In general, if you take a short piece of your filament, and bend it back and forth, similar to how you’d bend a metal paper clip; if it breaks after a few bends, it likely needs drying. If it withstands several bends, it’s probably fine.

To make it simple for users, especially those working with engineering materials, most 3D printer manufacturers have developed a filament drying device that could be used with their 3D printers.

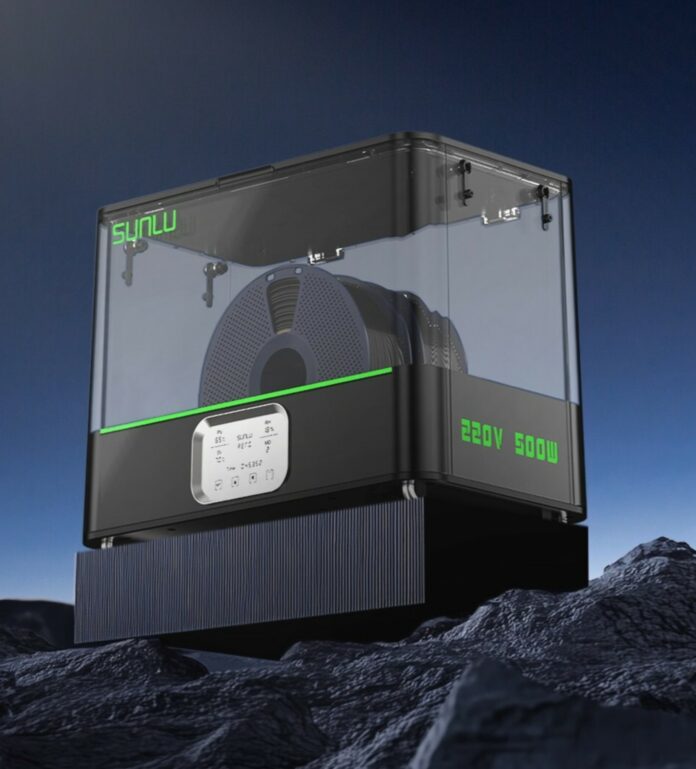

One 3D printer manufacturer who recently unveiled such a solution for its portfolio is SUNLU, a 3D printer manufacturer headquartered in China. Its device, FilaDryer E2, is designed for efficiently drying and annealing engineering filaments.

If you’re a beginner in the 3D printing industry, keep in mind that drying filament at the correct temperature removes any moisture it may have absorbed whereas annealing is a process of raising the temperature to enhance an object’s firmness, tensile strength, and heat resistance.

Key features of the FilaDryer E2 device

SUNLU’s solution can achieve up to 110°C drying temperature. According to the company, it is ideal for handling moisture-sensitive materials like PA and PC by drying at 90°C in just 2–3 hours, significantly improving efficiency.

With a user-friendly one-touch drying function, the E2 automatically provides optimal drying settings for the most common filament types. The FilaDryer E2 features a dual-chamber insulation ensuring efficient, consistent and energy-efficient drying by trapping heat and blocking external moisture.

Furthermore, its annealing feature allows users to achieve superior strength, stability, and durability in their prints, particularly with engineering-grade materials like PA and PC.

The FilaDryer E2 accommodates up to one 3kg/2kg spool or two 1kg spools (maximum spool size: φ250mm×153mm). This makes it the ideal choice for users working with larger spools, providing the convenience of handling bulk materials without frequent spool changes.

Last but not least, the device prioritizes user safety with a dual-layer insulation structure that maintains exterior temperatures below 60°C, even at its maximum drying temperature of 110°C. A high-temperature-resistant fan, a PTC heater, and an automatic power-off system safeguard the device during prolonged use.

Remember, you can post free-of-charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com.