Understanding generative design and topology optimization in additive manufacturing

Changing its manufacturing process for additive manufacturing does not only mean to change its manufacturing system. A meaningful change starts from the root: software. Indeed, traditional CAD restricts designers to known geometries and facilitates the re-use of previously designed parts, resulting in robust but nowhere near optimal designs.

With the increasing adoption of AM and its ability to produce intricate geometries, generative design is now gaining momentum in the industry. The only thing is that engineers that are supposed to design for AM still have CAD systems that do not integrate the necessary generative design functions.

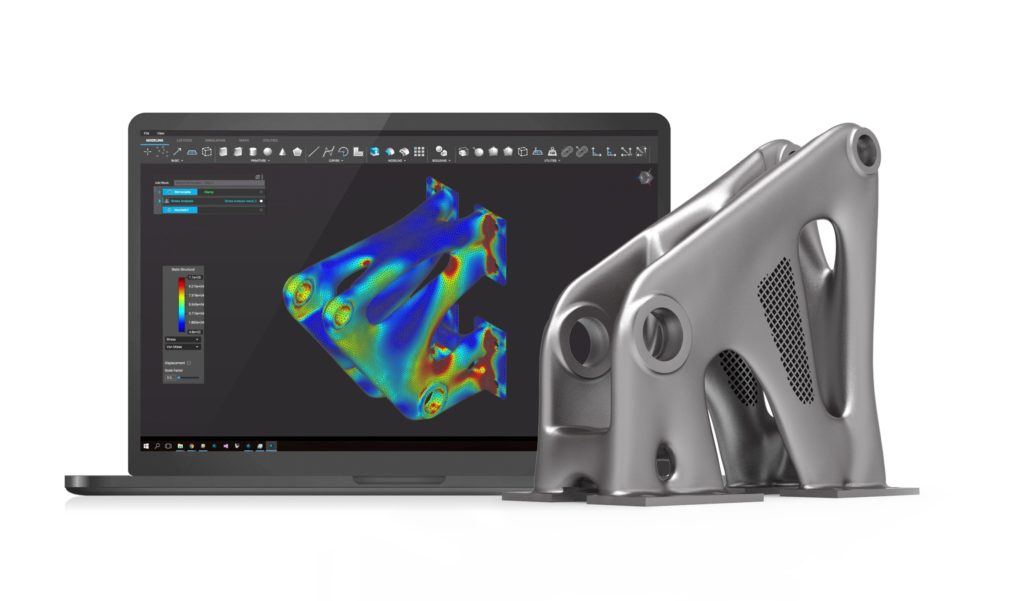

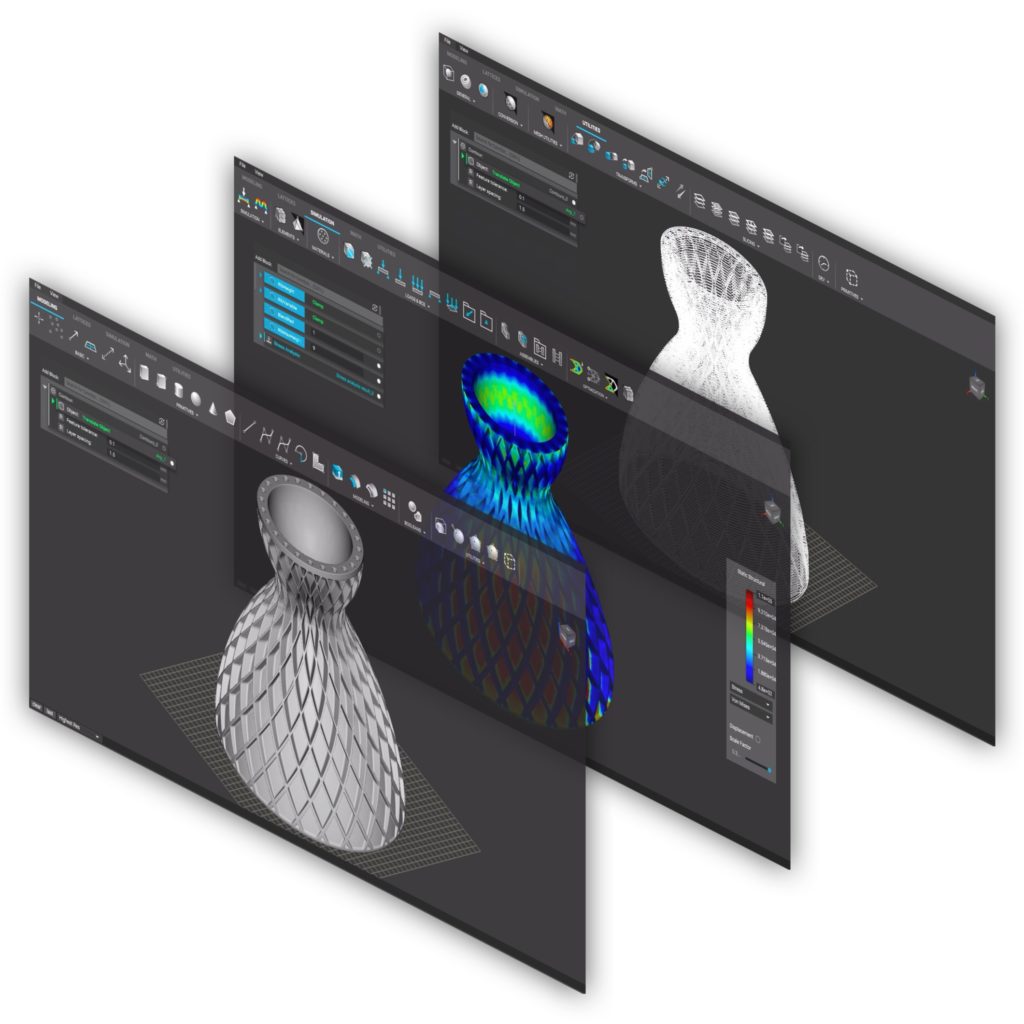

Generative design and topology optimization aim to close this gap with evolutionary algorithms and optimization on various parts of the software. Anyway, that’s the aim of nTopology and one reason why we invited Bradley Rothenberg, cofounder and CEO of the company in this Opinion of the Week series, is to discover the complexity of this concept. You probably got it, nTopology is a software company that creates engineering solutions using advanced computational methods for designing high performance products.

Before delving into this Q&A series, let’s clarify something: there is not yet a standard definition of generative design. As per the words of Rothenberg, “to most it means using a specific algorithm for topology optimization to generate a design” but he would prefer a much broader approach to defining “generative design”. This approach consists in “creating a reusable workflow that can produce a design or multiple designs.”

“In general, software companies approach generative design with a “black box” solution. They develop the UX and algorithms, you input some load requirements, etc., and they spit out an optimized design. At nTopology, we built a software platform that leverages these algorithms while also letting you use your engineering know-how to build reusable workflows that integrate engineering, automation, and simulation to deliver generative design capabilities. Additionally, generative design is enabled by the new modelling technology in our software that never fails” explains Rothenberg.

Well, the first question is an easy one. Several components are taken into account in a manufacturing process. At what level would you rate the importance of software (on a ten-point scale knowing that 1 is the least important level and 10 is the most important level)? Why?

11 — We are a software company enabling AM 🙂

Seriously though, software plays a critical role: design for additive introduces so many new variables and so much new complexity that software is key to success. To fully realize the benefits of AM, parts must be optimized for the process and design tools must enable greater flexibility and more complexity. Without new software, the AM hardware cannot deliver to its full potential.

Can we combine generative design with topology optimization?

Definitely! We see topology optimization as a “feature” in a complete engineering software solution. The promise of generative design is the ability to produce better designs, faster. Topology optimization is one of a variety of approaches that can be leveraged to deliver a better design, faster.

What are the main advantages of such type of software for additive manufacturing?

When there are new ways of making things, there needs to be software that can take advantage of such capabilities. In the case of additive, there is a whole new design space to explore that traditional tools—which were architected before advanced manufacturing was a thing—struggle to navigate. nTopology was built with these new capabilities in mind and can handle the complexity enabled by additive manufacturing with ease. Software like nTopology enables engineers to fully realize the promise and potential benefits of additive manufacturing.

Does generative design software raise the same issues regarding data than other types of software?

It can; it depends on the output from the software. nTop Platform enables lightweight files that don’t have to get huge when part complexity increases. If the output is a surface-based model or an STL, file size is a bottleneck. We are addressing this by working with all major OEMs to send slice data straight to the machine from our lightweight model. This removes the data bottleneck that STL files create.

In the AM industry, there are various types of software (simulation software, design software, SaaS solution, etc.) that strive to address in their own way the problem of speed & complexity in the additive manufacturing industry. How does nTopology’s software address this issue?

nTop Platform leverages a new technology to model geometry that is faster & more reliable. We leverage parallel processing power (GPU & CPU) to enable speed and we incorporate an open & reusable approach to workflows that enables automation, collaboration, & integration with the existing engineering software stack. Combine this with embedded simulation capabilities and we can deliver unprecedented speed and the ability to handle complexity with ease.

We have just heard that nTopology recently raised $20 Million in funding. What can we expect now from the company?

The purpose for our raise was to scale our technology and company faster. You can expect to see nTop Platform continue to deliver more value to companies looking to innovate faster and to see us addressing applications that move beyond additive into other areas of advanced manufacturing.

Any last words to add?

Yes, mainly that I’m excited that AM has been the catalyst for transforming the engineering software space.

nTop Platform, for example, was built to enable engineers to design better parts regardless of complexity. In doing so, we’ve built a solution that offers benefits way beyond that. nTop Platform lets engineers collaborate more, share workflows and automate low value work (like adding fillets to a part). Additive manufacturing has opened doors for us into enterprise accounts where we can deliver value by leveraging the same capabilities that AM requires.

You can now post free of charge job opportunities in the AM Industry on 3D ADEPT Media. Featured Image via Reuters

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter : Facebook, Twitter, LinkedIn & Instagram !Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com

https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js

(adsbygoogle = window.adsbygoogle || []).push({});