Providing engineers the freedom of Additive Manufacturing with a 3D printer that has been fabricated like a tooling machine

The more composite 3D printing becomes appealing for industries, the more manufacturers invest extra miles to deliver multi-faceted solutions that promise a lot of benefits to users.

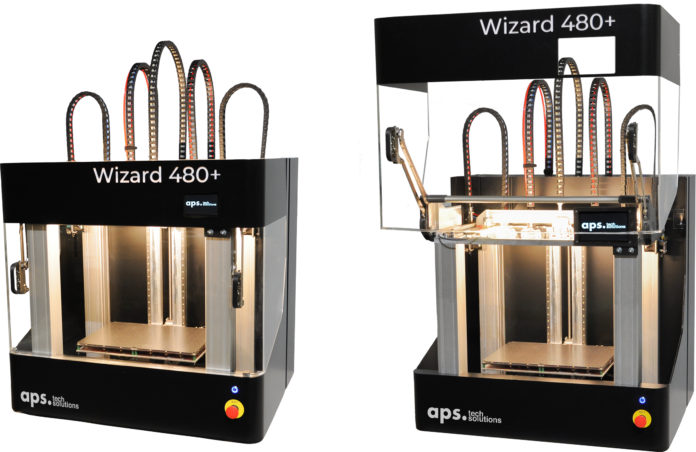

The latest manufacturer that is taking its first steps in this segment is APS TechSolutions, a new subsidiary of APS which stands for Automatisierte Produktions Systeme GmbH – Automated Production Systems and which was originally founded in 1987. Backed by its parent company’sdecades of experience acrossengineering, 3D water jet cutting, robotics, composites, and light weight solutions, the team at APS TechSolutions brings to the market the Wizard 480+, an additive manufacturing machine that delivers multi-production capabilities.

The team has spent the last five years developing the Wizard 480+, assessing its capabilities and the value the machine could bring to vertical industries; an approach that we fully respect and understand as today, APS TechSolutions can now operate as a standalone company. In this vein, during the course of this month, the startup will officially be incorporated as an independent company.

The “engineering magic” into a dedicated-composite 3D printing solution

Have you ever realized that most machines unveiled on this market often have complicated names that are difficult to remember? Well, this will certainly not be the case for the Wizard 480+ whose name intrigues.

The manufacturer’s choice for this name is relatively simple to understand: “embodying the engineering magic and the solution’s ability to print every filament available on the market, FDM but also continuous filaments, due to the machine’s modular setup.”

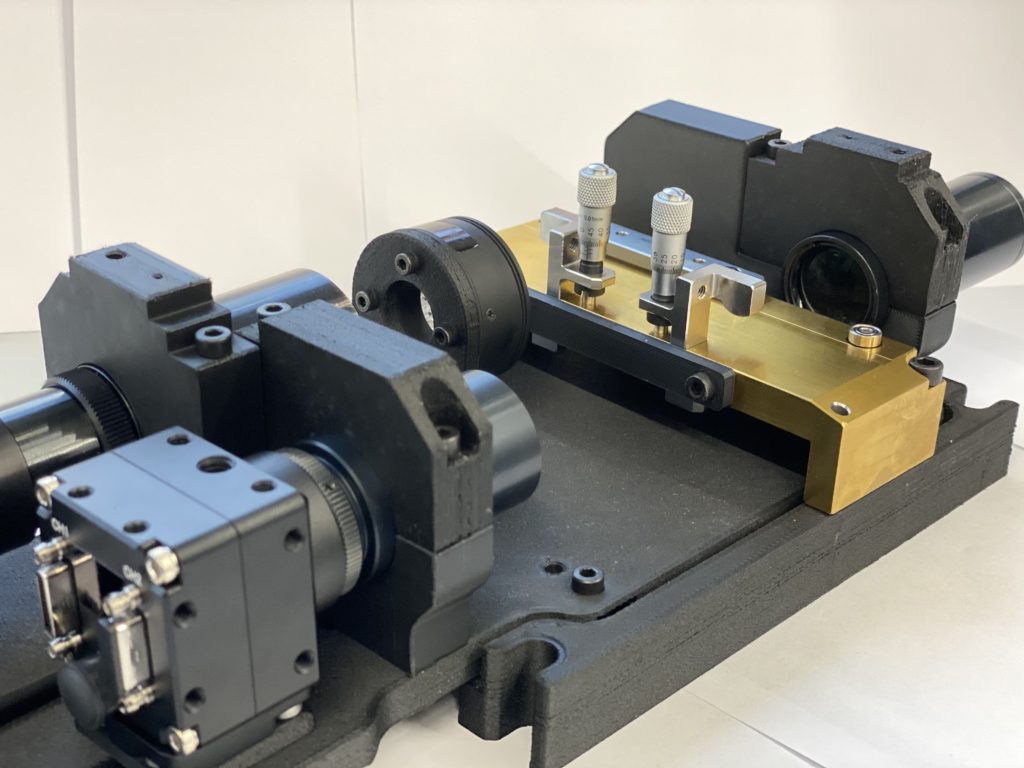

Beyond a relatively simple design, a first look at the Wizard 480+ reveals four printheads, a manufacturing approach chosen on purpose, as the machine has been fabricated like a tooling machine. Indeed, manufacturers that directly develop desktop 3D printer use to opt for a multi-nozzle approach when it comes to improving the production capabilities of their machine.

With a working speed of 500mm/s, Wampl explains that the toolchanger enables a fast tool change (under 3 seconds), and delivers several advantages from a materials standpoint:

“The toolchanger allows for the manufacturing of multiple fiber types or polymers, or the use of dedicated support material to achieve optimum quality. It could also enable the use of the same material, but with different nozzle diameters including larger nozzles for the infill, for example”, Wampl notes.

Furthermore, several features can be optimized and adjustable so that the printheads can be compatible with a given material. These features include for instance the heating zone, driving system, as well as the nozzles to have the optimal printing process. This means therefore that, the operator would just need to upgrade the 3D printer or change the printheads if he wants to use a special filament.

Most importantly, “all printheads are water-cooled and reach temperatures up to 500 °C. The CFF printhead is an open system which means continuous filaments from other suppliers can be printed, – in addition to copper wires (and other metal wires)”, the expert states.

-

ceramic -

copper

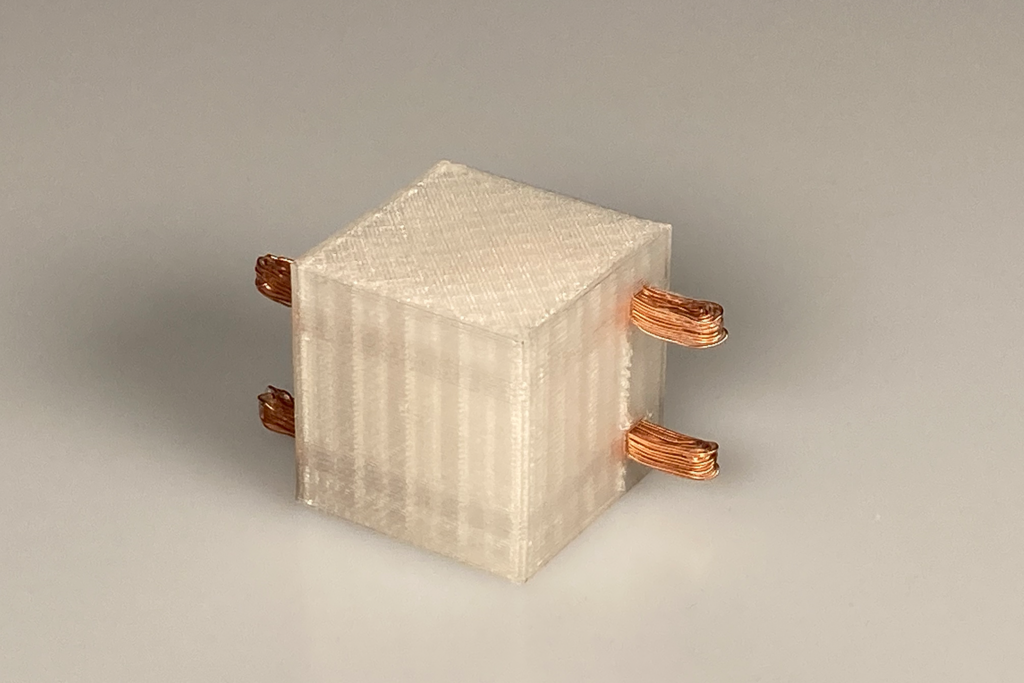

Apart from these materials benefits, it should be noted that the Wizard 480+ also stands out from the crowd due to its ability to combine the strengths of Continuous Fiber Printing and FDM within the same platform.

The patent pending process for the manufacturing of continuous filaments (APS-CFF) requires continuous filaments to be cut during the manufacturing process. Moreover, “with the CFF process with a minimal length which needs to be printed (20mm), the turning radius of the process is minimal which means we can place fibers parallel”, Wampl points out.

Combining those two processes within the same platform could lead to the development of several applications and enhance the properties of 3D printed parts. However, their combination remains optional as the user can always decide on the way he wants his machine to be setup.

So, what can this 3D printer do?

If you are a regular reader of 3D ADEPT, you certainly know that we go beyond the specifications to discover what every machine can do. As in the end, applications are what drives the market.

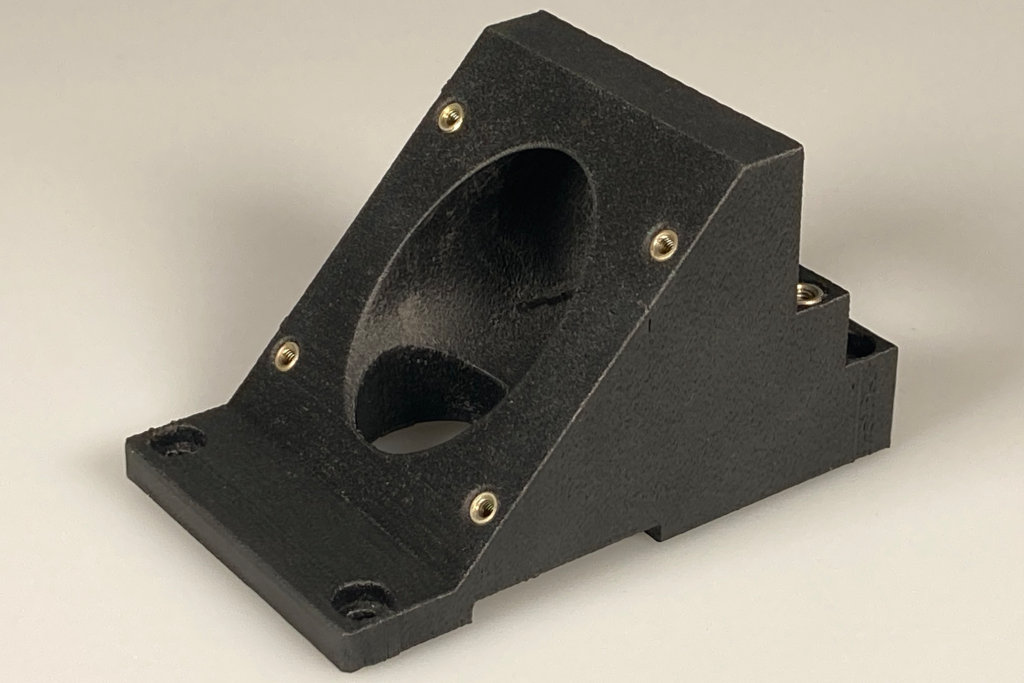

In this specific case, we’ve discovered that FRITZ STEPPER GMBH & CO. KG, an expert in modular stamping tools and advanced surface coatings, has leveraged the Wizard 480+ for the manufacture of a spare part. Initially made of aluminium and produced by CNC milling, the spare part – a camera module for a stamping tool – has entirely been 3D printed without any changes.

The new part has been produced using PA-CF (FFF) for the outer shell, Continuous Carbon Fiber (CFF) for the reinforcement inside as well as a water-soluble support material (FFF) for the complex geometry.

“According to Fritz Stepper GmbH, the Wizard reproducibly produces components with H7/h7 fits (>10mm)”, the APS TechSolutions reports.

Wampl also lays emphasis on the fact that “post-processing greatly depends on the materials and the user approach. You can use water-soluble support material or support structures: both have their benefits and require different post processing tasks. For FDM parts with short carbon fibers, tempering is very advisable while for metal or ceramic green parts, you need debinding and sintering”.

The next step?

APS TechSolutions in bringing to the market a flagship product, made for industrial use, with versatility in mind, and in Austria. Available at a starting price of € 100.000,-, this first overview reveals capabilities that would be appealing to more than one vertical industry.

Right now, the team will focus on enhancing the system and its capabilities, but from what we have already learned, this is a solution which is likely to redefinecomposite 3D printing applications.

All images: courtesy of APS TechSolutions. Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com