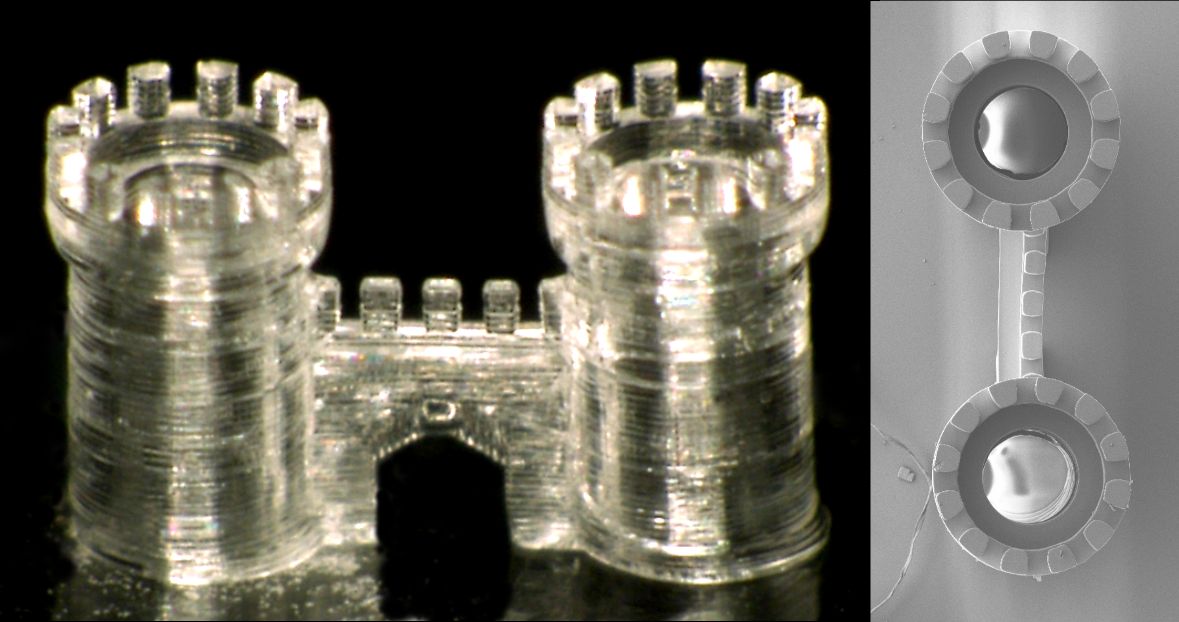

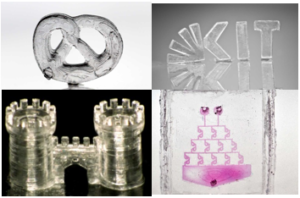

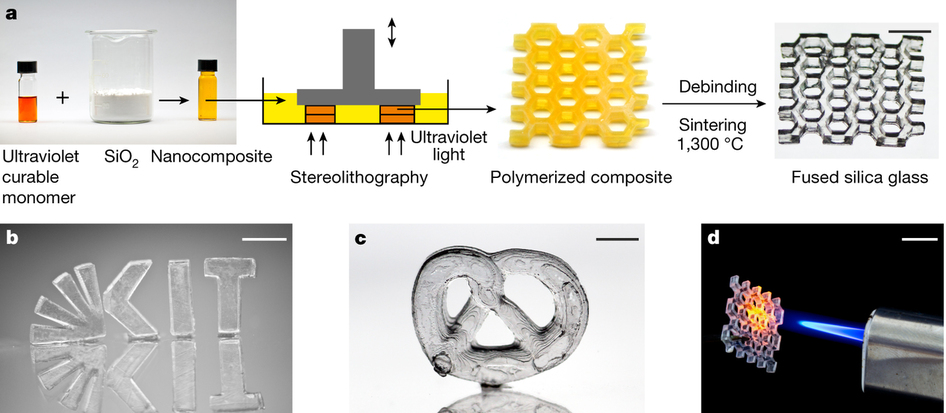

Thanks to the Karlsruhe Institute of Technology (KIT) scientists can now use glass to realize extremely small and complex structures via 3D printing.

According to Bastian E. Rapp, KIT’s mechanical engineer who led the research, transparency, thermal stability and resistance to acids are glass properties that bring up new perspectives in 3D printing.

The use of glass in 3D printing can be exploited in many fields: optics, data transmission or even biotechnology.

Glass is actually one of the oldest materials of mankind. However, the various printing techniques available so far have only been used on polymers or metals, and never on the glass. It turns out that whenever the glass has been transformed into structures, the surface was rough, the material, porous and contained voids. One example of that is the glass which is processed by melting and applied by means of a nozzle.

This is why for Rapp, they present “an innovation in materials processing, in which the material of the piece manufactured is high-purity quartz glass with the respective chemical and physical properties.”

Precision here is the most tangible because KIT scientists realized glass structures that show resolutions in the range of a few micrometers taking into account that a micrometer equals one thousandth of a millimeter.

We can’t wait to appreciate the first productions based on 3D printed glass.