Last year, Headmade Materials, by developing the ColdMetal Fusion 3D printing process, joined forces with post-processing expert AM Solutions and research institute Neue Materialien Bayreuth, to launch the “AutoSmooth” project.

As a reminder, the project aimed to automate the Cold Metal Fusion process or CMF technology by automating the unpacking of 3D printed parts and subsequent surface processing. The three companies said they will unveil a system to improve green part processing next year.

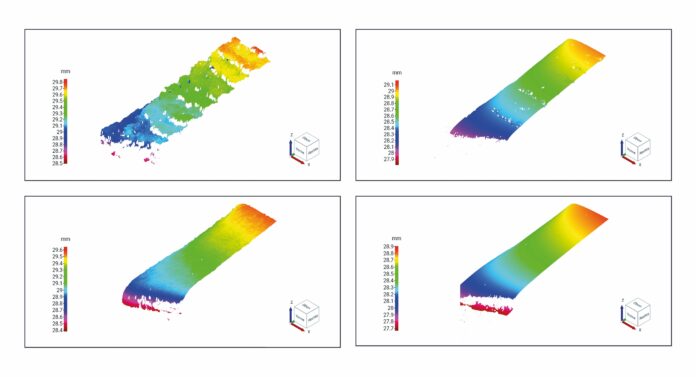

AM Solutions enhances green part processing with a shot blasting process that ensures part surfaces are depowdered finely and smoothed by a single process. The company explains in a press release that staircase effects are effectively removed, and the surface quality is already so high that in most applications there is no need for an additional, lengthy finishing process after sintering.

This saves an enormous amount of time. AM Solutions backs its tested 2-in-1 principle, merging the depowdering and smoothing steps in a single machine. Also, the powder is recovered using an advanced system and can be reused.

It results in cost-effective solutions by preserving valuable resources. A specialized part clamping solution ensures the precise handling of sensitive green parts over this process. It is crucial to understand that the CMF process is not a 3D printer but can ensure the creation of metal 3D-printed parts in series.

The major perk with CMF is that a standard and cost-effective powder bed-based polymer printer is suitable for printing. The parts made with CMF and such 3D printers don’t require support structures to be removed after printing. Unlike other binder-based processes, green parts made with CMF as part of the process are said to be significantly more stable, making the process more reliable.

The Division Manager at Rösler Oberflächentechnik GmbH, Dr. Till Merkel explains, “If we now provide the ‘missing link’ in post-processing with our new development, CMF technology will take a huge leap forward. This paves the way for cost-efficient, automated processes that completely unlock the potential of additive mass production for metal parts and significantly reduce unit costs.”

At the upcoming Formnext 2024 trade show, insights into the AutoSmooth project will be shared at AM Solutions’ booth in Hall 11.1, C41. Meanwhile, Headmade Materials will be found in Hall 11.1, Booth C51, and Neue Materialien Bayreuth in Hall 12.1, Booth C71.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.