Additive Manufacturing company 3D Systems announces a range of new solutions that would enable fast SLA 3D printing. The new solutions include a new series of 3D printers – the SLA 750 stereolithography additive manufacturing (AM) solution -, new materials and a dedicated curing oven to achieve the desired 3D printed part.

The SLA 750 solutions

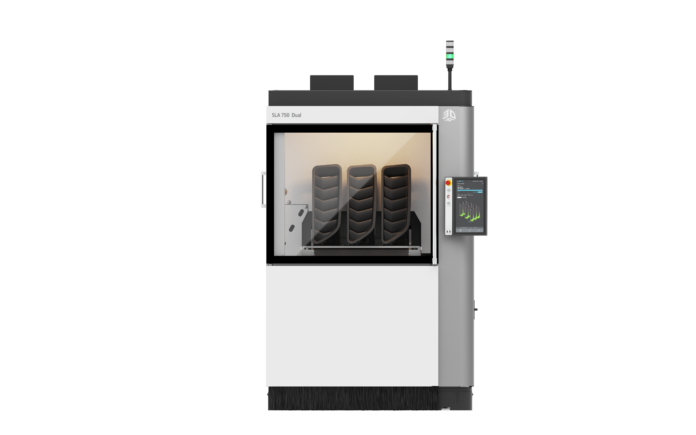

The new portfolio of 3D printers is designed to meet large format or high volume production requirements. They include the SLA 750 and SLA 750 Dual. The manufacturer said the new solutions deliver an ideal combination of print size, speed, accuracy, and resolution for final parts.

The main difference between the two solutions is that the SLA 750 is a single-laser configuration that delivers up to 30% faster print speeds. It is field-upgradable to the SLA 750 Dual. The latter is described as the first synchronous, dual-laser system, which can achieve up to 2X faster print speeds and up to 3X faster throughput than previous generation SLA printers.

Both printers feature a 15% larger build envelope and smaller hardware footprint than previous models, allowing manufacturers to optimize and scale production. The system features a self-calibrating dual-rail recoater to improve print process reliability and final part mechanical properties, 3D Systems explains.

They also utilize a proprietary scanning algorithm named Hyper-Scan™ vector technology. It aims to meet the requirements of production additive manufacturing applications. Hyper-Scan optimizes key speed and productivity elements such as laser focus and power, as well as vector motor kinematics to deliver significantly improved printer speed and throughput. The printers include downstream automation readiness and are robot compatible for 24/7 lights-out operation (e.g., fully automatic printer turnover, job-offloading, washing, on-boarding), a press release explains.

At the software level, both 3D printers also work with 3D Sprint®, the well-known all-in-one software that helps with preparation, optimization, and printing of 3D CAD data.

“We produce hundreds of SLA parts every week, so time-to-finished-part for us is everything,” saidMatt Harman, technical director, BTW Alpine F1 Team. “The SLA 750 increases our productivity and efficiency, allowing us to deliver superior quality production parts faster than ever. The entire system has been engineered for ease of operation, including automation. This is a huge step forward for our additive manufacturing capabilities and we are eager to extend our fleet with two more SLA 750s in 2022.”

The Acura materials

In general, 3D Systems’ SLA resins utilize patented chemistry to deliver long-term mechanical performance and stability for large-scale plastic parts.

The Accura AMX Durable Natural is joining the materials’ portfolio of the company today. This resin is designed to withstand repeated high mechanical loads and shocks with a unique combination of mechanical properties including impact resistance, tear strength, and elongation at break. Accura AMX Durable Natural is tested per ASTM D4329 and ASTM G194 for indoor mechanical performance for up to eight years, and outdoor weathering stability for up to one and a half years. It exhibits similar stress/strain toughness performance to standard thermoplastics, and its isotropic mechanical properties ensure superior part strength in any build orientation.

These properties make Accura AMX Durable Natural an ideal material to deliver large, complex, mandrel tooling cores that can be easily removed from convoluted tubing as a single piece. These are invaluable as manufacturing aids for large cooling ducts, pipes, and manifolds used in automotive, aerospace, energy, and consumer goods applications.

The dedicated curing oven

An integral aspect of any polymer additive manufacturing workflow is drying and curing. To meet the requirements of 3D Systems’ high yield SLA 750 production workflow, the company is introducing the PostCure 1050. This industrial-scale, post-processing system offers high-volume, high-speed drying and curing for batch jobs and large parts up to 1050mm x 750mm x 600mm. The PostCure 1050 delivers cure times and throughput that are 5X faster than comparable solutions due in part to consistent 360° light uniformity which allows more parts to be cured in less time without manual intervention (e.g., part flipping). Long-life LED light sources, automatic detection and alert of light failures, and a one-step light output calibration routine help ensure more predictable, consistent part and job outcomes. Additionally, optimized light wavelengths, a separately configurable UV intensity, and actively cooled LEDs each with its own adjustable heating enable optimal part cooling without thermally-induced warp.

PostCure 1050 is compatible with all 3D Systems resin printers and suitable for all current and future material innovations. General availability of the system is planned for the third quarter of 2022.

“I see the launch of this new platform – which includes a synchronous dual-laser option, Accura materials, and the specialized curing oven – as an example of how we are executing on a global AM strategy that focuses on our strengths,” said Dr. David Leigh, executive vice president & chief technology officer for additive manufacturing, 3D Systems. “I believe we are entering an era where there will be a path of rapid evolution to our innovations. In this light, our multi-purpose SLA platform will become a system that can help scale production applications through built-in functional and throughput enhancements.”

In the meantime, industries that are looking to maximize true production agility, can already benefit from a seamless integration into existing workflow with Oqton Manufacturing OS.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com