Tungsten is one of those rare metals that is utilized for the production of hard materials such as tungsten carbide and other major alloys and steels. Due to its high ductile-brittle transition temperature, manufacturers usually favour spark plasma sintering, chemical vapor deposition, hot isostatic pressing, and thermoplastic routes to manufacture products with this material.

The material’s hardness and extremely high melting point have always made it difficult to process via additive manufacturing technologies. However, while many organizations are still exploring the capabilities of tungsten at the research level, one company is currently making tungsten-based 3D printing applications a reality: DUNLEE.

With Jan Philippe Grage, Product & Business Development Manager 3D Printing at DUNLEE as our guest, this Opinion of the Week discusses DUNLEE’s value proposition in the additive manufacturing industry and its specific focus on 3D printed tungsten parts.

A few words about DUNLEE

DUNLEE is acknowledged for a wide portfolio of imaging solutions in the industry. With a key focus on the medical industry, the company brings over a century of experience in the development and commercialisation of X-ray tubes, CT scanners, interventional radiography, diagnostic imaging, MRI component and nuclear medical imaging systems to various Original Equipment Manufacturers (OEMs).

During the past 50 years, the company has been operating in stealth mode in the additive manufacturing industry. “The last decade saw further developments of our efforts in the 3D printing industry. In 2007, we started investigating the type of solutions we could bring to this field of manufacturing. With our medical background and expertise of Computer Tomography (CT) solutions, we explored AM to support the expansion of our CT portfolio. Thereafter, we came to realize that among the materials that could be utilized in the industry but that were not, tungsten offered a great potential. Our R&D team started exploring the type of applications we could achieve using additive manufacturing hence the focus on 3D printed tungsten products today”, Grage explains.

What makes tungsten an interesting yet challenging material for additive manufacturing?

As a robust material, the behaviour of pure tungsten powder needs to be thoroughly mastered in order to enable the production of high-density parts.

A recent study reveals that a strategy for fabricating high-density parts can be developed by creating a process map in which the effect of laser energy density is studied. The process quality might therefore require the use of different techniques including light optical microscopy, XCT, SEM and EBSD; the ultimate goal being to reach a point where the laser energy density is adequate to process tungsten and makes it viable for the production of functional parts.

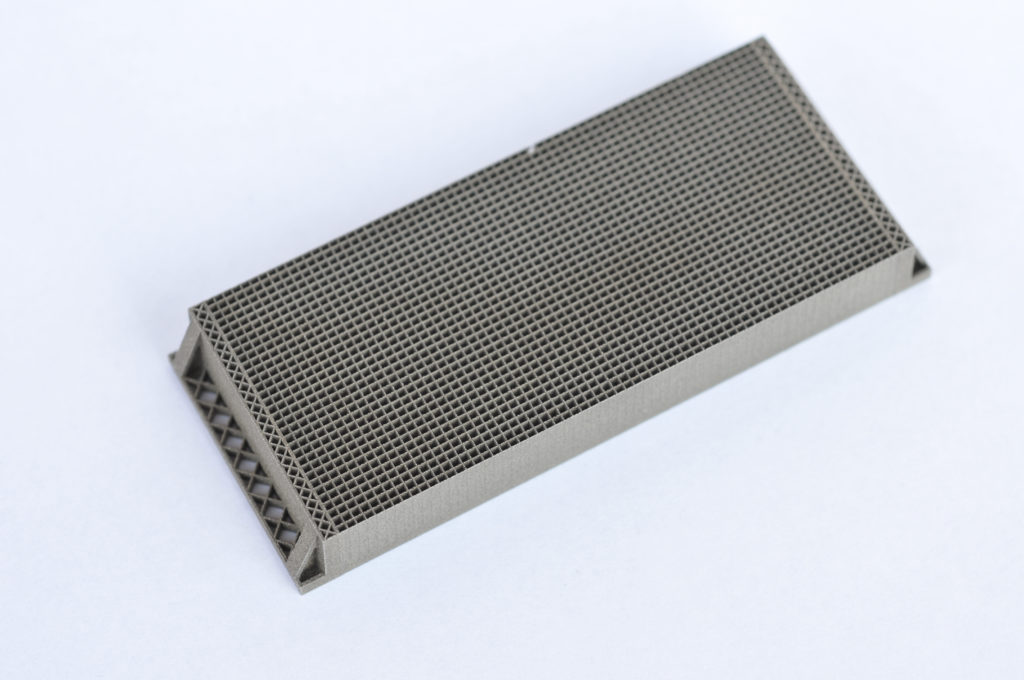

By taking directly an application as example, Grage explains that anti-scatter grids (ASG) are crucial components in CT scanners as they absorb scattered radiation and increase image quality. Tungsten is the ideal material to produce these anti-scatter grids for several reasons: in addition to its high melting point and high density, the material delivers the highest tensile strength at high temperatures and provides good resistance to most acids. It is biocompatible, non-toxic and can withstand corrosion. Furthermore, even though the following feature is not the main one that characterizes its utilization for CT systems, it is worth noting that tungsten also has the ability to withstand very high temperatures (3422°C) – which makes it interesting for other applications.

“There were already solutions for what we produce today but traditional manufacturing does not allow this fine manufacturing that is very much needed for tungsten parts. Grids are very small components that sit on top of a detector within a CT system. When the X-rays are shot through the patient, some of these X-rays are scattered and are absorbed by the ASG walls. Only the x-rays that are not scattered are allowed to pass through and make the high-resolution image in the end. With ASG produced with our pure tungsten AM, we found out that they have the best characteristics to absorb X-rays. With AM, we are able to achieve highly detailed and thin parts with details as small as 100 μm and they are all focused towards the X-ray source – [In other terms, X-rays can now be directed into the photodiode with higher precision]. This is the primary reason why we started investigating AM”, the Product & Business Development Manager told us.

As far as manufacturing is concerned, the expert mentioned that their collaboration with EOS leads to the development of a dedicated solution to 3D print tungsten parts.

**Interestingly, a recent interview with AMCM’s experts Felix Bauer and Martin Bullemer also confirms the need for a solution-oriented partnership to manufacture 3D printed tungsten parts. Reality shows that Selective Laser Melting or Direct Metal Laser Sintering (DMLS) as well as Binder Jetting are currently the two types of AM technologies that can process pure tungsten and other tungsten-based alloys.

As it turns out, DUNLEE has first collaborated with EOS on the manufacture of 3D printed tungsten parts. Thereafter, to meet the requirements in terms of resolution and accuracy for the production of 3D printed tungsten parts, AMCM, Dunlee and EOS worked on the development of a customized industrial 3D printer for this application.

“All AM technologies do not have the capabilities to 3D print this material. The 3D printer needs to be customized to allow smooth process and the post-processing step needs to be done very carefully to achieve very functional parts. In such manufacturing of tungsten parts, DUNLEE really distinguishes itself thanks to post-processing. That is what makes us unique”, the Product & Business Development Manager outlines.

Due to intellectual property reasons, further details could not be given on the way DUNLEE post-processes tungsten parts.

However, according to EOS’ Felix Bauer, the recent year highlighted the importance of CT imaging as a valuable tool in the fight against Covid-19 as it can easily detect the “ground glass” white spots in the lungs that are a sign of the virus. To keep pace with CT manufacturers’ demand for the anti-scatter grids, Dunlee has doubled its production capacity with the help of AMCM GmbH and is now ready to mass produce these medical components.

Other applications

While we learned that the healthcare industry uses pure tungsten for MRI scanning, and anti-scatter grids (ASG), a wide range of applications can be explored with 3D printed tungsten.

“Applications with 3D printed tungsten are so dense. The counterweight requirement and the density that can fill the most weight per area make it a good candidate for a plethora of applications from automotive, space all the way to energy”, Grage notes.

Tungsten might be a very delicate material to process at the manufacturing level, but its increasing interest within the manufacturing field shows it is a valuable one.

On this day, February 3rd, EOS and DUNLEE will provide further insights into the additive manufacturing of 3D printed tungsten parts during a webinar.

**Disclosure: the interview with AMCM GbmH, an EOS company, will be featured in the upcoming January/February Issue of 3D ADEPT Mag.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com