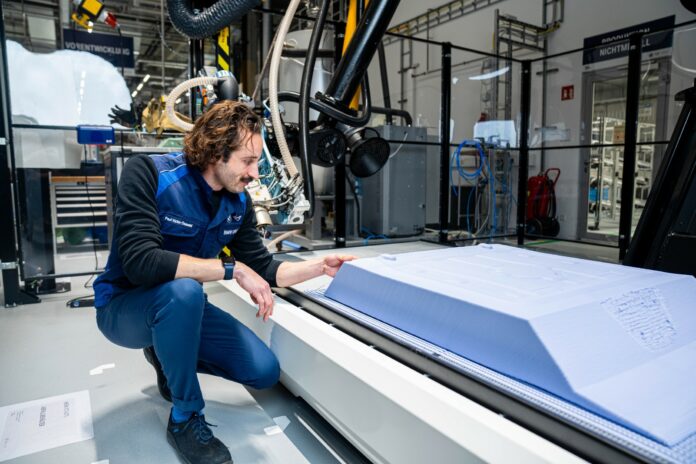

In 2018, BMW Group started the “bottleUP” project, which focused on obtaining 3D printing material for various applications by recycling PET bottles. A year after the project launch, the first industrial waste was being used to produce recycled filament on a pilot basis. The team led by Paul Victor Osswald, project manager for Predevelopment Non-Metals, 3D printed the first holders and auxiliary production devices using their own recycled filament by 2021.

Fast forward to today

Today, various locations across the BMW Group’s global production network are supplied with 3D-printed components from the Additive Manufacturing Campus in Oberschleißheim, where the company has consolidated its production, research and training activities in additive manufacturing under one roof.

Each year, up to 12 tonnes of waste powder can be recycled into filament and granulate and can then be reused for the manufacture of auxiliary production devices in the plants and for pre-development projects at the Additive Manufacturing Campus.

“I’ve been involved with this project from the very beginning and I’m thrilled to see how far we’ve come – from our initial ideas and attempts at startup level to now being able to produce large quantities of highly robust components from recycled filament at any BMW Group production location. It’s incredibly exciting to continuously develop and test new processes. The use of waste powder and discarded 3D printing components is a key element of a functional and efficient circular economy,” says Paul Victor Osswald, project manager for Predevelopment Non-Metals.

Recycling process and applications

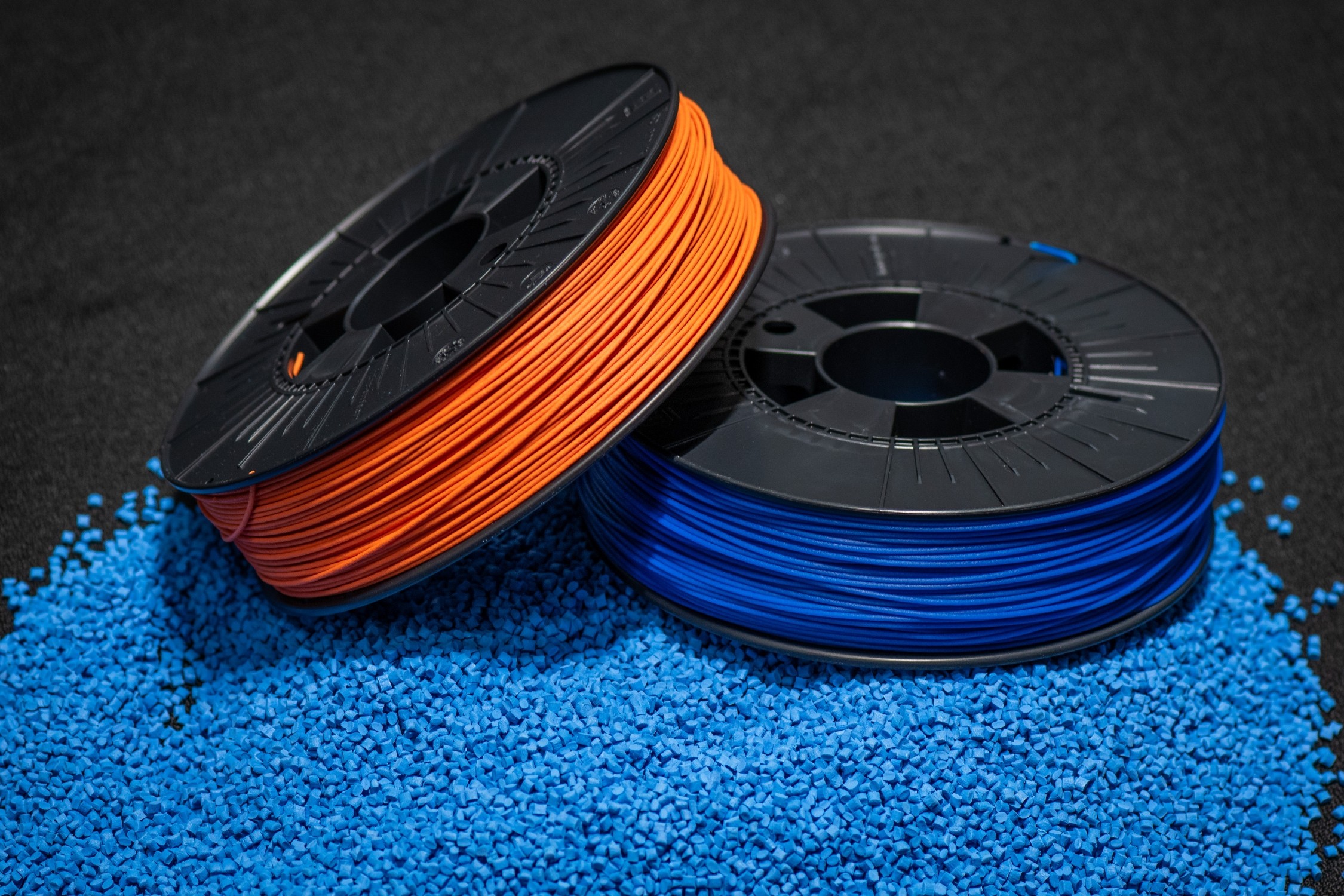

Plastic wire (filament) and granulate from waste 3D printing powder and used parts is used to produce new components using FDM 3D printing.

This waste powder is coming from the production of thousands of components each year. It has previously been disposed of, along with shredded used parts.

The filament is rolled onto spools like wire, which can then be used to print new items, such as auxiliary production devices and tools.

In addition to recycled filament for the Fused Filament Fabrication (FFF) process, the Campus also provides recycled granulate for use in Fused Granulate Fabrication (FGF) technology, thus enabling manufacturing of large tools.

A wide variety of components are now being printed with recycled filament. For instance, at BMW Group Plant Munich, a specific component used in the marriage of chassis and body is now being 3D-printed. This component temporarily secures the steering rod in a defined position, allowing it to be guided through the opening in the body without risk of collision. The reusable component is installed in the vehicle shortly before the marriage and then removed again afterwards.

At the BMW Motorrad plant in Berlin, 3D-printed support pedestals are used in applying decor to the motorcycles’ trim panel. The pedestals, which are customised to fit the trim panel components precisely, also feature locking mechanisms. This ensures the components are held securely in place, preventing them from slipping while the decor is applied.

Solutions to optimise operations are often developed in response to acute workplace needs.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.