ZW3D, a supplier of CAD/CAM solutions for the manufacturing industry, published a review of its CAM features, made in collaboration with Daniel Dobrzynski. The review lays emphasis on the CAM tools and highlights enhancements in ZW3D software.

For the information, Daniel Dobrzynski, is a specialist of CATIA, SolidEdge and AutoCAD. He provides a different insight into ZW3D, an affordable all-in-one solution.

4 topics are highlighted in the review to enable users to get a better understanding of ZW3D CAM.

Intuitive and User-friendly UI

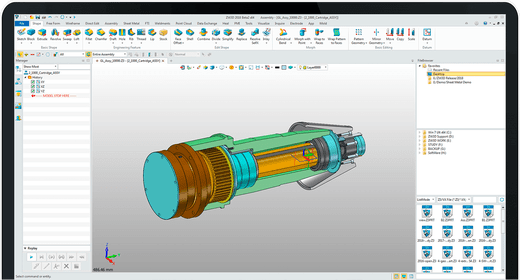

The layout of ZW3D is very intuitive. Delivered with a user-friendly interface and commands, it can be used both in CAD and CAM environments, and enables users to get flexible interaction between design and manufacturing objects.

Further Simplication – 2-Axis Milling Operations only in 4 Steps

According to Daniel, the user who has machining methods knowledge can quickly create operations in ZW3D without requiring any training. Furthermore, the application integrates dialog boxes and natural workflow to help the user if requested.

Plenty of Options to Cover All the Necessities in 2-5 Axis

ZW3D CAM would cover most typical production scenarios in 2-5 Axis. “ZW3D includes all standard and expert tools for machining high-quality complex parts with 5-axis CNC machines.”

2 to 5 Axis Improvements in ZW3D 2018

In addition to the recently added options into ZW3D CAM, it should be noticed that the 5-axis Point Control guarantees tool axis that will go through the control point and which is useful for undercut machining with shorter tool lengths. Moreover, new Multiple Layer 5 axis cutting can extend 5 axis roughing capability.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!