AGF Defcom, a company specializing in firearm manufacturing, including a turn-key barrel operation, acessories and everything in between, relies on metal 3D printing to produce suppressors.

The production is supported by the implementation of a “closed loop” upcycling program, in collaboration with material producer 6K Additive.

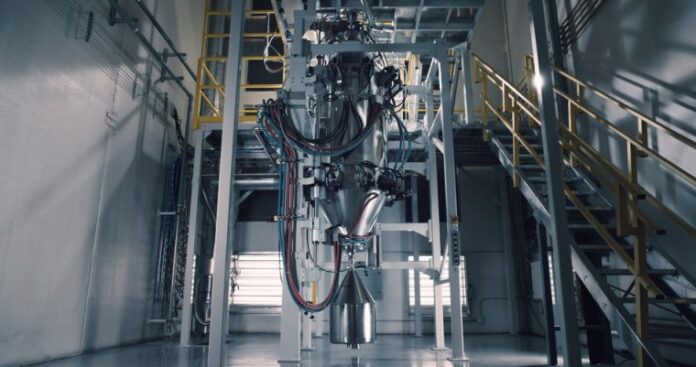

The idea would be to use 6K’s proprietary UniMelt® microwave production system, to transform the company’s manufacturing scrap, both solids and powder, into premium metal powder.

This initiative ensures a secure,100% domestic supply chain while significantly reducing material waste and production costs.

Zoltan Kovacs, owner and CEO of AGF Defcom said, “The suppressor market is accelerating at an unprecedented pace, and our investment in additive manufacturing is driving significant interest. To succeed with this technology, high-quality powder is a non-negotiable requirement. While partnering with 6K Additive ensures a premium domestic supply, the ability to upcycle our scrap is the real game changer. We have successfully transformed what was once a logistical and financial burden into a high-value asset that directly improves our bottom line.”

The suppressor industry has entered a period of explosive growth in 2026, primarily catalyzed by the removal of the $200 federal tax stamp. This regulatory shift has unleashed significant pent-up demand, leading to an unprecedented surge in applications and a diversified market for lower-priced consumer options.

Industry analysts have officially dubbed 2026 the “Year of the Suppressor,” forecasting record-breaking sales and a massive influx of first-time buyers. This high-volume environment creates a unique opening for advanced manufacturing techniques, particularly 3D printing, to scale production, even as the industry navigates potential fulfillment delays, a press release reads.

According to Additive Manufacturing Research’s Executive Vice President of Research Scott Dunham, suppressors are the latest market that will flip to an additive dominant production this decade. It’s therefore important for stakeholders to be able to continue to bring a solid value proposition in this area to accelerate the transition and push the AM industry forward as a whole.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.