Phase3D, an expert in Additive Manufacturing (AM) in-situ inspection technology, adds Fringe Qualification to its Fringe Inspection product suite. This tool would enable manufacturers to certify and control AM builds in real-time across their entire fleet of machines.

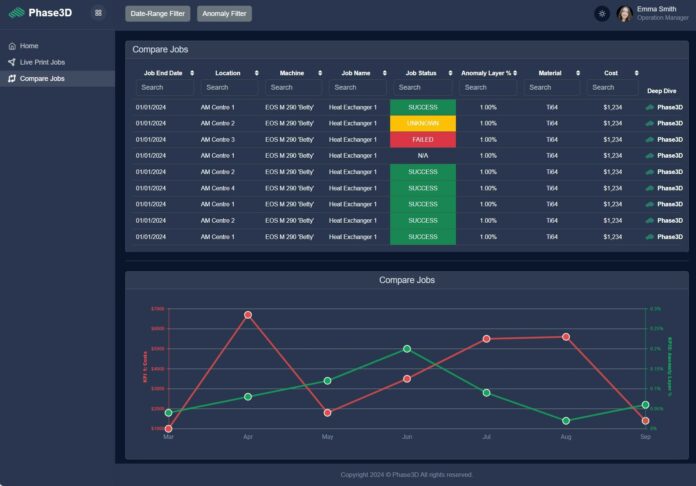

Fringe Qualification enables automated, layer-by-layer inspection capabilities across multiple 3D printers. This tool is important in sectors such as aerospace, medical devices, and defense manufacturing, where it is necessary to achieve part quality at scale.

The new system integrates seamlessly with Phase3D’s existing Fringe Operator visualization and inspection software, creating a comprehensive solution for build certification that drastically reduces post-processing costs and accelerates delivery timelines.

Key features of Fringe Qualification include real-time inspection across multiple machines, automated quality checks using historical build data, instant out-of-specification alerts, and detailed build reports.

Fringe Qualification leverages structured light fringe projection technology to create precise, micron-level height maps of each layer, offering unmatched accuracy in surface measurement. This objective data—captured by Phase3D’s Fringe Inspection system—provides quantifiable metrics for real-time decision-making, setting it apart from AI/ML-based methods. Instead, Phase3D’s metrology approach ensures trusted, repeatable data for maintaining the highest industry standards, a press communication reads.

Phase3D will demonstrate Fringe Qualification at Formnext 2024, Booth E58 in Hall 11.0.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter: Facebook, Twitter, LinkedIn & Instagram! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com