We recently unveiled a first range of creations that sparked the most our interest as part of the Purmundus Challenge. As a reminder, contestants of the 2020 edition of this competition explored the potential of 3D & 4D Printing technologies under the motto “Geometry and Material in Harmony”.

As promised, we are sharing today another range of creations that sparked our interest as part of this challenge.

Alexis Walsh and Justin Hattendorf with EXO Collection

Those two names will certainly sound familiar as three years ago, they developed together the APEX coat, using 3D printing. The following year, the two specialists unveiled an entire collection of APEX that required the mix of traditional craft, 3D printing and simulation.

Based on the same principles, those ground-breaking fashion experts leverage traditional fashion garments as the foundation for the EXO Collection.

What makes the collection unique is the process in which the pieces are designed, assembled, and developed, and the blend between physical and digital environments. Though using traditional paper pattern pieces and cutting fabrics, the pattern shape is translated into a 3D model to place the hardware components. By uploading the pattern pieces digitally, the 3D printed hardware can be perfectly placed within the boundaries of the garment patterns, and can be customized to any size or level of visual complexity. This methodology helps to reduce fabric wastage and unnecessary labor by eliminating the need for producing physical iterations.

Sustainable practices are critical to the design and construction of EXO Collection. The garment hardware, jewelry, and accessories are created through 3D printing in biodegradable plant-based plastics, and Selective Laser Sintering, a zero-waste 3D printing method. The garments are sewn and assembled by hand, made locally in NYC. The fabric pattern pieces are specially arranged to minimize fabric waste during pattern cutting and to utilize as much of the fabric as possible. The products are all made-to-order and printed on-demand. This business practice eliminates the need for stock and excess materials.

To augment the collection’s 3D printed jewelry line, there is an Instagram AR filter so that consumers can try on the jewelry pieces before they buy. Because the designs are created completely within a virtual environment, the interactive experience of AR invites consumers to participate with physical designs in a virtual space as a seamless continuation of the design experience.

HUHN cycles by Ralf Holleis

Bikes have been a great part of 3D printing applications this year, especially because most achievements in this area are made possible thanks to Carbon Fiber or Titanium materials. It would have been tough to not see a contestant with an innovation in this field.

Framebuilder Ralf Holleis on his side, has opted for the use of titanium for the manufacturing of bikes’ components. He combines the advantages of super light Titanium tubes and connects them with additive manufactured Lugs. This results in extremely stiff joints as they can be designed according to the forces within a bicycle frame, and distributes them equally.

No tools are required. Furthermore, functions like cable guiding, seat clamps, bearing housings as well as additional material for welding can be integrated in the design and make the work of the Framebuilder a lot easier.

Adjusting temperature in a car thanks to integrated 3D printed heating panels

This innovation is like a dream come true for those who are never satisfied with their vehicle’s temperature.

A team from TU Braunschweig – Institut für Konstruktionstechnik has explored the potential of the garnish molding to integrate additively manufactured panels for conformal heat generation using multi-material design.

The utilized material – a composite filled with carbon nanotubes – has a linear current-voltage characteristic that allows surface temperature to be controlled via voltage. A specific adjustment of the current-voltage characteristic is achieved by defining the electrical resistance through both geometry of the heating panel and process parameters like raster angle orientation. In this way, a required temperature can be set via geometry and process parameters as a function of a specified input voltage. At 12 V, approximately 45 °C is reached after 60 s and approximately 65 °C after 180 s respectively.

Thus, 3D printing provides an individual adjustment of the resulting electrical properties of the heating panels according to requirements by both, material choice and by geometry as well as process parameters.

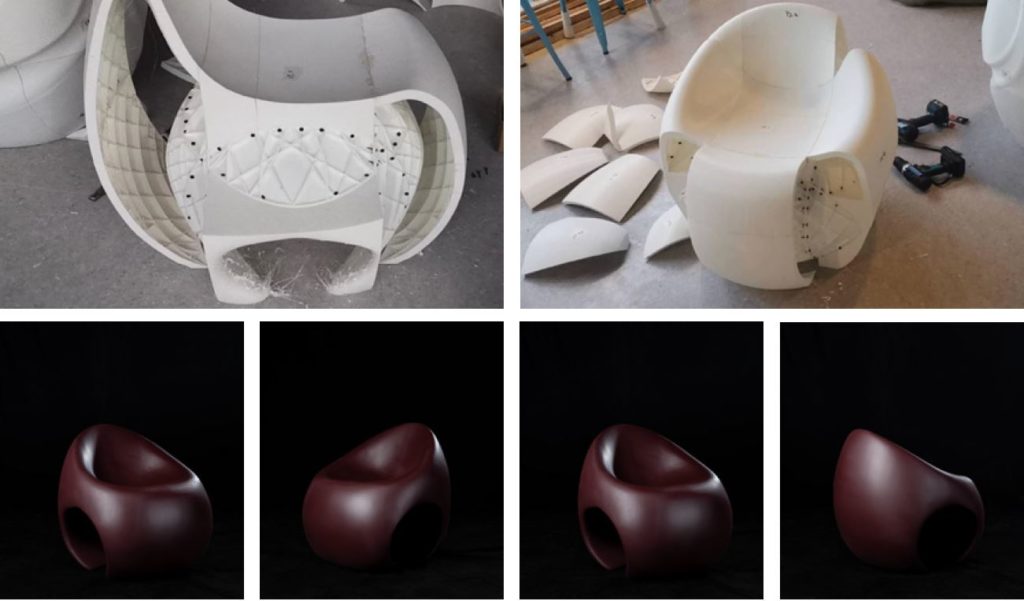

Spazio Z Design Studio I Zihan Zhao

A China-based studio has developed its 3D printing pellet extruder for the fabrication of “Zero Chair”.

The Zero chair comes from the fact that the arc between the two legs of the chair creates a shape similar to the Arabic number „0“, and the curve of the chair surface and the back of the chair also perfectly outlines the shape of the number „0“, which is the mutual integration of geometry, 3D printing and material forming.

At the technical level, they used PA66 thermoplastic material and resin for compounding, which improves the physical properties of 3D printing material, and the surface treatment effect has reach treatment effect has reached the level of productied the level of productizzationation. It can replace traditional production methods to put in mass productiontraditional production methods to put in mass production.

An ice-climbing device

Maximilian Klyk, a Student research assistant at Darmstadt University of Applied Sciences, has developed a technical ice-climbing device as part of his diploma in industrial design.

There is always a contradiction when it comes to ice-climbing tools. They should be as light as possible in order to conserve strength and energy when climbing, because both the striking motion and overcoming the vertical distance are very tiring over time. On the other hand, the tools need to have a certain weight so that they have enough momentum to penetrate the ice and improve their precision.

Additive manufacturing makes it possible to reduce the weight while also integrating an acceleration system, resulting in impact energy that is comparable with heavy equipment produced using conventional methods, thanks to optimised, lightweight structures. This acceleration system consists of a ball that runs along a track that is integrated into the lightweight structure. When the tool is swung, centrifugal force pushes the ball towards the head, where the impact transfers momentum and energy to the pick.

Arch is made from aluminium ALSi10Mg, using the SLM process. The pick is made from tempered steel using conventional forging methods. A layer of rubber is also applied to the handle to improve heat insulation and grip. The project involved the creation of a prototype, in order to test the tool and serve as a design model.

Remember, you can post free of charge job opportunities in the AM Industry on 3D ADEPT Media or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com