Have you ever tasted Waygu Beef? To be honest, I have never tasted it but from what I have heard, it is described as synonymous with luxury as caviar or black truffles. The term which means “Japanese beef”, is associated with a lot of prestige and has found its way into the realm of cultured meat.

With the high demand for artificial steak-like meat, researchers from Osaka University have managed to create 3D-printed Wagyu beef. Described as a first of its kind in the world, the 3D printed Waygu beef resembles the one made from the world-renowned Wagyu beef cattle.

Beyond the issues that surround conventional animal husbandry, there is also a “protein crisis”, there is also a subsequent increase in food demand that results from the world’s growing population (which is expected to exceed 9.7 billion by 2050).

As plant-based protein and cultured meat are considered as alternative protein sources, why not imagine a 3D printed alternative for the most luxurious meat in the world?

The manufacturing process of the 3D printed Waygu Beef

One of the main challenges with cultured steak is to provide a composition and a structure similar to real steak, comprising mostly adipose cells and aligned muscle cells.

Among the many tissue engineering techniques that could be applied, one notes sheet engineering, cell fiber engineering, cell culture on a 3D-printed scaffold, and 3D cell printing for mimicking the structural characteristics of steak.

In this specific case, they first developed an original tissue modeling technology that used 3D bioprinting to develop tendon-like gels that could be assembled to fabricate a steak-like meat structure that was 10 mm long and 5 mm wide. Named tendon-gel-integrated bioprinting (TIP), their technology enabled the fabrication of meat structures with different tissue make-ups, in order to more accurately replicate their real meat equivalents.

“To enable us to use 3D printing technology to stably produce muscle, fat, and blood vessel tissue, it was important to suppress the contraction that occurs during differentiation induction,” said Professor Michiya Matsusaki of Osaka University. “Focusing on the fact that tendons support muscles in the body, we therefore produced ‘artificial tendon tissue’ using type I collagen, the main constituent of tendons. By then attaching each fibrous tissue to the artificial tendon tissue, it has become possible to stably create the fibrous tissues for production.”

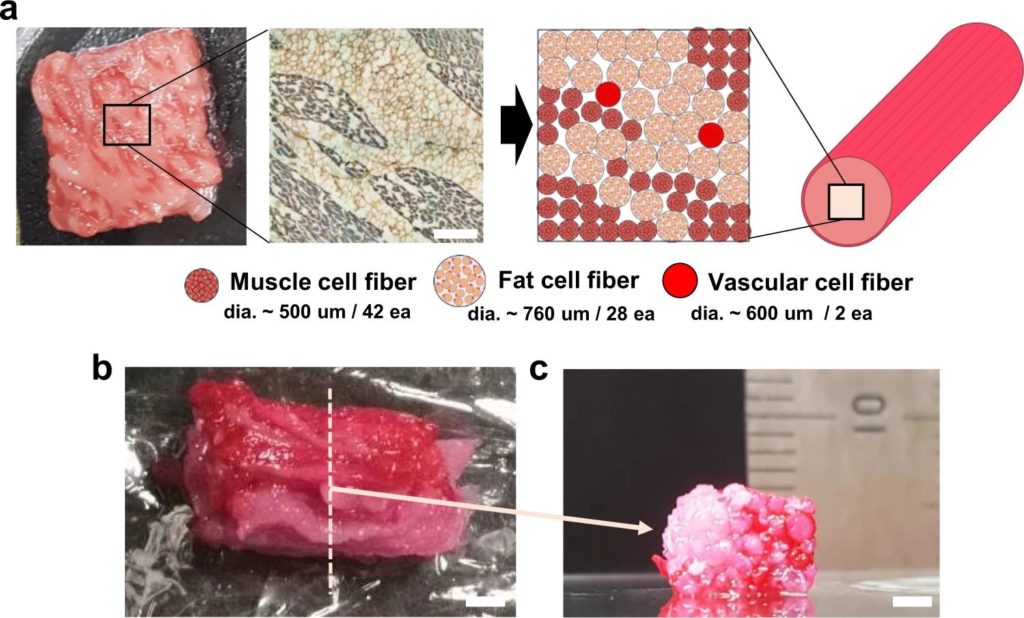

Created based on isolated stem cells from Wagyu cows, those stem cells have been incubated and converted into muscle, fat, and blood vessel cells. The research team utilized a cross-sectional image of a Wagyu cut to utilize a model pattern which revealed the required number of muscles, fat, and blood capillary cell fibers needed, as well as their arrangement. The TIP process helped obtain the cell fibers which were thereafter stacked in line with the model image, before being treated with transglutaminase, a common food cross-linking enzyme, to accelerate the assembly process.

“A total of 72 fibers comprising 42 muscles, 28 adipose tissues, and 2 blood capillaries were constructed by tendon-gel integrated bioprinting and manually assembled to fabricate steak-like meat with a diameter of 5 mm and a length of 10 mm inspired by a meat cut” a report published on nature reads.

Moving forward, improvements of this process will enable to develop complex meat structures that replicate the individual characteristics of different meat types and cuts, but also to control the fat and muscle content of cultured meat.

From a technological standpoint, it will crucial to leverage automated equipment other than 3D printing. This might include cultivation, which could also make it possible to produce cultured meat in any location.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com