A Swedish-based material development firm, VBN Components AB successfully conducted its first in-vitro biocompatibility tests of 3D-printed metal Vibenite® 350 in the competence center AM4life.

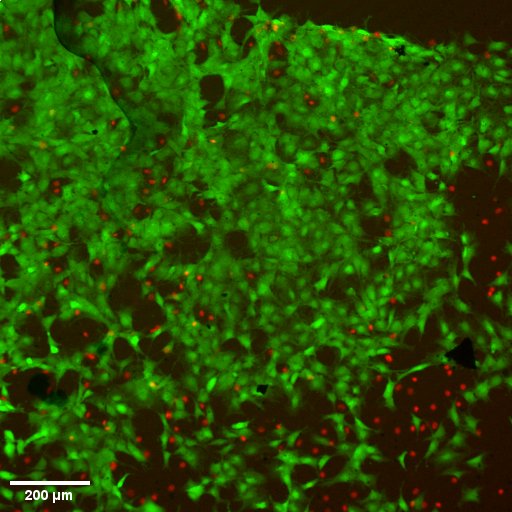

The Vibenite® materials deliver extreme wear and heat resistance. The initial outcomes of the biocompatibility test made with Vibenite® 350 reveal that bone-shaped cells spread across & get multiplied over the material. These observations pave the way for a highly extensive inspection of the material’s biocompatibility features.

Thanks to its properties Vibenite® 350 can be used as an implant material for applications such as human joints where wear resistance is a vital factor. Also, Vibenite® 350 is a cobalt-free material that can replace traditional materials without any wear resistance. Meanwhile, it can be 3D-printed with complex shapes that optimize bone cell growth.

Assistant Professor Gry Hulsart completed the primary tests at Billström’s Translational Bioprinting Group from Uppsala University after being accompanied by AM4Life Director Professor Cecilia Persson, members of the Tribomaterials Group at Uppsala University, PhD Student Vidhiaza Leviandhika and Professor Urban Wiklund.

Further studies of Vibenite® 350 can be done in the AM4Life competence center with modern biological and tribological tests.

Ulrik Beste, CTO of VBN Components AB says, “We are happy with these results and the good cooperation in the AM4life competence centre. When different research fields meet, the greatest results are achieved. But everything relies on good cooperation and the world-class science of this centre.”

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.