Hadrian, the advanced manufacturing company building AI-powered factories for America, launches Hadrian Additive, a division that aims to deliver scalable, production-ready additive manufacturing capacity for the U.S. Defense Industrial Base and allied partners.

The new division expands Hadrian’s Opus factory platform to include additive manufacturing systems built for qualification, repeatability, and sustained throughput, enabling defense programs to move from validated designs into reliable, at-scale production.

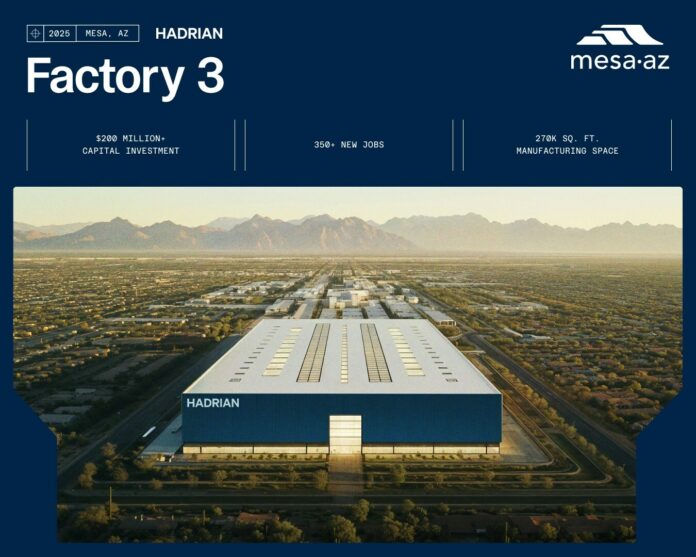

Initial additive manufacturing capacity is expected to come online in 2026 as part of Hadrian’s expanding U.S. factory footprint.

Hadrian Additive integrates additive manufacturing directly into the company’s existing factory model, allowing additive production to support mission-critical systems within a single, end-to-end manufacturing environment.

“America’s defense industrial base needs additive manufacturing that works in real production, not just in prototypes,” said Chris Power, Founder and CEO of Hadrian. “We’re building this capacity the same way we build our factories—engineered for qualification, throughput, and speed—so critical programs can scale when it matters most.”

The division will be led by Matthew Parker, Vice President of Additive Manufacturing at Hadrian, and will focus on meeting the reliability, quality, and traceability requirements of defense and national security programs.

“Additive manufacturing only becomes strategic when it’s industrialized,” Parker said. “Hadrian Additive is designed as a production system from day one, integrated with our factory stack and capable of scaling as demand grows.”

The launch of Hadrian Additive builds on the company’s recent factory expansions and manufacturing initiatives, further strengthening domestic production capacity for priority defense programs.

*We curate insights that matter to help you grow in your AM journey. Receive them once a week, straight to your inbox. Subscribe to our weekly newsletter.