You have certainly heard about LAKE when we recently covered the production of 3D-printed pickleball paddles, the 15th sport discipline to leverage 3D printing. Based on AZUL 3D’s high-area rapid printing (HARP) technology, LAKE is the first commercial 3D printer of the American machine manufacturer.

As a reminder, HARP is a proprietary version of stereolithographic printing that converts liquid plastic into solid objects using ultraviolet light. With this technology, the machine can print complex geometries at rapid speeds using proprietary materials. To illustrate how fast the machine can produce, the machine manufacturer reminds that during the pandemic for instance, 5,000 face shields were produced in 60 hours for healthcare workers. That meant every 6 minutes, Azul 3D was able to get 8 face shields off the printer and begin starting the next round of printing.

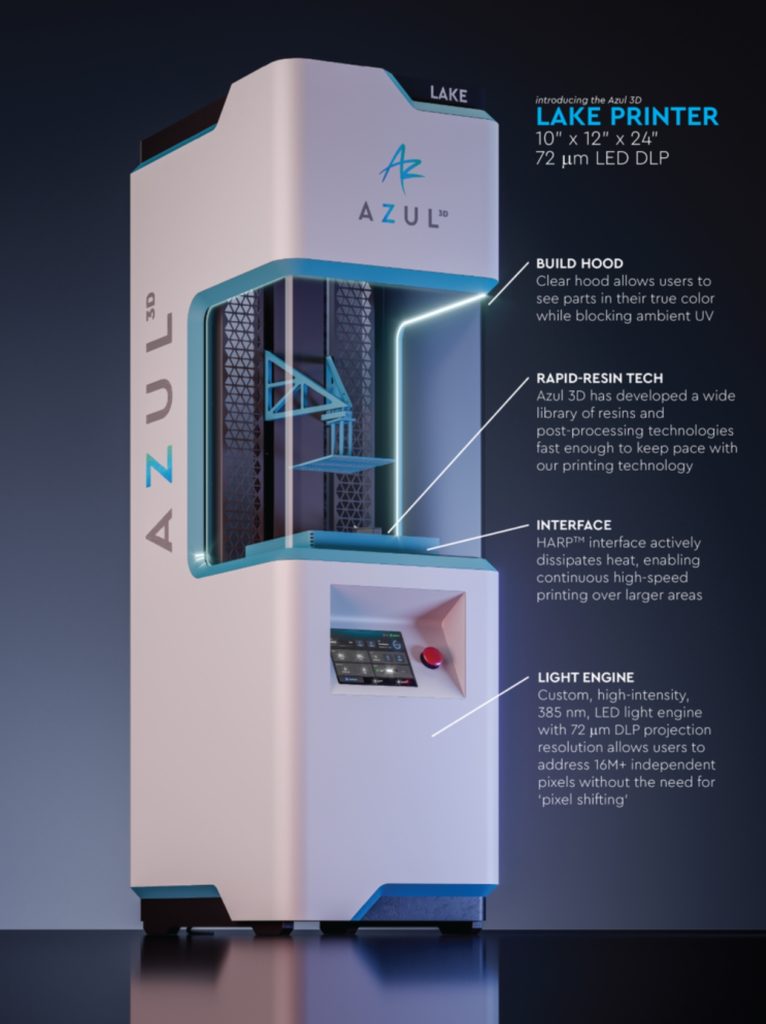

With a print area of 10” by 12” by 24” (25 cm x 30 x 60 cm), the machine integrates a custom, high-intensity LED light engine that enables operators to address 16 million independent pixels without the need for “pixel shifting” used by other projectors.

“In the past year, manufacturers have been throttled by supply chain disruptions,” said Cody Petersen, CEO of Azul 3D. “At the same time, everyone is demanding more highly engineered solutions immediately. The LAKE printer offers a revolutionary solution to both problems and is the first step in industrializing additive manufacturing at scale.”

The company said in a press release that the LAKE printer is the first in a series of printers that it will unveil in the coming years. We might also expect to see the SEA, a new generation of 3D printers that will deliver four times the print area, allowing manufacturers to print even bigger parts or products.

Remember, you can post job opportunities in the AM Industry on 3D ADEPT Media free of charge or look for a job via our job board. Make sure to follow us on our social networks and subscribe to our weekly newsletter : Facebook, Twitter, LinkedIn & Instagram ! If you want to be featured in the next issue of our digital magazine or if you hear a story that needs to be heard, make sure you send it to contact@3dadept.com