Most thermoplastic materials tend to absorb moisture from the atmosphere. It is also common, that newly opened filaments already contain a significant amount of moisture that affects the printing process. Hissing and popping sounds, are the first tell-tale signs that one is printing with wet filament. This happens because the water absorbed by the plastic is very quickly vaporized by the heated nozzle. As a result of this rapid phase change, inconsistent material extrusion and nozzle blockages are a common occurrence.

This inconsistent material extrusion will have several visible effects on your prints. Stringing and oozing in prints will be more pronounced as the added pressure in the hot end results in less control over the amount of extruded material. The strength of the print will also be negatively affected. As water changes to steam, voids (bubbles) will be trapped inside the filament and ultimately the print, reducing layer adhesion and the overall part strength. Parts printed with correctly dried filament tend to show less of these artifacts, resulting in a better surface finish and superior strength.

To address this issue, Thought3D, a Malta-based technology company has developed a solution to ensure reliable and consistent filament drying during printing.

There are usually several conventional ways to dry wet filament with most manufacturers recommending an oven to heat up the filament and drive the moisture out. However, that strategy has several drawbacks. Conventional filament drying methods tend to be overly time and energy consuming as the filament must be dried for several hours before it can be used for printing. The spools themselves, onto which the filament is wound, need to be from specific materials to be able to withstand the heat in the oven. In some cases, the material might not be consistently dried throughout the filament spool. During longer prints some materials tend to pick up enough moisture to negatively affect their quality, even after being correctly dried before unless stored in special filament storage solutions during printing which help to reduce this issue.

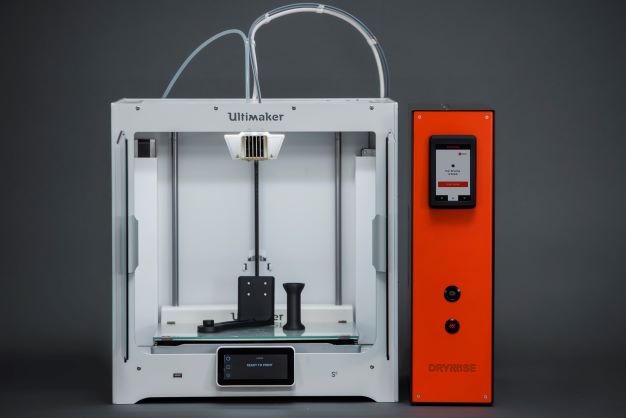

Priced at $1,663 and already available on the US market, the new in-line filament dryer for FFF 3D printers is designed to be used in tandem with a 3D printer to dry hygroscopic filaments in real time during printing, this way, the material remains at the best possible conditions throughout the duration of the 3D printing job.

After a short pre-dry cycle on the first portion of the filament, the user can load this filament and print with ease and peace of mind as the filament will be dried consistently for the whole duration of the print.

Drywise, the patent-pending, active, in-line drying technology can also detect any idle moments to guarantee consistency and safety. The device’s user-friendly interface guides the user all the way and exchangeable and rechargeable desiccant cartridges eliminate down time. The list of materials certified to work with Drywise is always constantly growing.

“We’re really excited to bring this innovation in 3D printing from our labs in Malta to the United States,” said Andrei-Andy Linnas, co-founder, Thought3D. “We believe the 3D printing process should be about creativity and productivity – not worrying about reliability. Drywise eliminates the longer drying cycles and pre-planning routines with a drying solution that is fast, intelligent, user friendly and consistent.”

Drywise was created to fill the gap left by these conventional solutions as 3D printer users want to spend less time preparing and more time completing their 3D printing projects, whether they are for tooling, functional prototyping, industrial modelling, or end-use parts production.

To sum up…

Active in-line drying, as made possible by Drywise, solves drying issues once and for all:

- In-line drying allows for perfect drying over the whole duration of the printing cycle regardless of how long the print is.

- Consistent drying is guaranteed regardless of the initial material conditions.

- Material heat cycling is eliminated as only the right amount of filament needed for printing just in time for printing is dried.

- No spool size or material limitation as the drying happens inline

- Easy operation with pre-calibrated material specific drying profiles making the whole process seamless.

- Specific add-on developed (sold separately), for especially hard to process materials

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com