurance, reducing the need for extensive post-build testing,” Martin Bullemer, Managing Director AMCM.

Featured image: AMCM GmbH _ Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media for free or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com