In May 2025, the team was awarded a one-year, $1.4 million grant that is contingent on meeting certain benchmarks, with five other teams competing to do the same.

With the goal of improving on-site maritime construction and the repair of critical infrastructure that connects continents, an interdisciplinary group of Cornell researchers is developing a way to bring concrete 3D printing to the ocean.

“We want to be constructing without being disruptive,” said Sriramya Nair, assistant professor of civil and environmental engineering in the David A. Duffield College of Engineering, who leads the effort. “If you have a remotely operated underwater vehicle that shows up on site with minimal disturbance to the ocean, then there is a way to build smarter and not continue the same practices that we do on the land.”

The complexity of underwater 3D printing requires a range of specialized knowledge, so Nair assembled an interdisciplinary group with two sub-teams, one for material design, the other fabrication.

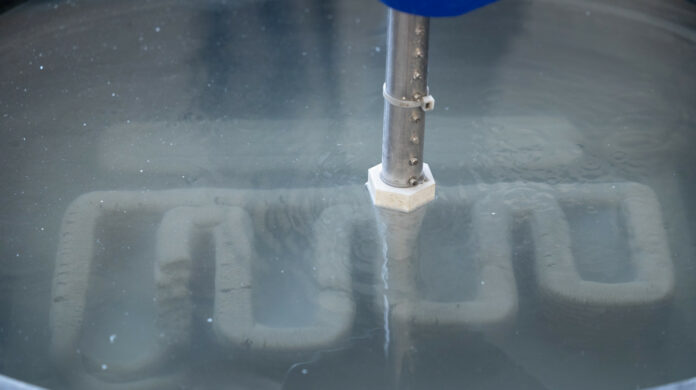

When the call for proposals was issued, Nair explained that his team decided to move forward simply to understand the challenges, and discovered that, with their existing concrete mixture and some adjustments to account for continuous water exposure, they could successfully 3D-print underwater using their roughly 6,000-pound industrial robot.

Underwater printing faces numerous challenges such as:

- Preventing washout while maintaining printability:

Underwater deposition risks washout, where cement particles disperse before binding, weakening the structure. Anti-washout admixtures can solve this, but they increase viscosity, making the concrete difficult to pump and complicating the balance between flow, shape retention, and interlayer bonding.

- Formulating concrete with minimal cement content:

A key constraint was the requirement to use mostly seafloor sediment with only a small amount of cement, reducing the need to transport materials offshore but adding complexity to mixture design and structural performance.

Rather than sending scuba divers under the water, the fabrication team set out to design sensors that can track the printing as it occurs. They developed a control box with multiple sensing systems that can be integrated with the robot arm, paired with advanced robotics capabilities to enable greater autonomy and control in underwater concrete printing.

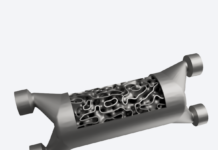

The DARPA competition’s final demonstration will be held in March, and the team is racing to incorporate the advances made by the fabrication team with those of the materials team to successfully print the arches.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.