Two weeks ago, GE Additive launched its Manufacturing Partner Network (MPN). The concept seems interesting since it enables collaborating companies to improve their additive manufacturing competences. However, we did not really perceive the key focal points for partners and even the difference between an Open Innovation Program and this MPN. Keith Campbell, Senior Sales Director, GE Additive was willing to play the Q&A game. #OpnionoftheWeek

Two weeks ago, GE Additive launched its Manufacturing Partner Network (MPN). The concept seems interesting since it enables collaborating companies to improve their additive manufacturing competences. However, we did not really perceive the key focal points for partners and even the difference between an Open Innovation Program and this MPN. Keith Campbell, Senior Sales Director, GE Additive was willing to play the Q&A game. #OpnionoftheWeek

What triggers the implementation of the Manufacturing Partner Network?

It comes down to accelerating the adoption of additive manufacturing. Customers from many industries who may not yet wish to industrialize for metal additive manufacturing now or in the future are seeking a reliable source for the supply of prototypes, low rate initial production (LRIP), and series production. The GE Additive Manufacturing Partner Program (MPN), through its Manufacturing Partners (MPs), will provide these resources.

What type of companies might join the network? – Is there a limited number of collaborating companies?

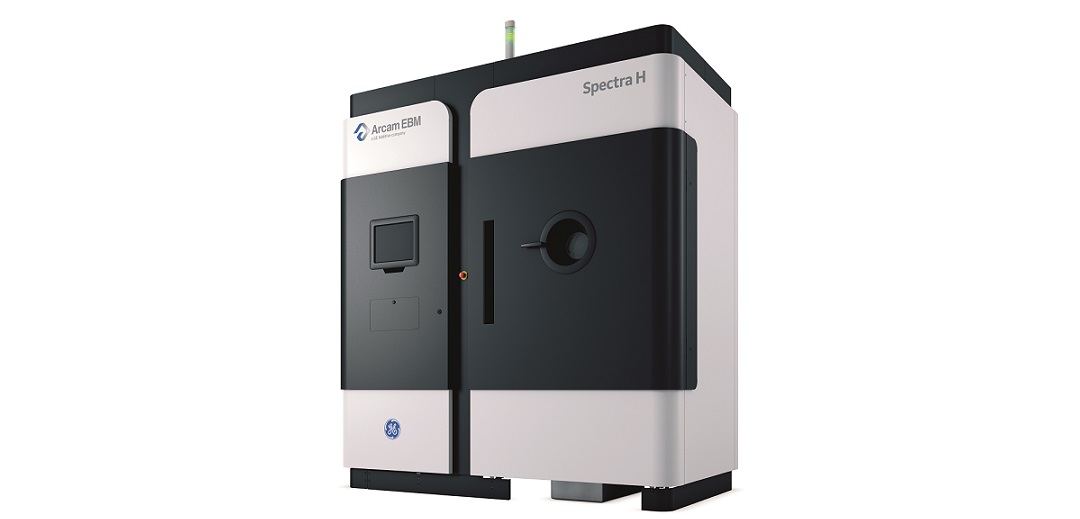

The network will be limited to partners who have demonstrated competency in metal additive manufacturing and post processing and have made a commitment to its long-term growth. These partners will have GE Additive DMLM and Arcam electron beam additive machines for support of the metal additive market.

The MPN will consist of a select group of specialists who have made a long-term commitment to advancing and accelerating the state of additive manufacturing. These partners are not just “build to print” resources, but also can support design for additive through their own resources, and with the support of our AddWorks™ engineering and materials consulting services.

The MPN seems to only benefit collaborating companies. They will benefit from GE Additive’s reputation in the industry in their marketing campaigns as well as from the Direct demand generation through GE’s OEMs. Therefore, what is the main advantage of the MPN for GE Additive?

MPs will have access to GE Additive’s engineering, materials science, and industrialization resources. MPs will also have access to GE Additive’s Customer Experience Center resources in Pittsburgh, in the US and Munich in Germany, for local support with machine training, prototype support, and sharing of best practices. MPs will collaborate within the network through GE Additive MPN symposiums, and the sharing of manufacturing best practices. In addition to additive manufacturing equipment, MPs will have access to the GE Additive ecosystem and its inspection technologies and power management (UPS) systems. MPs will also have the opportunity to participate in machine and software beta programs and will have input to GE Additive’s machine roadmap. The main advantage to the MPN, therefore, is to be best in class through their participation in the network.

What could be the limitations of the network for the AM industry?

Companies will either decide to industrialize for additive, or they will use the services of GE Additive Manufacturing Partners. Some companies will acquire limited additive manufacturing capabilities for development and prototyping, or as a means of rapid development and protection of intellectual property and will either insource or outsource series production. We do not expect to see limitations but opportunities to accelerate implementation and adoption of additive manufacturing for those companies wishing to outsource production to an MP.

How is the MPN different from an Open Innovation Program?

Open Innovation Programs are tools used to bring about the best and most innovative solutions to a wide range of product, technology, and business needs. Our MPN is different in that it is a means for acceleration of additive through a network of competent additive manufacturing resources.

Your last word?

Your last word?

GE Additive is committed to metal additive manufacturing. It has the broadest and deepest portfolio of machines, materials, and engineering services through its AddWorks™ engineering design, materials, and industrialization services. GE Additive’s Manufacturing Partner Program illustrates our commitment to accelerating the g adoption of additive manufacturing across all markets. GE Additive Manufacturing Partners are, and will be, best in class for additive manufacturing, and will have GE Additive’s portfolio of resources available to them to insure their success and the success of their customers.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com