If the deal is sealed (or when the deal will be sealed), Link3D will continue to be managed by its existing management team. Materialise expects to exercise the option before the end of the year.

If you are familiar with industry news, then you certainly know that the AM industry is undergoing a wave of mergers and acquisitions in all fields of activity: materials, 3D printer, post-processing, 3D printing service providers and even software.

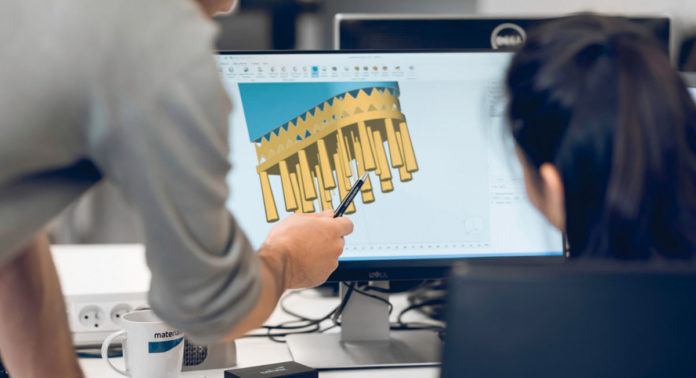

Speaking of this latest segment, we just learned that Materialise has acquired an option to buy Link3D Inc. The Belgian 3D printing giant is known for a wide range of product and service portfolio in the AM industry but if this actually happens, this acquisition is likely to benefit its software segment.

For those who do not know, Link3D is acknowledged for its suite of modular solutions that help organizations plan, manage, and optimize their AM supply chain. The company delivers its solutions in major manufacturing industries, including aerospace, automotive, consumer, medical and energy. With an additive workflow and manufacturing execution systems (MES) company onboard, Materialise would see its software activities reach another level of production and performance.

Enhanced control and cloud manufacturing at its fingertips

For the software expert, this would mean more control of the manufacturing floor as companies will scale up their additive manufacturing (AM) capability into volume production.

Furthermore, a fast adoption of AM might come down to the ability to automate as many processes as possible onto one unique platform and sometimes, the best way to do that is to bet on cloud manufacturing. Indeed, Covid-19 has expedited the need for digitization. By having Link3D by its sides, Materialise sees here an opportunity to offer companies cloud-based access to its unified software platform.

Not to mention that every acquisition comes with an extended portfolio of customers for both the purchaser and the subsidiary. For Materialise, this means a larger customer base across North America, Europe and Asia Pacific and for Link3D, a seamless connection to Materialise’s Magics 3D print suite.

“By joining forces with Link3D, we expect to be even better positioned to provide our customers with a solution to plan, manage and optimize their AM operations”, said Fried Vancraen, CEO of Materialise. “This agreement exploits the synergy between the two companies and will help us to remove some of the complexity associated with scaling 3D printing as part of a connected, industrial manufacturing process.”

A SaaS-focused strategy

Materialise and Link3D each offer MES-solutions that help organizations cope with diverse, complex and distributed manufacturing environments.

With an ambitious roadmap to evolve its entire software suite to a SaaS model, offering its customers cloud-based access to a complete platform of software tools to manage and control the 3D printing process more efficiently, Materialise wants to enable mission-critical applications for industries.

As a matter of fact, the company has recently announced several cloud-based software solutions, including Magics Storefont, a full e-commerce and CRM solution in one platform; and the Process Tuner, an intuitive online platform that helps speed up the process tuning that is required for mass-manufacturing 3D printed parts.

“At Link3D, it has always been our mission to help companies unlock the full potential of AM into their existing supply chains”, Link3D CEO Shane Fox said. “By teaming up with Materialise, a global pioneer of the 3D printing industry, we expect to be able to offer our combined user base access to a robust and comprehensive manufacturing suite of solutions, enabling them to take Additive Manufacturing to the next level“, Link3D Co-Founder and CTO Vishal Singh said.

As per the words of Stefaan Motte, VP and General Manager of Materialise, both companies share a “commitment to support companies as they build cost-efficient and productive 3D printing factories”.

From an industry perspective, customers can get ready to benefit from seamless access to Materialise’s Magics 3D print suite for AM part preparation, automation and production optimization, but also broad 3D printer connectivity and automated workflows.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com