Westinghouse Electric Company, a company that provides a wide range of nuclear power plant products and services to utilities throughout the world, continues to push the use of AM in the nuclear industry.

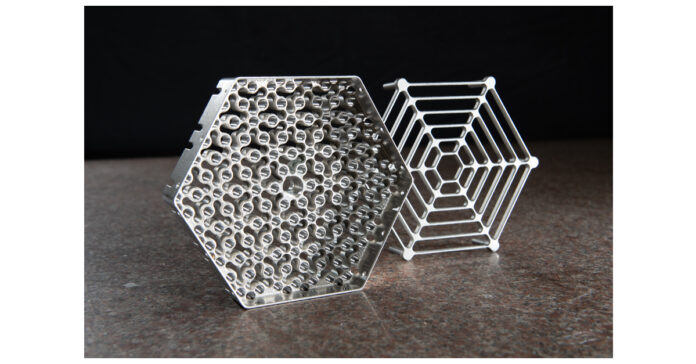

The company’s recent milestone is the manufacture of its 1,000th fuel flow plate using Additive Manufacturing (AM). It represents an industry achievement as the first-ever safety-related AM components to enter serial production.

As a reminder, the company installed the first metal 3D-printed thimble plugging device in a nuclear plant and installed another one two years ago in another nuclear plant.

The AM flow plates we are referring to today, are installed in VVER-440 fuel assemblies, enabling a redesign of the assemblies’ bottom part which results in a more robust performance.

“This achievement showcases the development of additive manufacturing from prototyping to full-scale production, generating tangible value for our customers,” said Lou Martínez Sancho, Westinghouse Chief Technology Officer and Executive Vice President, R&D and Innovation. “This marks another Westinghouse pioneering achievement in AM Technology holding the commitment to strengthen safety, efficiency, sustainability and energy security.”

This milestone is a continuation of Westinghouse’s leadership in deploying AM in the nuclear industry to achieve cost and lead-time reductions and enable cutting-edge solutions for energy generation.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com