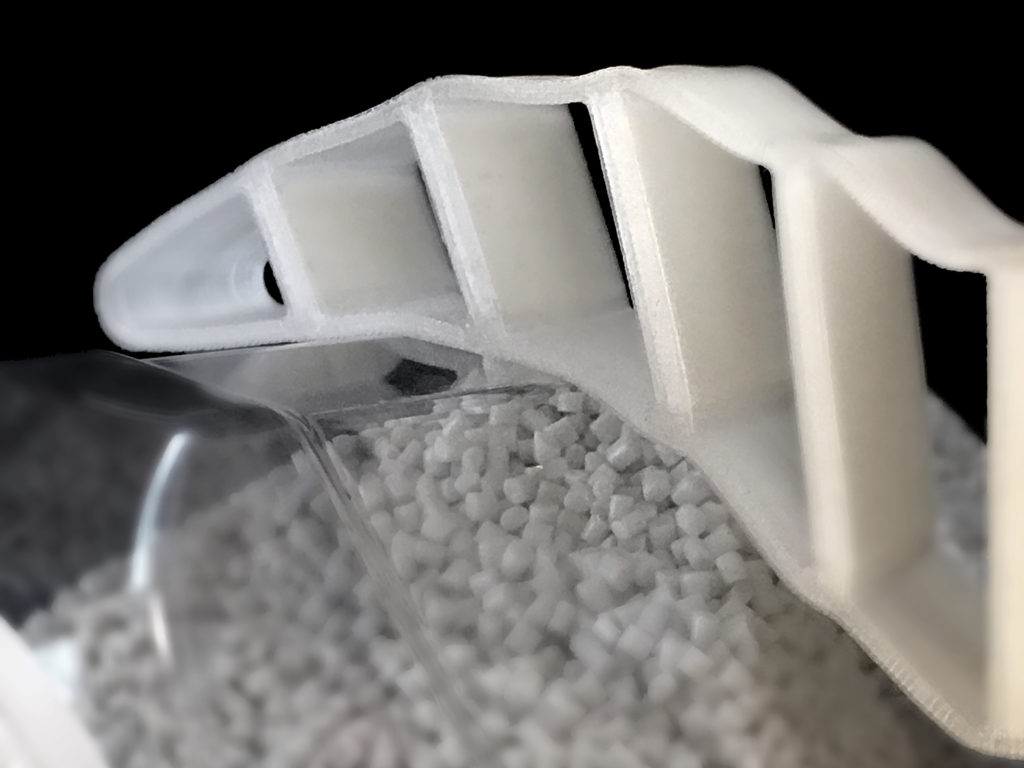

Also known as thermoplastic rubber, thermoplastic elastomers (TPE) are used to produce the soft parts of objects such as toothbrushes or razors, sports equipment, airbag cases, dashboard covers of cars and many others.

The automotive industry as well as various industries increasingly exploit this material hence the rapid growth of this sector. Pollen AM, manufacturer of the Pam technology, aka “Pellet Additive Manufacturing”, completes its offering to the additive manufacturing industry by exploiting this material.

Pam Series P and the potential of TPE

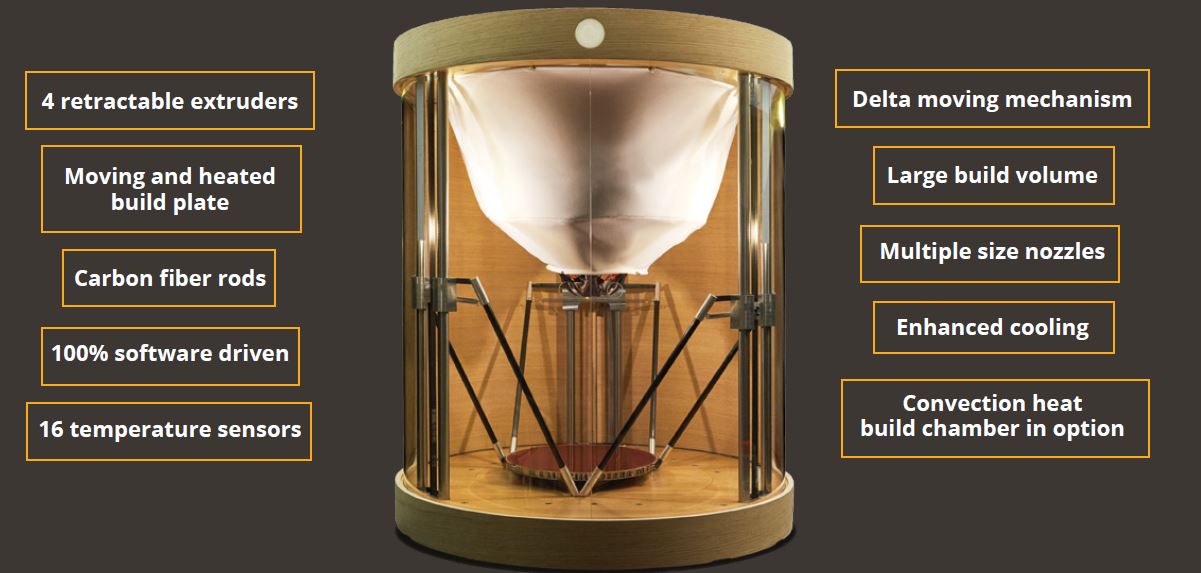

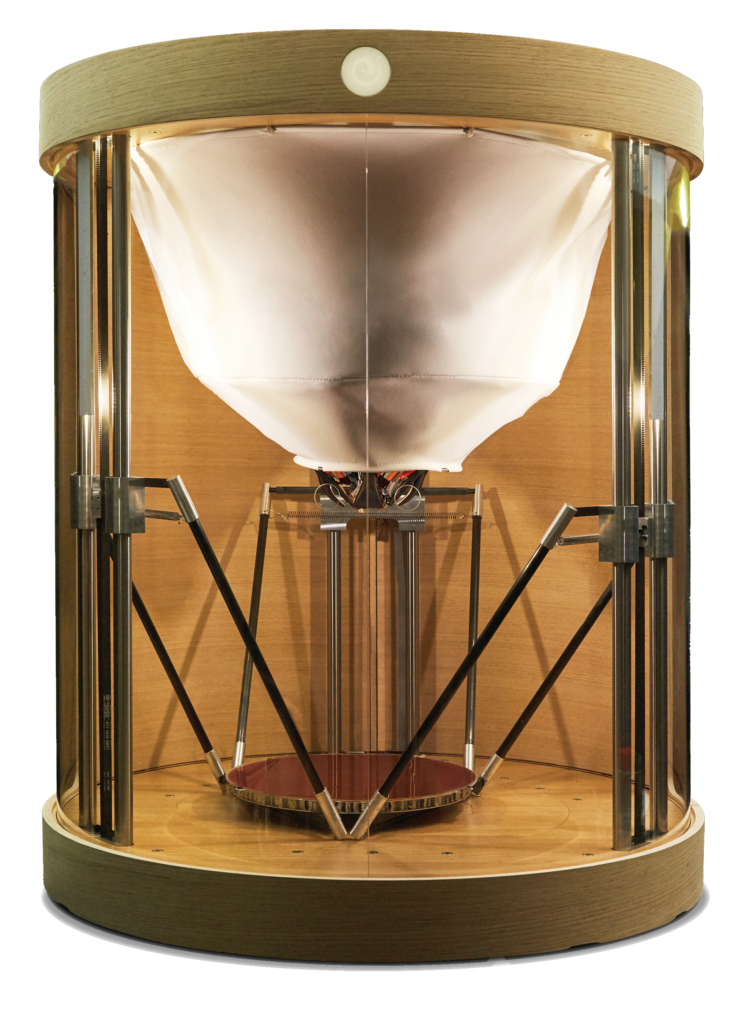

Active in the additive manufacturing industry for over 5 years, Pollen AM designs the Pam Series P 3D printers. The company explains that its system would be able to 3D print TPE with no hardness limits: from Shore00 to ShoreD.

The 3D printer integrates 4 extruders, WI-Fi connectivity and can reach a maximum temperature of 400°C. It works with Cura & Honeyprint software and is compatible with stl.obj.3mf files.

Speaking of the printing process, Pollen AM said that “it is at the level of the extrusion unit, equiped with interchangeable diameter nozzle (D) that the new phase of transformation begins: the deposition and the solidification of the material. The build plate moves to allow creation of the 3-dimensional part.”

Speaking of the printing process, Pollen AM said that “it is at the level of the extrusion unit, equiped with interchangeable diameter nozzle (D) that the new phase of transformation begins: the deposition and the solidification of the material. The build plate moves to allow creation of the 3-dimensional part.”

Combining thermoplastic elastomers with Pollen AM’s 3D printing technology would be an interesting choice for industrial applications. Indeed, the material offers a very good chemical resistance, is recyclable and compatible with other thermoplastics. Lastly its mechanical properties can be compared to injection molding.

Until now, TPE are not widely exploited in the AM industry; a state of the market that Pollen AM aims to change with this offer.

For further information about 3D Printing, follow us on our social networks and subscribe to our newsletter! Would you like to be featured in the next issue of our digital magazine? Send us an email at contact@3dadept.com