OSPREY, a company that has made the design & fabrication of innovative backpacks its core business, unveils a new series of backpacks fabricated using 3D printing.

This might be a premiere for the brand but it’s not really the case for the backpacking industry that first saw the use of 3D printing in the development of a recyclable outdoor backpack prototype with TPU monomer material. Interestingly, both projects have been industrialized and produced by OECHSLER AG, a plastics technology group that was also involved in the development of sustainable outdoor backpacks.

According to Osprey founder Mike Pfotenhauer, this new collection is the result of a two-year R&D work with development teams.

“Traditional manufacturing methods teach us that in order to push the boundaries of innovation, product development timelines need to be extended. The development of Osprey UNLTD proved the exact opposite. The entire process using Carbon DLS took about one year with only six months for us to iterate on the design, enabling Osprey to take this innovative product to market faster,” said Carbon co-founder Phil DeSimone, Carbon´s co-founder.

“Osprey UNLTD is the manifestation of Osprey’s approach to innovation. In developing Osprey UNLTD, we removed the shackles of commercialisation and production schedules to move beyond traditional manufacturing technologies ushering in a new era of backpack design and the ultimate backpacking experience,” contributed Rob BonDurant, vice president of Marketing for Osprey Packs.

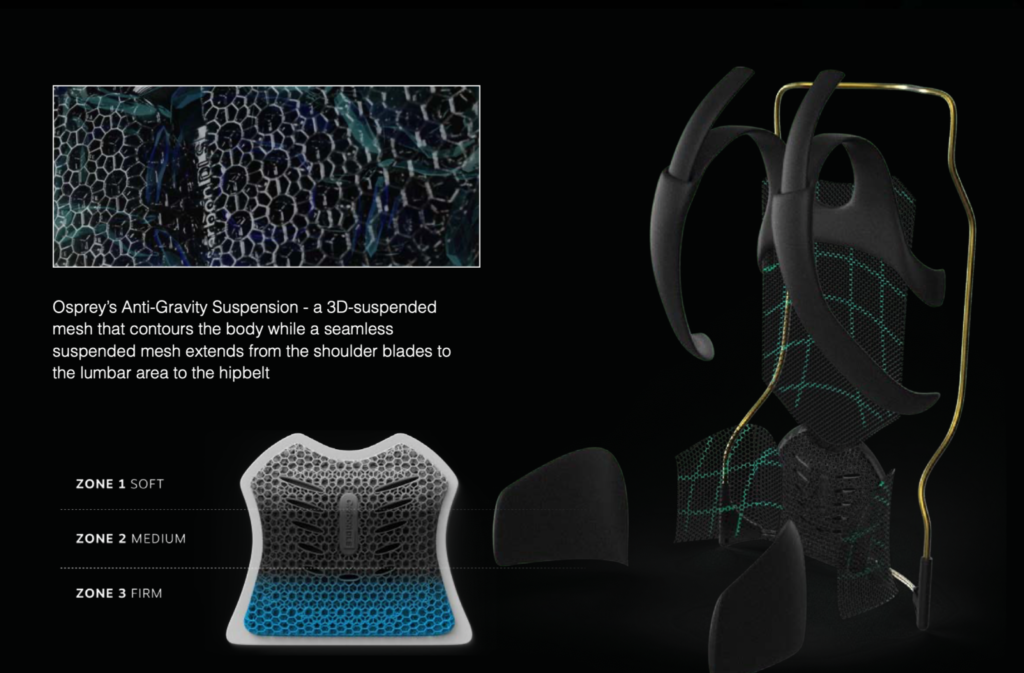

From a technical standpoint, the structure support features a high Carbon Stainless Steel frame and Polycarbonate Vacuum Formed Framesheet support the load. The use of 3D printing has been efficient at the ventilation level. Carbon DLS TechnologyTM used for product development enabled to 3D print the Fitscape™ lumbar cushion which delivers supreme ventilation, fine-tuned support and anti-slip grip.

For a company like OSPREY which is usually close to nature, as are their users, it makes sense to naturally see sustainability at the heart of their product development. In this vein, the company comments:

“From raw materials and chemistry benchmarks to progressive factory code of conduct agreements and programs that extend a product’s end of life, Osprey is looking at every aspect of their business to ensure they leave as little trace possible. Osprey is dedicated to creating innovative, high performance, sustainable gear that reflects the brand’s love of adventure, devotion to the outdoors and steadfast resolve to leave the world better than they found it.”

The backpacks start at £650.00. They are available in two colours, blue and green, and for both the morphology of men and women.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com