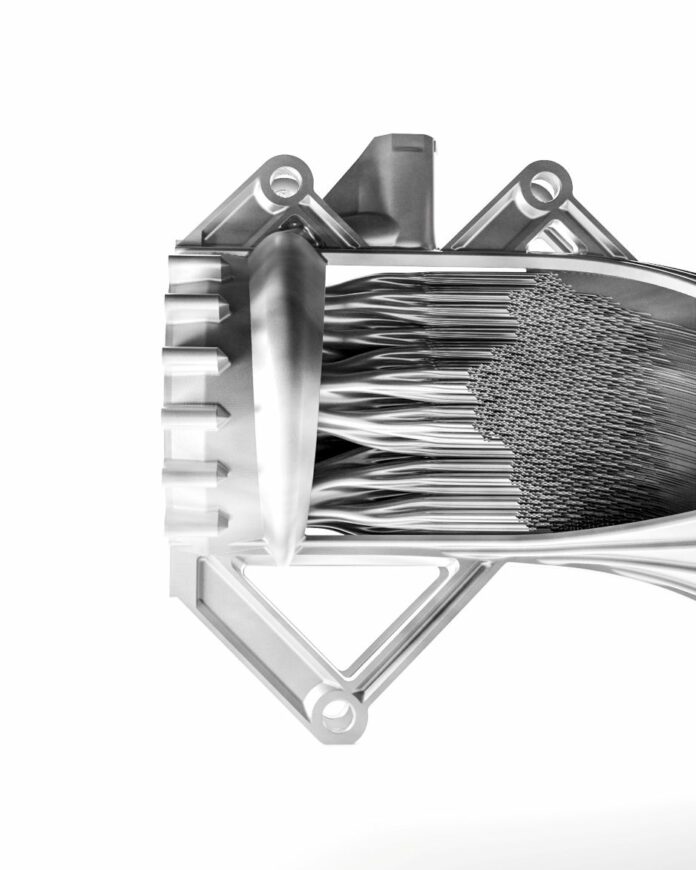

Following the launch of its most ambitious rocket engine, LEAP 71 unveils a 1.5 m hypersonic precooler concept. Developed in collaboration with OEM Farsoon Technologies, this component would be a key enabler for air-breathing launch vehicles.

The part highlights the capabilities of the now-famous Noyron system and how it constantly grows in capability with every insight gained from designing and manufacturing highly elaborate machinery.

Manufactured on Farsoon’s large metal 3D printer, the FS811M-U-8, the component addresses extreme thermal challenges in hypersonic flight. “At hypersonic speeds, incoming air can reach several thousand kelvins due to stagnation effects,” said Josefine Lissner, Managing Director of LEAP 71 and Principal Architect of Noyron. “To manage these temperatures, we implemented a fractal folding algorithm in Noyron, maximizing surface area without compromising aerodynamic flow. The intertwined structure separates the superheated air from the liquid-hydrogen coolant, enabling rapid thermal exchange in a compact, manufacturable form.”

According to Lin Kayser, cofounder of LEAP 71, the long-standing vision of winged spacecraft has depended on propulsion systems that can operate in the atmosphere at hypersonic speeds before switching to rocket mode. Advances in Computational Engineering, combined with large-scale metal additive manufacturing, now offer a real opportunity to overcome some of the key technical barriers that have held back this concept.

“This collaboration demonstrates how the convergence of large-format metal additive manufacturing and AI-driven design can redefine the limits of aerospace engineering,” said Oliver Li, General Manager, Farsoon Europe GmbH. “Farsoon’s open, industrial-scale LPBF systems empower partners like LEAP 71 to transform digital intelligence into tangible high-performance components — proving that innovation and collaboration are the true engines driving the next generation of space technology.”

The two companies aim to reignite the discussion about reusable spacecraft and broaden the focus toward alternatives to today’s vertical takeoff and landing paradigm. The finished precooler will be exhibited at Formnext 2025 in Frankfurt at the Farsoon booth (Hall 11.0, Booth E11).

We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter