It is possible with 3D Printed PVA to cast high detailed objects from Metal Fluid.

“Metal Fluid is a mix of metal grit in a resin binder that looks, feels, and weighs almost exactly the same as brass, bronze, and other metals.”

“Metal Fluid is a mix of metal grit in a resin binder that looks, feels, and weighs almost exactly the same as brass, bronze, and other metals.”

The truth is, it is not always possible to cast an object in a traditional two-part folding mold. Some details and complex shapes have proven a barrier to that. That’s why, disposable 3D printed PVA molds are a good solution in such situations.

How to Create 3D Printed PVA Molds : the case of Egyptian-themed figures

Designer Eliza Wrobel made disposable 3D printed PVA molds of Egyptian-themed figures originally designed by Zorum. The PVA molds would allow her to recreate the high level of details from the original 3D model.

First of all, she designed simple mold forms with inlets around the models.

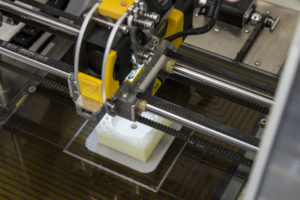

She secondly used a PVA preset to prepare her molds and to adjust it for 1.75 mm Plastic Extruder mounted on ZMorph 2.0 SX multitoool 3D printer. Notice is to be made that after several hours of 3D printing the molds, no post-processing was needed at this stage.

3D printed Molds are important because their forms do not change once the material starts giving back heat. After a 24 hour-immersion in water, PVA molds dissolved completely. Once the model is cleaned, casted figures required sanding to eliminate 3D printing layers and a resin residue that settles over the metal.

Anyway, this method is easier to use and less time-consuming than traditional mold making and metal casting methods.

//pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});