If technology now underpins operational resilience, competitive advantage, and regulatory compliance, then staying ahead of the latest advancements or trends becomes even more critical, especially in today’s manufacturing environments.

With no specific order or priority, these technology trends marked the year 2025.

1. The growing rise of AI-powered assistants

If AI is a trend in itself, it is also reshaping several areas of the manufacturing value chain. “Assistant-like” systems, often referred to as AI agents, are increasingly embedded across AM workflows. Not all solutions on the market are fully autonomous agents, but we can expect a growing integration of AI-driven modules that support or accelerate specific steps.

Software companies should be the fastest to adapt. In fact, some of them are already adapting (e.g., Synera, Authentise, etc.), and we can expect a wave of new players whose core business will be delivering AI “assistant-like” systems tailored to engineering and manufacturing.

Read more: Software | How do AM software providers adapt with AI agents?

2. Product design is seeing the strongest impact from AI and machine learning

Among all segments of the AM workflow, product design and simulation are seeing the strongest immediate impact from AI and machine learning. These stages are highly iterative, computation-heavy, and already software-centric, making them the natural entry point for assistant-like tools.

At Formnext 2025, for instance, Siemens was one of the software giants demonstrating how Generative AI is transforming industrial additive manufacturing. As the company explains, this technology acts as an orchestrator, intelligently linking requirements management, design, and simulation.

While the scale of this transformation is still difficult to quantify, engineers should remain aware of potential AI biases that can influence design decisions, sometimes in ways that are detrimental. Moreover, the regulatory and security implications of AI-driven engineering workflows have yet to be fully addressed.

One newcomer we would keep on our radar is opdo, an AI co-pilot for design and simulation, founded by Stephan Kuehr. After coming out of stealth this year, the company aims to help engineers generate advanced, manufacturable optical systems from a simple prompt, in minutes.

Additionally, although design and simulation are leading today, it’s worth mentioning that AI is also entering production planning, QA/inspection, process control, and documentation.

3. Vibe coding: tip or trick?

Vibe coding is a software development approach where a developer uses natural language prompts to direct an AI to generate, refine, and debug code, moving the focus from line-by-line writing to high-level guidance and iteration.

If this approach is drawing attention, its risks are yet to be fully understood. Engineers are using this approach to iterate fast, but turning ideas into something reliable and scalable takes more discipline, mistakes, engineering, and teamwork. That’s something we would need to further explore next year.

4. Binder Jetting: uncertain future?

Binder Jetting found itself at the center of many conversations in 2025, particularly as major players in Europe and the USA faced disruptions in their business operations. Desktop Metal filed for bankruptcy before being acquired by Arc Impact; Voxeljet was delisted, was not sold, and has remained in restructuring for some time; and Digital Metal has all but disappeared from the spotlight since its acquisition by Markforged. ExOne appears to be the fortunate exception, having been rescued by Anzu Partners following Desktop Metal’s collapse. This hubbub doesn’t even include established companies such as HP or Colibrium Additive (formerly GE Additive), both of which are still establishing a foothold in metal BJT.

All of this naturally raises questions about the viability and future of metal binder jetting. From a business standpoint, the technology has long been promoted as a lower-cost alternative to laser Powder Bed Fusion (PBF), still the leading metal AM process across a wide range of applications. From a technological standpoint, metal BJT should indeed be highly promising—fast, scalable, and suitable for mass production. Yet it has not fully lived up to expectations, largely due to challenges in the sintering stage, the heat-treatment process used to densify parts.

Today, the most successful practitioners of BJT tend to be companies with deep sintering expertise from powder metallurgy or metal injection molding. For that reason, the story of metal binder jetting is likely not over. With the right expertise and renewed investment in fixing its limitations, we may still see companies willing to devote the time, capital, and engineering required to make the binder jetting business model work. Perhaps next year will offer clearer signs of that commitment.

5. The development of new high-performance materials

Unsurprisingly, this year, we have observed a clear rise in the development of high-performance metallic materials for additive manufacturing, driven by the increasing need for more performant applications in sectors such as aerospace, medical, energy, and defense.

In particular, there is a strong focus on high-entropy alloys (HEMs), refractory metals, and materials like tantalum and niobium, which offer exceptional strength, temperature resistance, or biocompatibility.

Advances in alloy design, powder processing, and recycling practices are helping to make these materials more viable despite the challenging economics of the industry. The strategic value of these high-performance metals in critical applications continues to encourage investment, making this trend one of the most significant in the AM materials landscape this year.

6. Sustainability in AM continues to be more focused on material-based strategies

In 2024, 3D ADEPT’s sustainability coverage centered largely on recycling and reuse, but with more emphasis on foundational research and proof-of-concept initiatives.

By contrast, in 2025, our coverage has shed light on real-world deployments and partnerships. Notable examples include Continuum Powders recycling nearly one ton of nickel scrap per week from a Siemens Energy facility. EOS’s announcement that its AlSi10Mg aluminium powder is now made from 100% recycled feedstock, achieving CO₂e reductions of 77–83%, also reflects a step change.

The strongest material-sustainability trend in 2025 is clearly industrial circularity in metal powders. Rather than just reusing leftover powder, companies are scaling up the recycling of high-value scrap (like nickel) into qualified AM feedstock, signaling that circular manufacturing is becoming a commercially viable and strategically important part of the AM materials ecosystem.

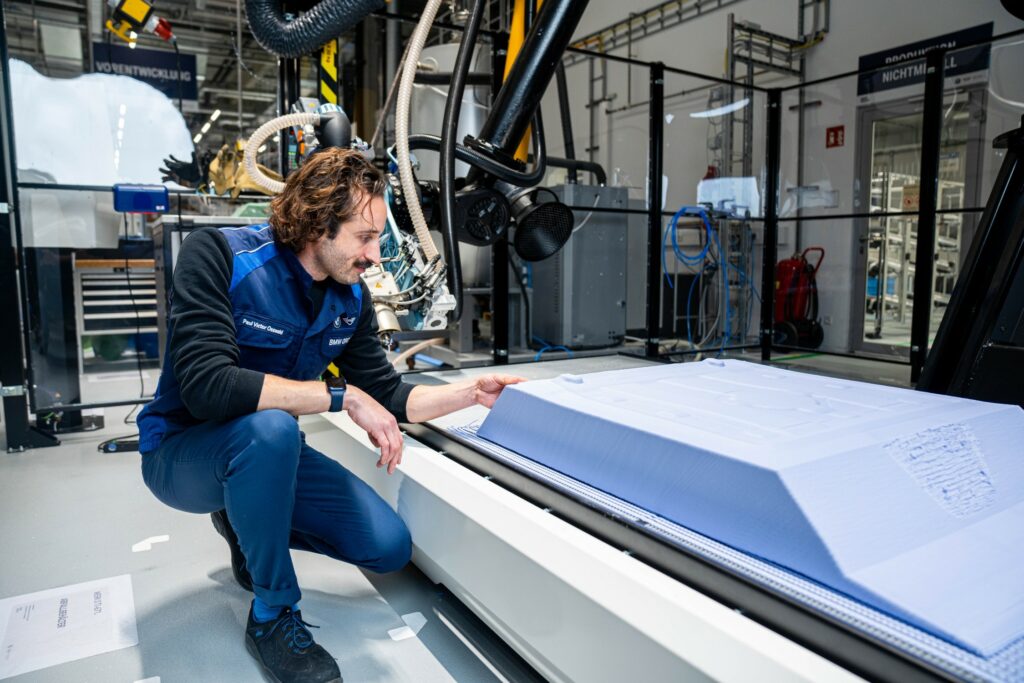

7. Large-format additive manufacturing

At Formnext 2025, large-format additive manufacturing (LFAM) stood out as a defining trend, especially in metal applications via Wire-Arc Additive Manufacturing (WAAM), and LPBF. Gefertec, for instance, showcased its massive arc80X system capable of building components up to 8 m³, including a 700 kg turbine impeller and structural parts for aerospace, rail, and tooling applications. Meanwhile, LFAM isn’t limited to metal.

Other applications showcased highlight the capabilities of large-format extrusion-based systems, underlining how big-part applications are being driven not just by arc-based but also by polymer extrusion technologies.

What did we miss? What’s one trend that you believe has marked the AM market in 2025?

Featured image: 3D ADEPT MAG – Technology trends that marked the additive manufacturing market in 2025

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.