Two material companies, 3D4Makers and Zymergen have worked together on the development of a new 3D printing material. Named Polyimide, the new high-strength polymer is flame retardant and designed for high temperature 3D printers.

Polyimide materials are known for being unstable, difficult to 3D print and for delivering parts that experienced a lot of warping and cracking. The two partners have addressed this issue in this development.

3D4Makers' experience in the field reveals that its high tolerance, high-performance filaments such as PEI, PEEK, PEKK, PPSU and PAHT are currently being used by racing teams, universities, national laboratories, and automotive companies for a variety of applications. The company is especially acknowledged for the fabrication of filaments with lower moisture and better layer adhesion using a unique proprietary manufacturing technology.

Zymergen’s expertise has been pivotal in this development. The company leverages machine learning, genomics, and automation to look for biomolecules that perform better than petroleum-based chemicals. Its goal? Creating bioinspired materials that are more efficient and designed to displace petroleum-based materials.

3D4Makers’ filament is special because it utilizes Zymergen’s Z2 polyimide, which demonstrates low warp and easy to 3D print while having significant Z strength. The new 3D printing material is said to deliver insulating properties and excellent thermal stability, one learns.

According to a press release, this material has demonstrated an (ASTM 1708) tensile strength of MPa 96 and a tensile modulus of 2.41 GPa. The glass transition temperature is 193 C. This polyimide prints at between 390°C-410°C.

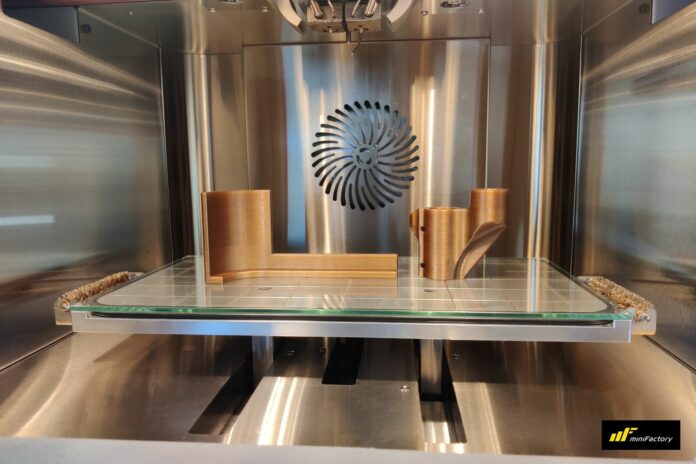

3D4Makers Filament manufactured with Zymergen Z2 polyimide has comparable performance to PEEK but is far easier to 3D print consistently. This material can also lead to higher reliability processes for manufacturing parts. Additionally, parts also do not need to be annealed after printing to perform well. Inherent to polyimide, this material will be applicable for use in harsh environments, and there already has been significant interest from defense, space, energy and racing companies, the same press release reads.

Zymergen and 3D4Makers have announced that they have signed an R&D Supply Agreement to make this material available for sampling to select customers today. The material has been extensively tested by leading high-temperature 3D printing manufacturers miniFactory, OrionAM, Aon3D, and others.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com