Recently, 3D-printed homes have come into the spotlight due to their potential sustainability, durability, and affordability. In reality, building these homes has been very limited. However, this is about to change. The partnership between Sunconomy, a building company from Austin that specializes in tiny homes, and Forge, a residential development company from San Francisco, aims to promote 3D-printing houses and to make them more widely available.

These two companies plan to license and lease the “We Print Houses 3D-printing Home System” by Sunconomy to contractors and builders throughout the country. This system incorporates a mobile platform, as well as all the necessary mechanical systems to construct the designs.

Once this technology becomes widely available, licensees will need to take part in a special certification and training program that lasts for two weeks. There is a 3D printed concrete home known as the “Genesis model” scheduled to commence in February. It will be the first house in the States to be created, managed, constructed, evaluated, and marketed with this 3D technology. The Genesis model is to be built on a sloped lot with dimensions 100×120 feet, called Lago Vista in Texas. The lot is chosen with a purpose to demonstrate the flexibility of the 3D designs and the construction works will start in February.

Benefits of 3D-Printed Homes

3D-printing homes will comply with the International Building Code including cladding fire standards that have recently been established. They offer a plethora of benefits to their users, including energy efficiency and low maintenance. They’re also resistant to floods, hail, fire, strong winds (including tornadoes and hurricanes), as well as earthquakes higher than eight points.

Let’s look at some of the benefits of 3D-printed homes in detail.

Faster process

Traditional construction methods use materials like concrete that take a long time to settle and dry. At the same time, these materials are more susceptible to damages caused by transport. With 3D printing, you don’t need to worry about this. While a standard house can take between six and seven months to build, the whole process of constructing a 3D house takes only a few weeks!

Durability and strength

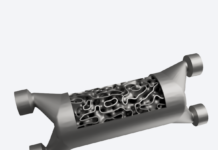

Despite popular belief, 3D-printed homes are not inferior to their traditional counterparts when it comes to structural strength. On the contrary, 3D printing technology guarantees a fewer number of stress points in the structure which, in turn, means a stronger building.

Reduced costs

Using 3D printing can significantly reduce construction costs because it uses a minimal amount of materials and labor while reducing the risk of defects due to human error. It’s expected the cost savings will be up to 60%.

Flexibility

When it comes to utility and design, 3D-printed homes offer countless possibilities. For instance, you can adopt curvilinear structures that are known to be stronger and more stable. Designers can experiment with different options and offer homeowners a house tailored to their style and needs.

Reduced waste

The 3D printing technology reduces waste by using more sustainable construction materials. When it comes to the materials used, there are constant developments and breakthroughs. For instance, some 3D homes can be built with bio plastics made from vegetable oil!

We’re excited to see 3D-printed homes develop and where that takes us in the future. While the technology is still in its infancy, there is great potential for the technology to create healthier, more comfortable lives without negatively impacting the environment. The technology provides an opportunity to minimize harm to the environment during construction by efficiency in the building process thereby producing less waste. The flexibility in design also allows architects and building designers to use their creativity to make the most of a particular sites environmental characteristics. The reduced costs may also help free up a clients budget to invest more readily into the specifics that make a great home.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media.For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com