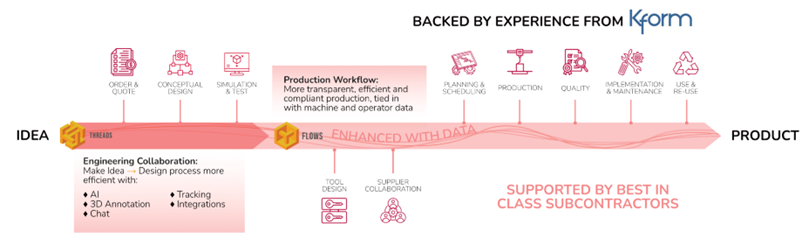

CHOPS aims to replace siloed engineering with live, traceable delivery from idea to part.

Authentise, an expert in digital manufacturing workflow software, joins forces with Kform, an agile engineering and defense-grade manufacturing provider, to launch Project DDNA, the first operational implementation of a new delivery model: Continuous Hardware Ops (CHOPS).

Designed for defense programs – and already in use by the U.S DoD, the system allows engineering teams to accelerate development timelines, maintain context throughout design iterations, and automatically produce audit-ready, AI-readable outputs. Described as a new category by both companies, it breaks from outdated, siloed, linear engineering methods.

Department of Defense customers currently use it to deliver parts for the world’s largest wind tunnel and re-engineered field-ready wearables in under eight weeks.

“Our first prime contracts in reverse engineering made it brutally obvious,” said Andre Wegner, CEO of Authentise. “Every project starts from zero because none of the prior decisions—why that material, that geometry, that process—are ever captured. DDNA changes that. It builds context into the process, so we stop relearning what we already knew.”

Why CHOPS, why now?

Why CHOPS, why now?

Today’s defense programs are bogged down by fragmented workflows, missing context, and a culture of reactive quality assurance. Projects restart at every phase. Reverse engineering often means starting from scratch. And traceability dies the moment a decision leaves a meeting or email.

“We’re not pitching a product,” said Callye Keen, CEO of Kform. “This is a new category. It connects engineering, manufacturing, and quality assurance in real time. It’s what lets small teams move fast, scaled up for the biggest problems in defense.”

With DDNA, every conversation, assumption, and decision is captured and linked to the final part. The system integrates with MBSE, CAD, MES, PLM, and ERP platforms, and generates audit-ready, AI-readable outputs by default, a press communication reads.

Authentise and Kform are now working with early adopters to bring CHOPS to more DoD programs. Whether launching new systems, scaling production, or modernizing legacy parts, CHOPS delivers speed with traceability—and persistent readiness across the supply chain.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.