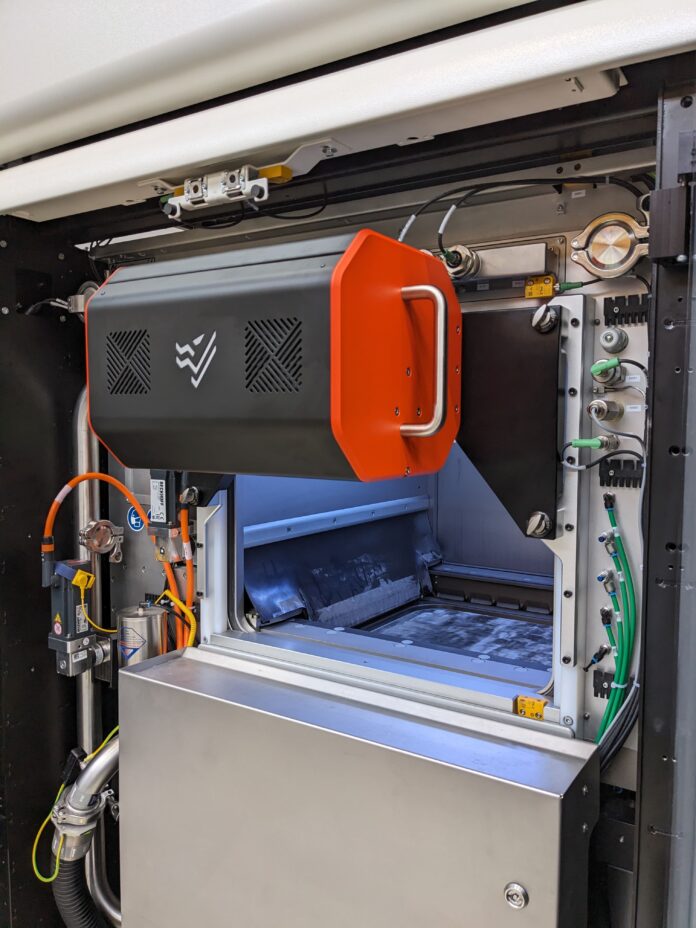

Additive Industries, a metal 3D printer manufacturer, teams up with Additive Assurance to drive quality assurance in Laser Powder Bed Fusion (L-PBF) 3D printers. It means Additive Assurance’s AMiRIS® in situ quality assurance solution will be integrated into Additive Industries’ MetalFAB machines.

The announcement follows the recent launch of the MetalFab 300 Flex 3D printer. Additive Industries, through its MetalFab series, delivers advanced automation and scalability to manufacture at a fast rate.

Along with increasing demands for increased production, there is also the challenge of producing items faithful to the original design.

AMiRIS® addresses this challenge by providing real-time insights during the build process. Any quality issues would be noticed immediately which can reduce cycle time, improve yield, and enhance trustability in the final product.

“Our partnership with Additive Assurance aligns perfectly with our commitment to advancing the abilities of metal Additive Manufacturing. By integrating AMiRIS® with our MetalFab portfolio, including our new MetalFab 300 Flex, we’re enhancing real-time quality assurance, offering our customers greater flexibility, and setting high standards in production consistency and reliability,” said Mark Massey, CEO at Additive Industries.

“We are delighted to be working with Additive Industries to add value to their customer’s experience and to push the boundaries of what is possible with L-PBF AM,” added Marten Jurg, CEO of Additive Assurance.

This partnership will increase the adoption of in situ process control for users of L-PBF machines and strengthen the role of AM in demanding industries such as aerospace, automotive, and energy.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.