Under the theme “3D printing gears up our future”, 34 finalists took part in the Purmundus Challenge, that was held for the 6th time in Frankfurt, during the Formnext event. This challenge that recognizes products of the future in 3D printing awarded 6 gold trophies to finalists.

This year’s winners are:

1st prize: Keyed wind instrument by Ricardo Simian from 3D Music Instrulents.

One barrier that still needs to be overcome is the difficulty to be able to reach the holes with the fingers. A barrier that is overcome thanks to the flexibility properties of SLS 3D-printed materials which allows the production of functional keys without any additional mechanism nor spring. When carefully designed keyed instruments can be printed with incorporated keys.

2nd prize: Adidas Grit by Aarish Netarwala

Grit is a pair of resistance training shoes, that replicates the experience of training on soft sand.

3rd prize: Bionisch inspirierter Kombibrenner

Dr. Christoph Kiener & Manuel Biedermann from Siemens AG, Corporate Technology took advantage of additive manufacturing to “reinvent” products and components and in so doing to make an important contribution to the efficiency and sustainability of future systems.

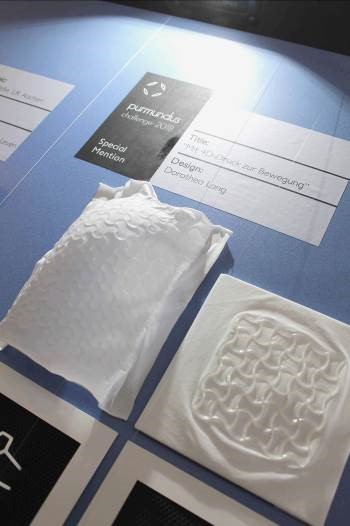

Special Mention: “Mit 4D-Druck zur Bewegung” by Dorothea Lang.

The focus of the Master’s thesis on “Using 4D printing to achieve movement” was on developing dynamic, form-changing and smart textiles. The aim was to pick up on the idea of “4D printing” in order to create functional, adaptive and active properties in fabrics. A large number of experimental material studies were carried out using 3D printing in order to investigate how to finish a textile surface with a 3D imprint in order to create a particular movement.

Innovation Prize: Fungus-like additive materials.

Javier G. Fernandez and Stylianos Dritsas from Singapore University of Technology and Design realized the missing piece of circular economy is large scale and sustainable 3D printing with the most ubiquitous natural materials.

The Public Choice Award goes to the world’s first printed bathtub made of sand by Sebastian Hermann from the Bavaria-based startup Sandhelden GmbH & Co. KG.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter!

Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com