A few months ago, Massivit made headlines when it unveiled its second-generation technology, the Cast-In-Motion technology. With a key focus on composite materials manufacturing, the process aims to address tooling bottlenecks by automating and decreasing conventional composites tooling processes by directly printing and casting the mold.

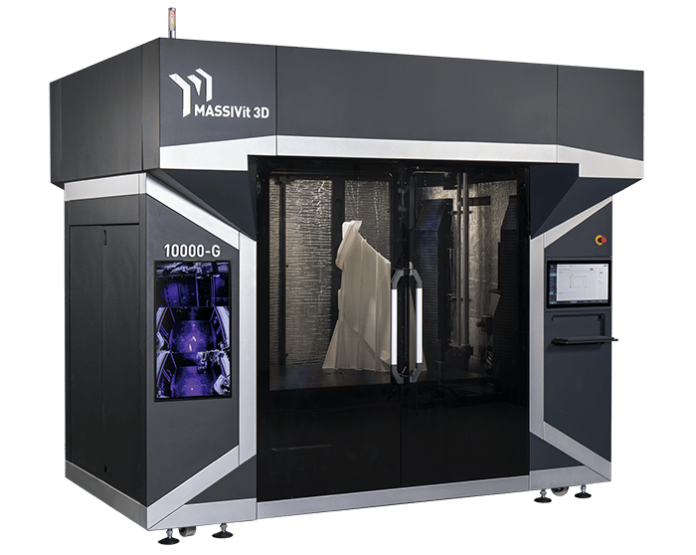

The Massivit 10000 is the flagship product unveiled for this technology. During the recent Formnext, the developer of large-scale 3D printing solutions launched the Massivit 10000-G. In addition to providing the wide range of composite manufacturing applications already available on the Massivit 10000, the newest member to the family integrates a new feature providing access to Massivit 3D’s set of Dimengel photo polymer materials that have until now been used with the company’s Gel Dispensing Printing product line. This means that users could directly include direct custom manufacturing and functional prototyping as part of the services.

As far as applications are concerned, Massivit has been acknowledged for the hype it created across the entertainment, fashion, and visual communication industries. As AM remains manufacturing-focused, it would be interesting to discover what Massivit technology can do in other areas. In this specific case, the company promises tooling applications for Thermoforming, Resin Transfer Molding, and Reaction Injection Molding. Furthermore, according to Massivit, Dimengel materials respond to essential industry requirements such as flame retardancy, high-definition production, and a reduction in waste.

One of the materials that is already available for this product line – and the Dispensing Printing line is a high-impact 3D printing material named Dimengel 400. The company says it is the strongest and toughest in its portfolio, which makes it a great fit for large, strong, and stiff end parts as well as functional prototypes, jigs and fixtures. Ideal for parts that can withstand high temperatures, its mechanical properties deliver double the impact resistance of existing high-performance Dimengel materials, as well as a high Heat Deflection Temperature (HDT).

“We are excited to introduce our latest large-scale 3D printing technologies designed to accelerate digital transformation in the manufacturing market. In particular, the composite manufacturing arena is steeped in labor-intensive and costly processes that are long overdue for innovation”, commented Massivit 3D’s CEO, Erez Zimerman. Our aim is to facilitate far more efficient processes using industrial-grade materials to maximize the true potential of composite materials.”

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure to send it to contact@3dadept.com