Airwolf3D brings desktop printing even further with the announcement of its large format additive manufacturing system. Its credo is to enable users to “print even bigger” using industrial materials such as Hydrofill.

“We’re often asked what makes our machines different,“ said Airwolf 3D Co-Founder and CEO Erick Wolf. “All you really have to do is look at the type and quality of parts the EVO 22 is capable of manufacturing — large, real-scale parts that not only display beautiful print quality, but also exhibit the strength and mechanical properties required for functional prototypes and production-ready parts. Other machines in this price class simply don’t offer the same level of performance and quality, whether it is because their beds and hot ends fail to reach and sustain the temperatures required for pure, engineering-grade filament or they cut corners and use flimsy construction that, again, can not support advanced industrial desktop manufacturing.”

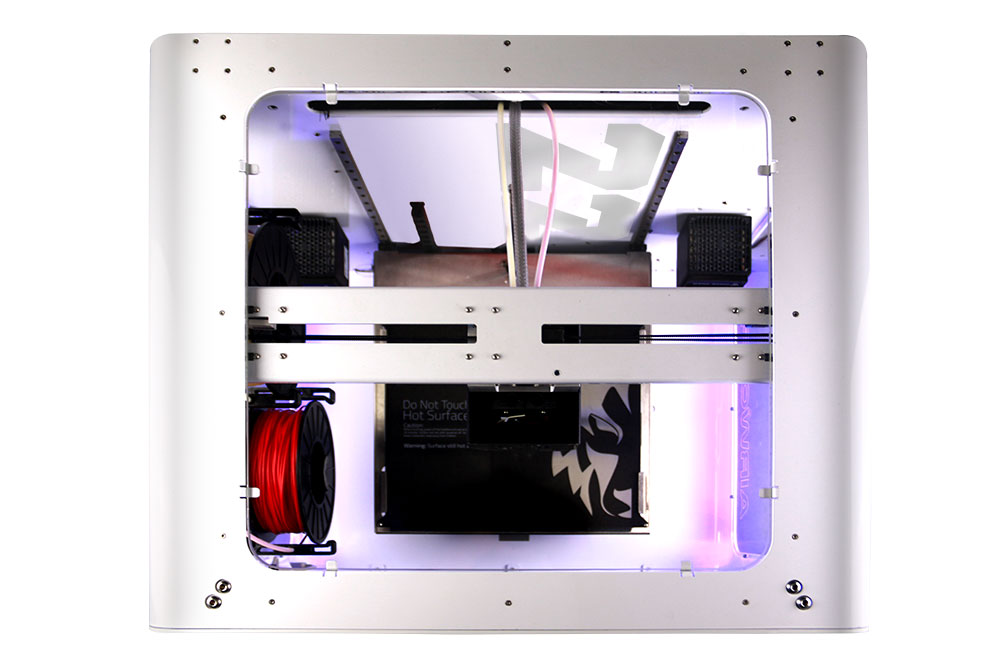

The EVO 22

The original EVO machine was launched at CES 2018 in January, the new EVO 22 is outfitted with a cartridge-style extruder assembly and a three-bolt-reinforced QuickChange hot end for faster, more precise extrusion of materials. The machine also integrates the EVO Series’ proprietary Tri-Heat™ Build Environment.

Comprised of two built-in chamber heaters and a high-temperature print bed, rated for 160 degrees Celsius, the Tri-Heat™ Build Environment gives users greater control over the machine’s internal ambient temperature, allowing them to create the ideal thermal environment for supporting large part production. Combined with a patent-pending hot end and enclosed chamber design, the TriHeat™ technology optimizes and regulates the heat needed to increase part strength while minimizing cracks and warpage.

The EVO 22 integrates Airwolf 3D’s firmware operating on the GENESIS board, a custom 32-bit automotive-grade microcontroller developed specifically for delivering a very good control at ultra-high temperatures. In addition, the EVO 22 ships with a HEPA and carbon air filtration system, patent-pending 100% aluminum unitized frame, one-piece stainless-steel bed frame, ball screw Z stage, and linear-guide-based CoreXY motion system.

For further information, follow us on our social media and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});