Vittori’s roadmap is packed with projects that involve the use of additive manufacturing for hypercars, eVTOL, and electric jet programs. The company that engineers and builds hyper‑performance machines for land and sky, aims to cover design‑for‑additive reviews, rapid prototyping, and pilot short‑run builds of 3D‑printed parts.

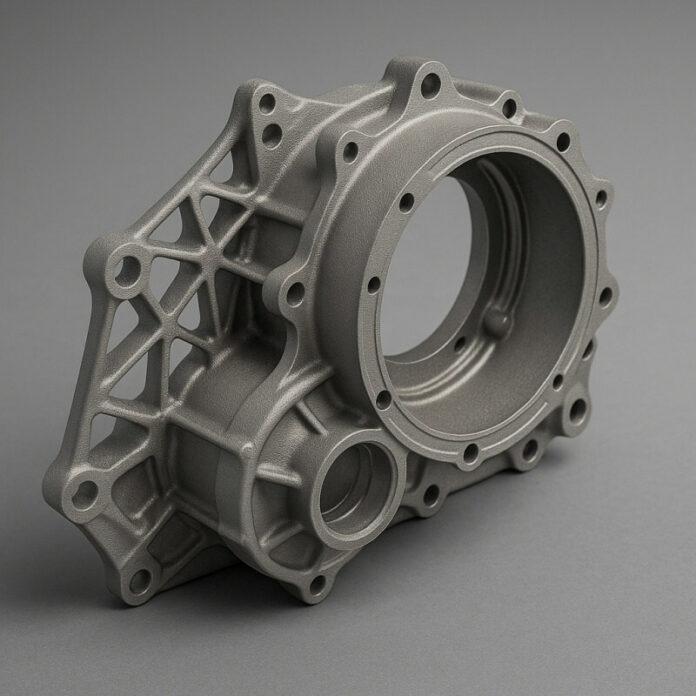

To do so, it has partnered with Totum 3D and ShapeUp Studios, which will support the design, prototyping, and manufacture of titanium 3D-printed components.

Totum 3D provides high-performance material additive design, prototyping, and short-run production for performance-critical applications whereas Shapeup Studios provides Design solution development with shape research, seeking a balance between aerodynamics, lightweight, and tactile finishes.

The partners will first focus on Vittori’s AI-hybrid hypercar, the Vittori Turbio—featuring a V12 targeting about 1,100 horsepower and 3D-printed titanium components. It is scheduled for unveiling on October 4 in collaboration with Pininfarina.

Testing a practical mix of materials

The teams are testing a practical mix of materials—titanium for strength‑to‑weight, stainless and maraging steels for heavy loads, aluminum alloys for light structures, nickel superalloys for hot zones, copper alloy for cooling hardware, and aerospace polymers like PEEK and ULTEM for cabin‑safe components (examples include 316L and 17‑4PH stainless, AlSi10Mg and Scalmalloy aluminum, Inconel 718, and CuCrZr).

For larger sections, they pair printed parts with carbon‑fiber panels and honeycomb cores, and any cabin‑facing materials will be qualified to meet aviation flame, smoke, and toxicity standards.

“As others explore aerospace concepts, we’re putting titanium parts into production now,” said Carlos Cruz, founder of Vittori. “Proving hardware on the road first lowers risk and speeds our move to the air. The same printed structures and thermal systems will migrate into our eVTOL and, later, our electric jet.”

“Vittori’s road‑to‑air plan is a strong fit for metal additive,” said Stefano Turconi, Head of Totum 3D. “Common, lightweight architectures reduce part count and lead time while meeting demanding performance targets.”

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.