In high-performance cars, manufacturers leverage the flexibility and precision of Additive Manufacturing (AM) to push the boundaries of performance, efficiency, and customization. From engine components to aerodynamic elements, this approach addresses technical challenges while reducing development time and costs. The article below discusses the use of AM in high-performance cars, as well as the challenges and limitations that pertain to this niche segment.

What is High-Performance Automotive?

High-performance automotive refers to vehicles designed to deliver exceptional levels of power, speed, acceleration, handling, and technical precision. These vehicles, often from prestigious brands like Ferrari, Lamborghini, or Bugatti, include both sports cars and competition vehicles such as those used in Formula 1 or endurance racing.

These models are often equipped with the latest advancements in engine technology, aerodynamics, and lightweight materials, with a particular emphasis on pure performance and driving experience. Their design demands extreme precision, making the integration of technologies like Additive Manufacturing particularly relevant.

Additive Manufacturing (AM) in the automotive sector: Key facts

In the automotive sector, manufacturers initially used AM to produce prototypes of complex parts at lower costs and in shorter timelines. More recently, Additive Manufacturing has become an indispensable tool for producing components for high-performance vehicles.

The low production volume of Additive Manufacturing currently prevents its adoption in mass production. However, for motorsports like Formula 1, which does not require mass production, Additive Manufacturing is an ideal solution. Formula 1 teams work on only two vehicles per season, and given the rapid iteration required during development, it is no surprise that Additive Manufacturing has been widely adopted across engineering teams within this sector.

Additive Manufacturing in Formula 1: A Strategic Application

In Formula 1, Additive Manufacturing plays a critical role in meeting the demands for performance, innovation, and responsiveness. Here’s how it is used in this elite field:

- Rapid prototyping and accelerated development: Teams use Additive Manufacturing to quickly create prototypes of complex parts, enabling them to test multiple variants in wind tunnels or simulators within days. This significantly reduces the time between design and validation.

- Manufacturing functional parts: Some 3D-printed parts are directly integrated into race cars, such as:

- Cooling ducts: Designed to optimize airflow and maintain optimal temperatures.

- Aerodynamic components: Custom deflectors or ducts printed to meet circuit-specific requirements.

- Lightweight mounts and fixtures: Made from reinforced polymers or metal, reducing the car’s overall weight.

- On-site production: Some teams bring 3D printers to their paddocks to produce parts directly at race locations. This allows for replacing or adjusting components in record time.

- Wind tunnel testing: Scale models printed in 3D are used to experiment with aerodynamic concepts before applying them to full-scale cars.

Teams like Mercedes-AMG Petronas, Red Bull Racing, or McLaren have adopted these practices to maximize performance and continuously innovate.

The most widely used technologies in this sector include stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM). Each offers specific advantages in terms of precision, production time, and material choice.

Advantages of 3D-Printed Parts in High Performance cars

The growing interest in Additive Manufacturing in high-performance automotive is based on several key advantages you have probably already seen in other applications:

- Lightweight design and material optimization Additive Manufacturing enables the creation of complex structures, such as honeycomb patterns, that reduce weight while maintaining high mechanical strength. The result: lighter vehicles, leading to improved performance and reduced energy consumption.

- Custom design and personalization Additive Manufacturing allows for creating unique parts tailored to specific needs. For race car or luxury vehicle manufacturers, this customization is a major asset.

- Cost and time reduction Unlike traditional methods that often require expensive molds and long production times, Additive Manufacturing can directly produce a part in just a few hours.

- Rapid prototyping and innovation Design teams can quickly iterate and test different designs, accelerating the innovation cycle.

Materials Used in Additive Manufacturing for High-Performance cars

In high-performance automotive, materials used in Additive Manufacturing are selected for their lightweight properties, strength, and ability to withstand extreme conditions:

- Metal alloys

- Titanium: Lightweight, corrosion-resistant, and capable of withstanding high temperatures. Ideal for parts like brake calipers or engine components.

- Aluminum: Used for lightweight parts requiring good thermal conductivity, such as radiators or support structures.

- Inconel: A nickel-based alloy used in applications exposed to very high temperatures, including exhaust systems or turbine parts.

- Advanced polymers

- PEEK (Polyetheretherketone): Resistant to high temperatures, chemicals, and wear. Used for lightweight structural parts in engine compartments.

- Reinforced nylon (with carbon or glass fibers): Offers high mechanical strength while remaining lightweight, ideal for aerodynamic components or technical mounts.

- Polycarbonate (PC): Used for applications requiring transparency, robustness, and impact resistance.

- Composites

- Carbon fiber-reinforced materials: Widely used for elements like fairings, air ducts, or chassis mounts. They combine exceptional rigidity with lightweight properties.

- Technical ceramics: Although less common, 3D-printed ceramics are sometimes used for components exposed to extreme heat or corrosion, such as seals or thermal shields.

- Prototype-specific materials: For rapid prototyping, plastic materials like PLA or ABS can be used, although they are generally unsuitable for final applications in high performance.

These materials allow manufacturers to design parts that meet the industry’s strict requirements while optimizing vehicle performance.

Concrete Applications in High-Performance Vehicles

Several manufacturers have integrated Additive Manufacturing into their production processes. Here are some notable examples:

- In 2018, Bugatti showcased for the first time 3D-printed titanium brake calipers, combining strength and lightness. These components are subjected to extreme stresses while ensuring optimal performance.

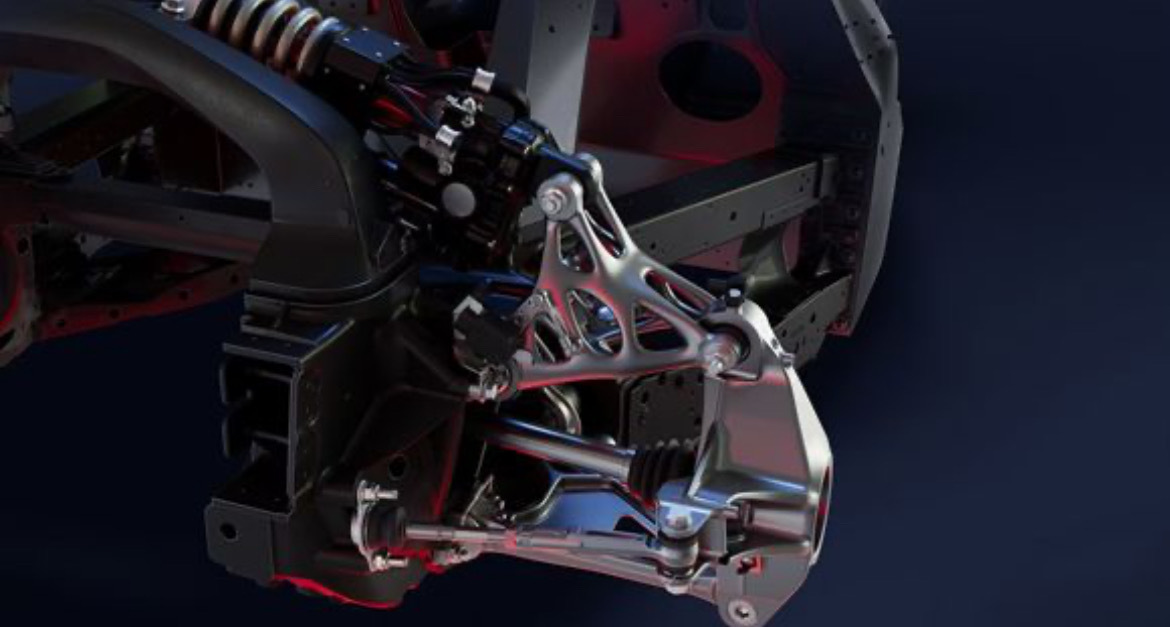

Following this, in 2024, for the development of its latest hypercar, the Bugatti Tourbillon, the French manufacturer partnered with the American company Divergent Technologies, Inc (Divergent), which develops an end-to-end hardware and software production system for industrial digital manufacturing. This partnership enabled the use of the Divergent Adaptive Production System (DAPS™) to design, manufacture additively, and assemble chassis and suspension components. Divergent’s end-to-end digital approach to vehicle design and manufacturing allowed Bugatti to propose more efficient geometries for the vehicle chassis, significantly reducing the vehicle’s weight and improving its performance.

- In April 2020, Porsche introduced 3D-printed pistons, parts for the high-performance engine of the most powerful Porsche 911 (the Porsche 911 GT2 RS), reducing their weight and improving engine efficiency.

Using the laser metal fusion (LMF) process for piston manufacturing, a closed cooling channel was integrated into the base of the 3D-printed pistons—an operation impossible with material removal processes. This intricate channel reduces the thermal load on the piston rings by 20°C. The 3D-printed pistons are stiffer and 10% lighter than traditionally produced components. Thanks to these pistons, the engine’s RPM could be increased, and combustion optimized.

Result: up to 30 additional horsepower and improved efficiency. During quality control, the 3D-printed pistons successfully underwent a 200-hour endurance test on the engine test bench.

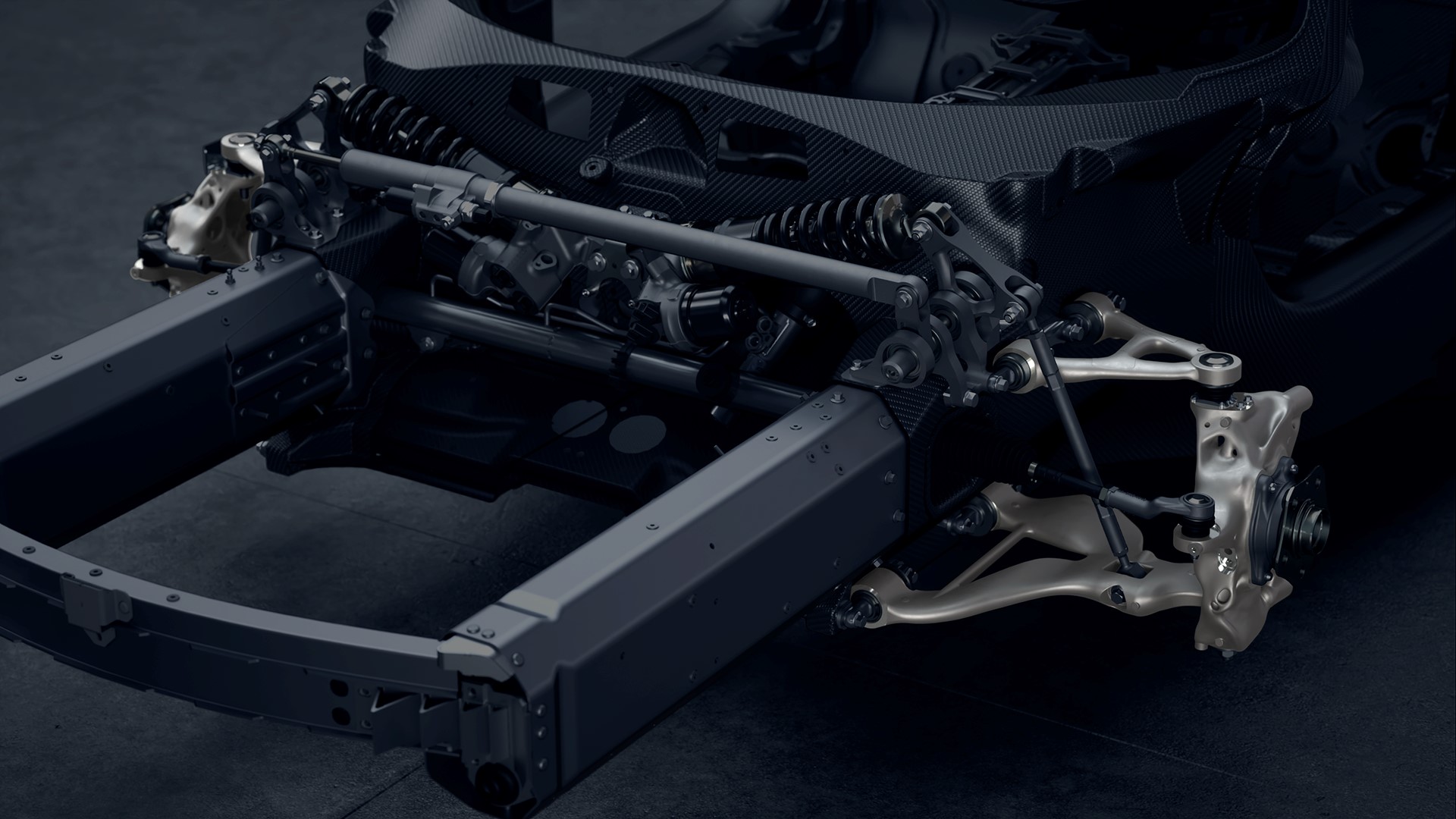

- In 2024, Ferrari equipped its latest supercar, the F80, with additively manufactured structural components for the first time. The F80’s independent suspension includes a double wishbone configuration, active internal dampers, and suspension arms created via additive manufacturing.

The Italian manufacturer used metal Additive Manufacturing to produce essential components, leveraging its experience in motorsport, notably Formula 1. Technologies initially developed for racing cars, where performance is finely tuned, are now integrated into road cars like the F80.

This solution offers numerous benefits, such as optimized configurations, more precise wheel control, reduced unsprung mass, the absence of an anti-roll bar, and the introduction of a dedicated camber angle correction function.

This system meets two seemingly contradictory requirements: on one hand, the need for flat handling on track, where height variations must be minimized, and on the other hand, the need for flexibility to absorb road irregularities during regular driving. This means the car offers excellent handling on the road while also managing downforce optimally in all conditions.

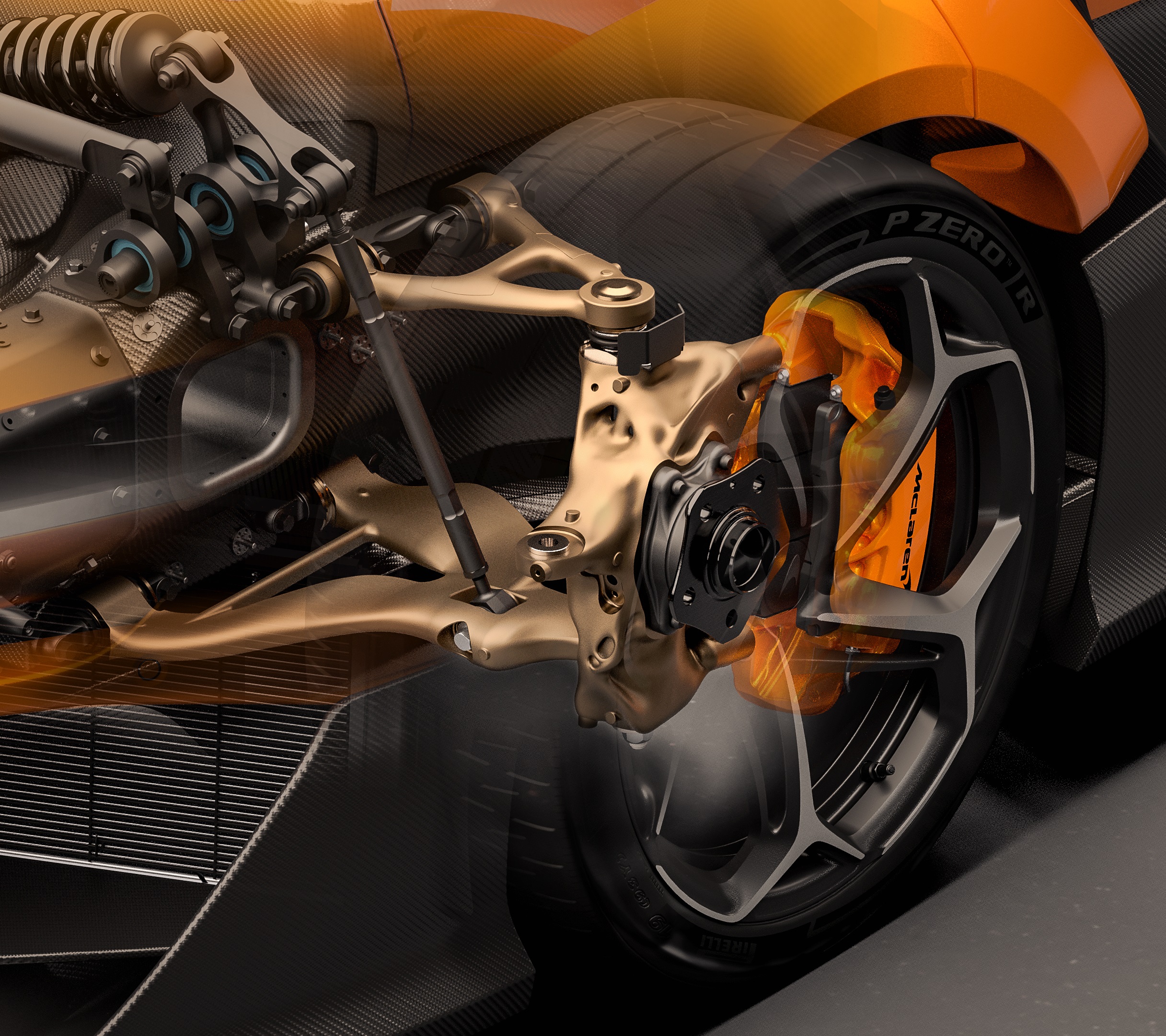

- McLaren Automotive partnered with the Californian digital industrial manufacturing company Divergent Technologies, Inc (Divergent) to supply advanced suspension hardware designed and manufactured for its latest supercar, the McLaren W1. The new McLaren W1 is equipped with a Formula 1-inspired front suspension mounted directly into the Aerocell carbon fiber monocoque.

Divergent’s additive manufacturing technology helped McLaren develop efficient and complex suspension systems for optimal durability and rigidity, including the upper front triangle, the aerodynamically shaped lower triangle, and the front mount for McLaren’s latest supercar. The visible front triangles are key 3D-printed components by Divergent.

The company’s innovative design and manufacturing methods allowed McLaren’s engineers to quickly iterate designs to advance the development of the revolutionary structural suspension components of the supercar, contributing to the W1 vehicle’s superior performance and driver engagement.

“We are thrilled to have partnered with Divergent, a company that shares McLaren’s commitment to innovation in manufacturing and engineering. This cutting-edge technology has allowed us to develop more complex suspension structures in the McLaren W1, which enhance the driving experience for our customers and support McLaren’s mission to continuously push the boundaries of performance.” Michael Leiters, CEO, McLaren Automotive

Many more application cases in high-performance vehicles exist beyond those presented in this article. After a global analysis of these applications, it is clear that they largely involve the design and additive manufacturing of specific components. While they illustrate how Additive Manufacturing meets extreme performance and durability demands, one cannot help but question the limits hindering a broader and more widespread use of this technology throughout the entire design and manufacturing process of high-performance vehicles.

Future Prospects

Although Additive Manufacturing offers significant environmental benefits for high-performance automobiles, its large-scale adoption for mass-market vehicles raises economic questions. Key challenges include:

1-n Cost of equipment and materials

Industrial 3D printers capable of producing complex metal or polymer parts require significant upfront investment. Moreover, durable, recyclable materials can be more expensive than traditional equivalents.

2- Small-series production

Additive Manufacturing is particularly effective for small-series or unique parts. However, for producing millions of vehicles for the mass market, traditional methods like molding or stamping remain more cost-effective.

3- Cost reduction over time

Despite high initial investments, Additive Manufacturing could enable long-term savings by reducing waste, limiting transport needs, and promoting circular economy principles.

4- Potential economies of scale

As the technology becomes more widespread and demand increases, the costs of 3D printing materials and equipment are expected to decrease.

Current Challenges and Limitations

1- High Costs

The equipment and materials used, such as special alloys or advanced polymers, remain expensive. This limits its adoption for mass-market vehicles, where margins are thinner.

2- Production Time

While Additive Manufacturing is fast for prototypes or small series, it remains slow compared to traditional processes, like molding or stamping, which can produce thousands of parts in record time.

3- Production Capacity

Current 3D printers still cannot compete with automated production lines in terms of volume, which hinders its large-scale use.

4- Durability and Reliability

Some 3D printed parts still need to prove their resistance and performance under prolonged use, especially for vehicles designed for daily use.

5- Certification Standards

In mass-produced vehicles, each part must meet strict standards of quality, safety, and performance. Printed parts still require rigorous certifications to ensure compliance.

6- Integration into Existing Production Lines

Integrating Additive Manufacturing into traditional industrial processes would require significant investments to adapt or rethink infrastructures.

Conclusion

Additive Manufacturing, although still limited to specific applications in high-performance automobiles, is gradually establishing itself as a catalyst for innovation. It allows manufacturers to push the boundaries of what’s possible, whether it’s weight reduction, custom design, or accelerating development cycles.

However, for this revolution to move from an elite tool to an industry standard, obstacles remain, particularly in terms of cost, production speed, and integration into traditional processes.

In the near future, it’s not unrealistic to imagine a hypercar entirely designed using Additive Manufacturing: from the chassis to the bodywork, to the engine and its smallest components. This project, which seemed unachievable a decade ago, is becoming a reality as the industry perfects its processes.

If industry players continue to overcome the current challenges, it’s only a matter of time before a fully 3D-printed car hits the road, marking the beginning of a new era for the automotive industry.