In May, computational engineering expert LEAP71 announces its rocket engine program which aimed at scaling its computational engineering methodology. What was supposed to last at least one year before the first reveal took a few months to build as the company announced yesterday the XRB-2E6, a 2 Meganewton full-flow-staged-combustion Methane/LOX engine.

The large-scale metal part was printed using the high-speed SLM NXG 600E industrial additive manufacturing system and marks an important milestone in a collaboration that began more than two years ago.

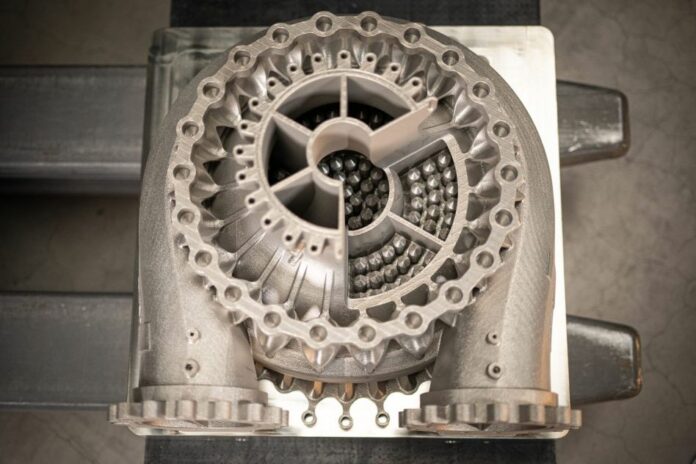

This critical part of the LEAP 71 XRB-2E6 methane/liquid oxygen rocket engine features 600 mm in diameter and was generated entirely by LEAP 71’s Noyron Large Computational Engineering Model.

This physics-driven software system described as “the first AI that builds machines,” operates entirely without human intervention.

The part manufacturing

Christoph Wangenheim, Head of Additive Material Products & Development at Nikon SLM Solutions explains: “When LEAP 71 came to us to discuss the production of a key element of one of the world’s most advanced space propulsion systems, we knew it would be a challenge we couldn’t resist. We worked closely with LEAP 71 on incorporating essential manufacturing parameters into their Noyron system and fine-tuning the interplay between the steps of the process chain. As a result, we were able to not only print the intricate structure reliably on the NXG 600E, but also in the record time of four days — key to making production economically viable and enabling rapid iteration during qualification.”

The part was produced in Inconel 718, an aerospace-grade nickel alloy engineered to endure the extreme heat and pressure conditions of a full-flow staged combustion (FFSC) engine cycle. Often described as the holy grail of rocket propulsion, FFSC is the most efficient method for converting a propellant’s chemical energy into thrust. However, this advanced engine cycle also presents significant challenges, as it requires managing hot, pre-combusted methane and oxygen flowing through a highly intricate injection system.

This functionally integrated part requires no assembly and can be transferred directly to the test stand with minimal post-processing. This approach aligns with LEAP 71’s philosophy of fast and frequent practical testing, enabling the Noyron system to be continuously enriched with real-world insights.

The XRB-2E6 system serves as a reference design, with customer-specific engines computationally derived to meet varying target specifications. Through this approach, LEAP 71 collaborates with leading global companies to accelerate humanity’s access to space.