Ursa Major, America’s privately funded company that focuses solely on rocket propulsion, received a $12.5 million joint investment contract in partnership with the US Navy to mature its Lynx solid rocket motor (SRM) manufacturing process.

Ursa Major is one of the inaugural recipients of investments from the Office of Strategic Capital (OSC) that will strengthen critical supply chain technologies needed for national security.

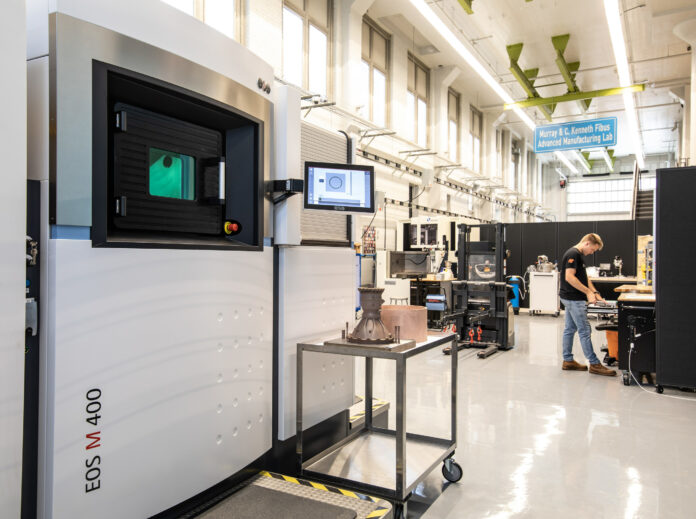

Fundamentally, the investment will serve to leverage advancing manufacturing capability in the areas of propellant manufacturing, additive manufacturing, and composite case winding in support of SRMs for national security missions. As a reminder, Ursa Major delivered its first copper-based 3D-printed rocket engine combustion chamber out of its additive manufacturing lab in Youngstown, Ohio, compressing the production and delivery cycle to one month, compared to a minimum of six months using traditional manufacturing processes.

Therefore, we expect the use of advanced processes to lead to better design flexibility and efficient production.

Dan Jablonsky Said, CEO of Ursa Major, “We are proud to work with OSC on their mandate to expand the defense industrial base by bringing innovations into the DoD ecosystem. Ursa Major is revolutionizing manufacturing approaches used in propulsion development in the United States, building flexibility of production and scalability into manufacturing for our defense customers.”

Ursa Major’s investment will be used to complete an advanced manufacturing pathfinder program for the design, manufacture, and test of a Navy SRM prototype. Ursa Major is currently developing a second source Mk104 Dual Thrust Rocket Motor (DTRM) for the Navy under a separate award.

Author: Nagarjun M

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.