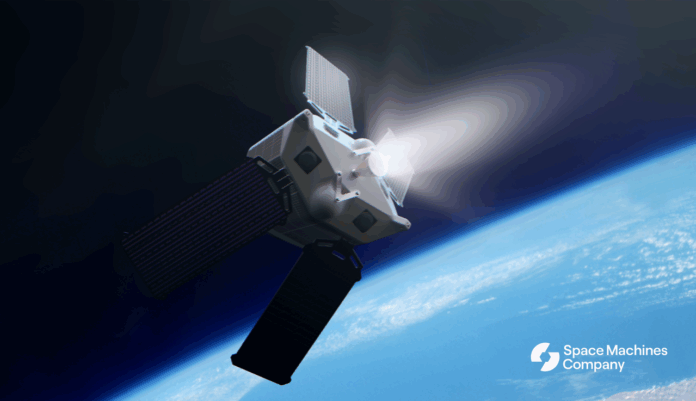

Space Machines Company (SMC), a leading Australian space technology company, today announced the successful completion of its proprietary Scintilla propulsion engine. The engine has achieved extended burn durations of 65 seconds with over 1,200 seconds of total testing time and 40 restarts and counting, representing a critical advancement in the company’s Rapid Response Vehicle – Optimus Viper, designed for rapid orbital manoeuvring and space domain awareness missions.

The Scintilla engine, developed entirely in-house by SMC’s propulsion team, delivers 50 Newtons of thrust while maintaining 92% efficiency, exceeding the company’s initial 90% efficiency target with a clear pathway to near-100% efficiency in future iterations.

“We’ve achieved faster progress than even our most optimistic schedules predicted,” said Rajat Kulshrestha, Co-Founder and CEO of SMC. “The engine has reached steady-state conditions and demonstrated the ability to run for extended periods – a critical requirement for our satellite operations. We can now run this engine for minutes, limited only by total propellant supply from our tanks.”

Unlike traditional satellite manufacturers who typically outsource propulsion systems, Space Machines Company has invested in complete vertical integration for this mission-critical technology. The decision reflects the central role propulsion plays in the company’s satellite capabilities, with the Optimus Viper platform designed around extensive orbital manoeuvring requirements.

“Propulsion is absolutely core to what Space Machines needs to do,” explained Ian Partis, Vice President, Engineering and Mission Operations at SMC. “The better the propulsion system and the more delta-v available, the greater range of orbits we can access and the faster we can get there. This is so fundamental to our mission that the satellite is essentially a propulsion system with a payload on top.”

From design, development testing, and critical design review phases.

The propulsion system’s design allows for significant performance scaling, with the ability to increase thrust from the current 50 Newtons to 100-500 Newtons through relatively minor modifications.

The successful completion of Scintilla demonstrates the effectiveness of SMC’s “build-to-learn, learn-to-build” development philosophy. The team discovered failure modes through rapid iteration, maintained multiple backup systems, and ensured continuous learning capabilities through co-located testing and manufacturing facilities.

“Having everything vertically integrated means we can respond immediately to design changes without external contractor delays,” noted Rajat Kulshrestha. “When the team identified an issue during testing, they were able to diagnose it within 10 minutes and implement solutions immediately. This kind of responsiveness is impossible when working with external suppliers.”

Final accomplishments include:

- Extended burn capability: 65-second continuous operation with demonstrated ability for longer durations

- High efficiency: 92% performance with an engineering pathway to 99%+ efficiency Scalable design: Architecture capable of 10 x thrust output with minimal modifications Restart capability: Multiple ignition cycles for complex orbital manoeuvres

- Robust operational envelope: Tested across varying conditions to ensure reliable performance

Looking for a job in the AM industry or hiring new talent? You can post job opportunities on 3D ADEPT Media for free or explore openings via our job board. Stay connected by following us on Facebook, Twitter, LinkedIn & Instagram, and subscribe to our weekly newsletter for the latest updates. Have a story to share or want to be featured in our next digital magazine issue? Send it to editor@3dadept.com !